Mitsubishi Evolution X. Manual - part 245

STARTING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-33

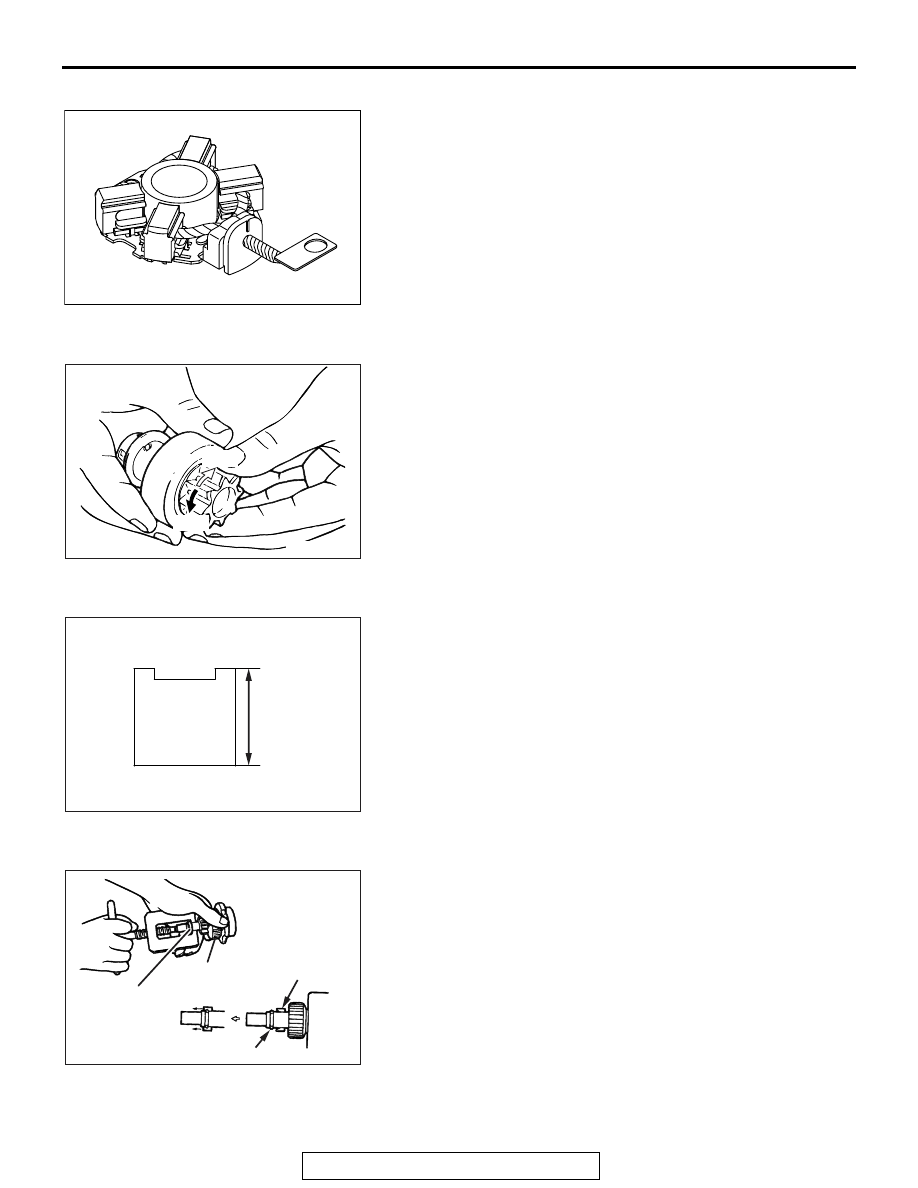

BRUSH HOLDER

AK201187

Push the brush into the brush holder to make sure that the

spring is working on the brush.

If the spring is not working, replace the brush holder.

.

OVERRUNNING CLUTCH

AK304691

Free

Lock

AG

1. Make sure that the pinion cannot be turned

counterclockwise, and can be turned clockwise freely.

2. Check the pinion for abnormal wear and damage.

.

BRUSHES

AK202846

Brush

height

AF

1. Check the commutator contacting surface of each brush for

abnormal roughness. Also check the height of the brush.

Replace the brush holder if the height is lower than the limit.

Limit: 7.0 mm (0.27 in)

2. When the contact surface of the brush is rectified or the

brush holder is replaced, recondition the contact surface

with sandpaper wrapped around the commutator.

.

ARMATURE CHECK

AK304687

Overrunning

clutch

Stop ring

Snap ring

Stop ring

AF

1. Check that the armature coil is not grounded.

2. Place the armature in a growler.

3. Hold a thin steel blade parallel and just above the armature

while slowly rotating in the growler. A shorted armature will

cause a blade to vibrate and be attracted to the core.

Replace the shorted armature.