Mitsubishi Evolution X. Manual - part 395

DIAGNOSIS <TC-SST>

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-37

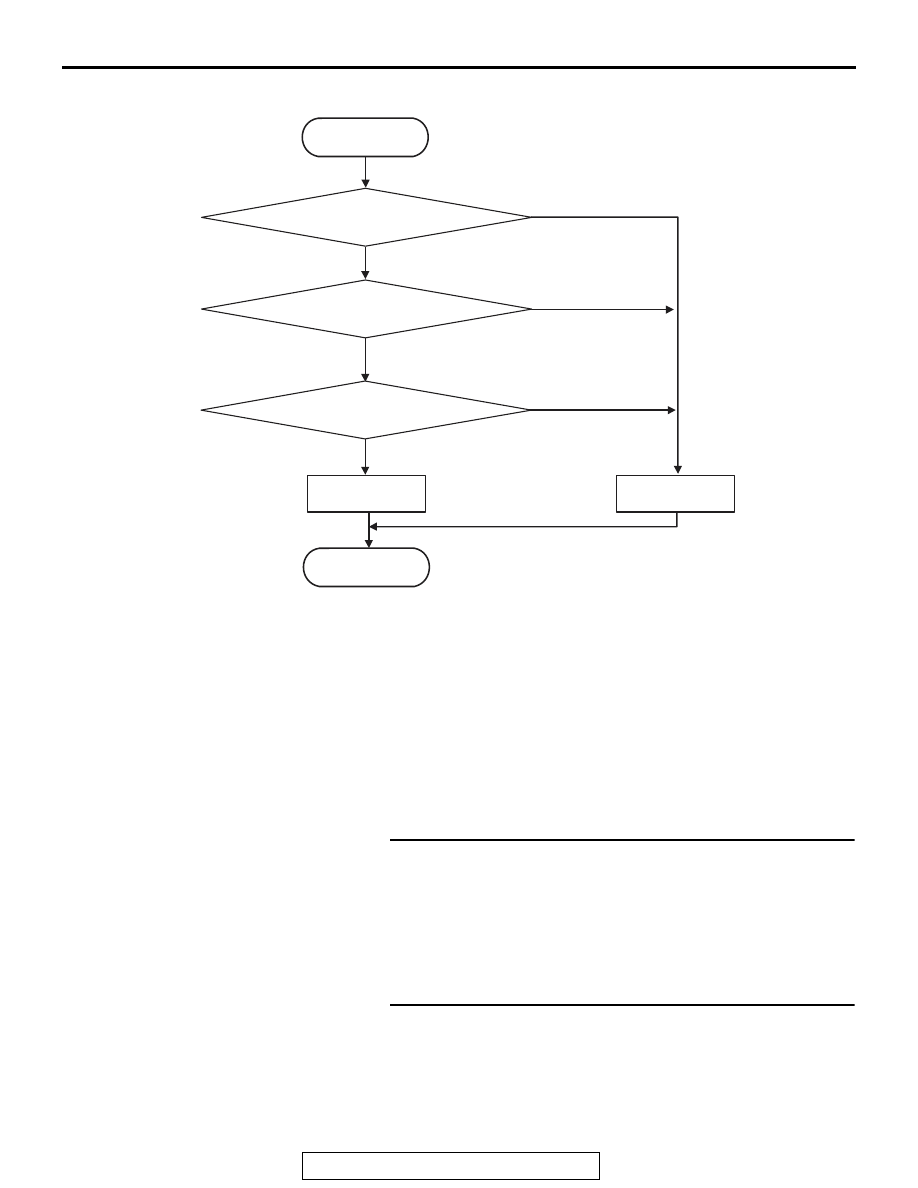

LOGIC FLOW CHARTS (Monitor Sequence)

.

DTC SET CONDITIONS

Check Conditions

• Voltage of battery: 8 V or more.

• Voltage of battery: 16.5 V or less.

JUDGMENT CRITERIA

• FET (Field Effect Transistor) output: 1 V or more.

(1 second)

.

OBD-II DRIVE CYCLE PATTERN

The FET channel output remains 1 V or less for 1

second.

.

PROBABLE CAUSES

• Malfunction of TC-SST-ECU

DIAGNOSTIC PROCEDURE

STEP 1. Scan tool CAN bus diagnostics

Using scan tool MB991958, diagnose the CAN bus lines.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines. (Refer to GROUP 54C

−

Troubleshooting

.) After repairing the CAN

bus line, go to Step 2.

STEP 2. Check whether the DTC is reset.

Q: Is DTC No. P0758 set?

YES : Replace the TC-SST assembly. (Refer to

NO : Intermittent malfunction. (Refer to GROUP 00

− How

to Cope with Intermittent Malfunction

.)

AC710622

START

No

Yes

Yes

Good

Malfunction

END

Monitoring condition met

No

Continuous failure

for 1 sec

No

Yes

FET* output > 1 V

*FET : Field Effect Transistor