Mitsubishi Evolution X. Manual - part 198

TIMING CHAIN

TSB Revision

ENGINE OVERHAUL

11B-39

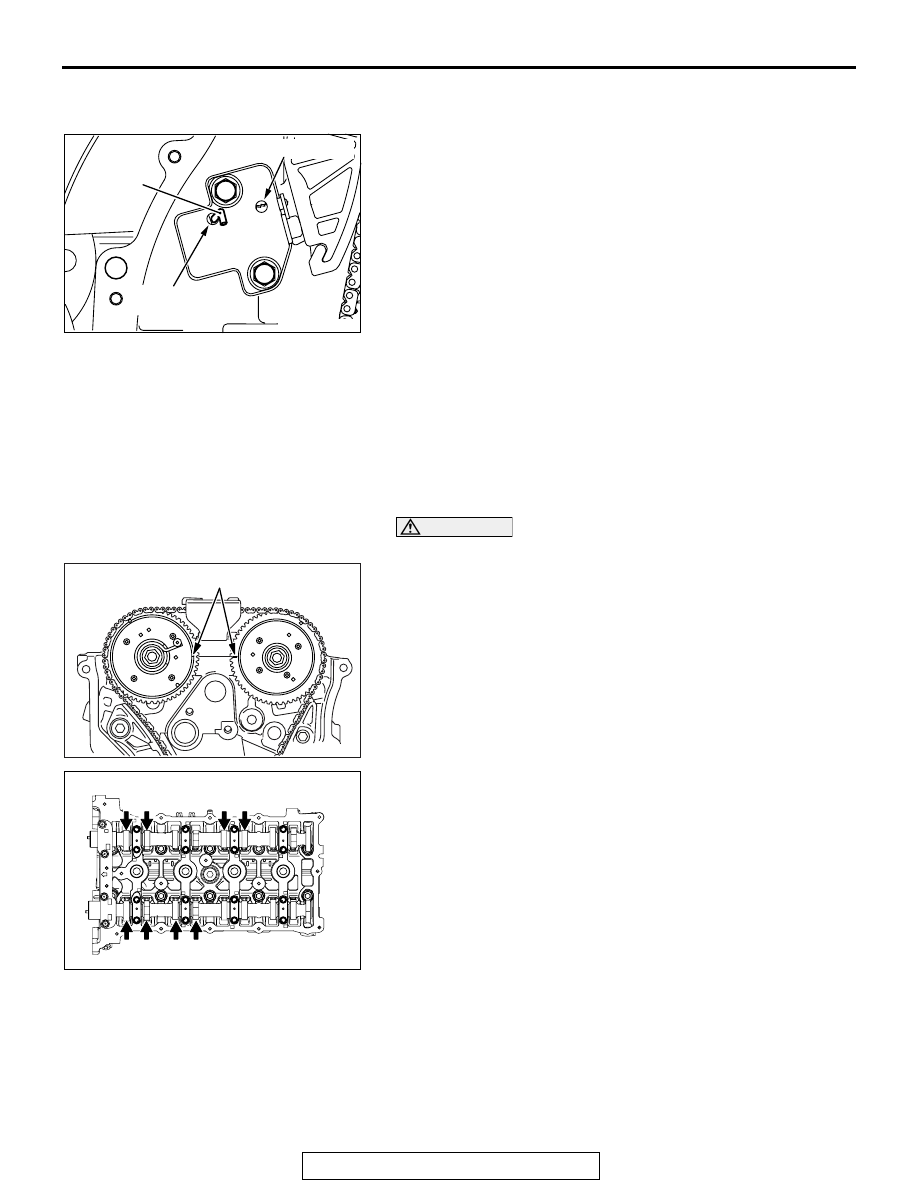

>>D<< TIMING CHAIN TENSIONER

INSTALLATION

AK502854 AG

Wire

Ratchet release hole

Plunger fixed

hole

1. Install the timing chain tensioner on the cylinder block and

tighten it to the specified torque.

Specified torque: 10

± 2 N⋅ m (89 ± 17 in-lb)

2. Remove the hard wire (piano wire or the like) of

φ1.5 or

hexagonal bar wrench (1.5 mm [0.05 inch]) from the timing

chain tensioner. This enables the plunger of the timing chain

tensioner to push the tensioner lever to keep the timing

chain tight.

INSPECTION

M1113026700462

.

VALVE CLEARANCE ADJUSTMENT

Measure valve clearance as described in the following proce-

dure.

Check and adjust the valve clearance with the timing chain

installed.

CAUTION

Always rotate the crankshaft clockwise.

AK502968AE

Timing mark

1. Rotate the crankshaft clockwise to align the timing mark of

the V.V.T. sprocket with the top surface of the cylinder head

as illustrated. (Set the No. 1 piston at top dead center on the

compression stroke.)

10

11

12

7

8

8

3

4

4

3

1

2

2

1

5

6

6

5

9

AK502387AG

Intake valve side

No.1

No.2

No.3

Exhaust valve side

No.1

2. Valve clearance can be measured at the illustrated location

in this condition.