Mitsubishi Evolution X. Manual - part 205

AK600791

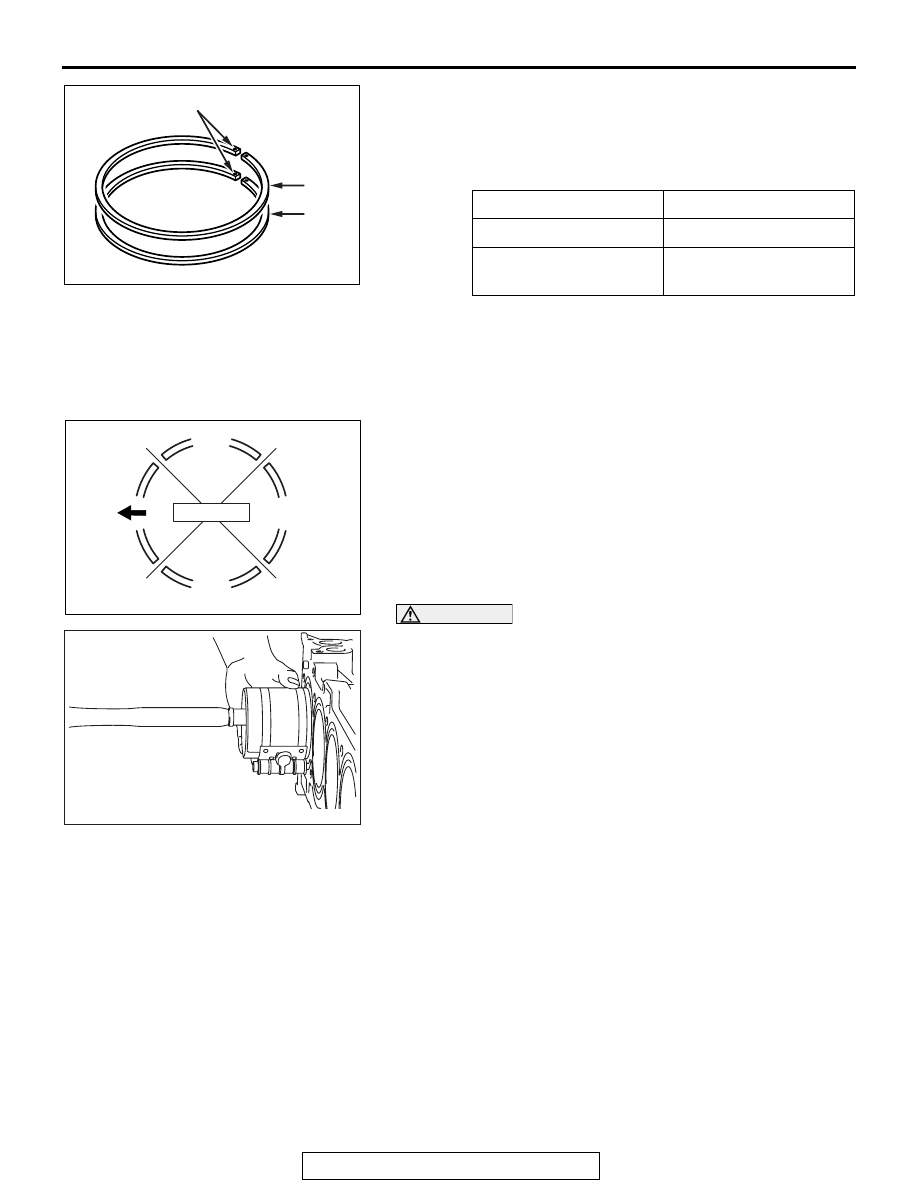

No. 2

No. 1

Identification mark

AC

PISTON AND CONNECTING ROD

TSB Revision

ENGINE OVERHAUL

11B-67

Identification mark

No. 1 ring: 1R

No. 2 ring: 2R

NOTE: Each of the available piston rings has a size mark as

follows:

Size

Size mark

Standard

No mark

0.25 mm (0.010 inch)

oversize

25

.

>>D<< PISTON CONNECTING ROD ASSEMBLY

INSTALLATION

1. Apply a sufficient amount of engine oil to the circumference

of the piston, piston rings and oil ring.

AK400403

No.1

Side rail

Side rail

AC

Piston pin

No.2

2. Arrange end gap positions of piston rings and oil ring (side

rail and spacer) as shown in the illustration.

3. Insert the piston and connecting rod assembly from the top

surface of the cylinder block with the front mark of the piston

top face facing toward the timing chain side.

AK502730

CAUTION

Driving it in hard causes breakage of piston rings and

damage to the crank pin.

4. Firmly tighten the piston ring with a ring band and insert the

piston and connecting rod assembly.

.