Mitsubishi Evolution X. Manual - part 180

OIL PAN

TSB Revision

ENGINE MECHANICAL

11A-51

OIL PAN

REMOVAL AND INSTALLATION

M1112002801818

Required Special Tool:

• MD998727: Oil Pan FIPG Cutter

Pre-removal operation

• Engine Room Under Cover Front A, B, Engine Room

Under Cover Center and Engine Room Side Cover (RH)

Removal (Refer to GROUP 51, Under Cover

• Engine Oil Draining (Refer to GROUP 12, On-vehicle Ser-

vice

− Engine Oil Replacement

).

• Drive Belt Removal (Refer to

).

Post-installation operation

• Drive Belt Installation (Refer to

).

• Engine Oil Refilling (Refer to GROUP 12, On-vehicle Ser-

vice

− Engine Oil Replacement

).

• Engine Room Under Cover Front A, B, Engine Room

Under Cover Center and Engine Room Side Cover (RH)

Installation (Refer to GROUP 51, Under Cover

AC708918

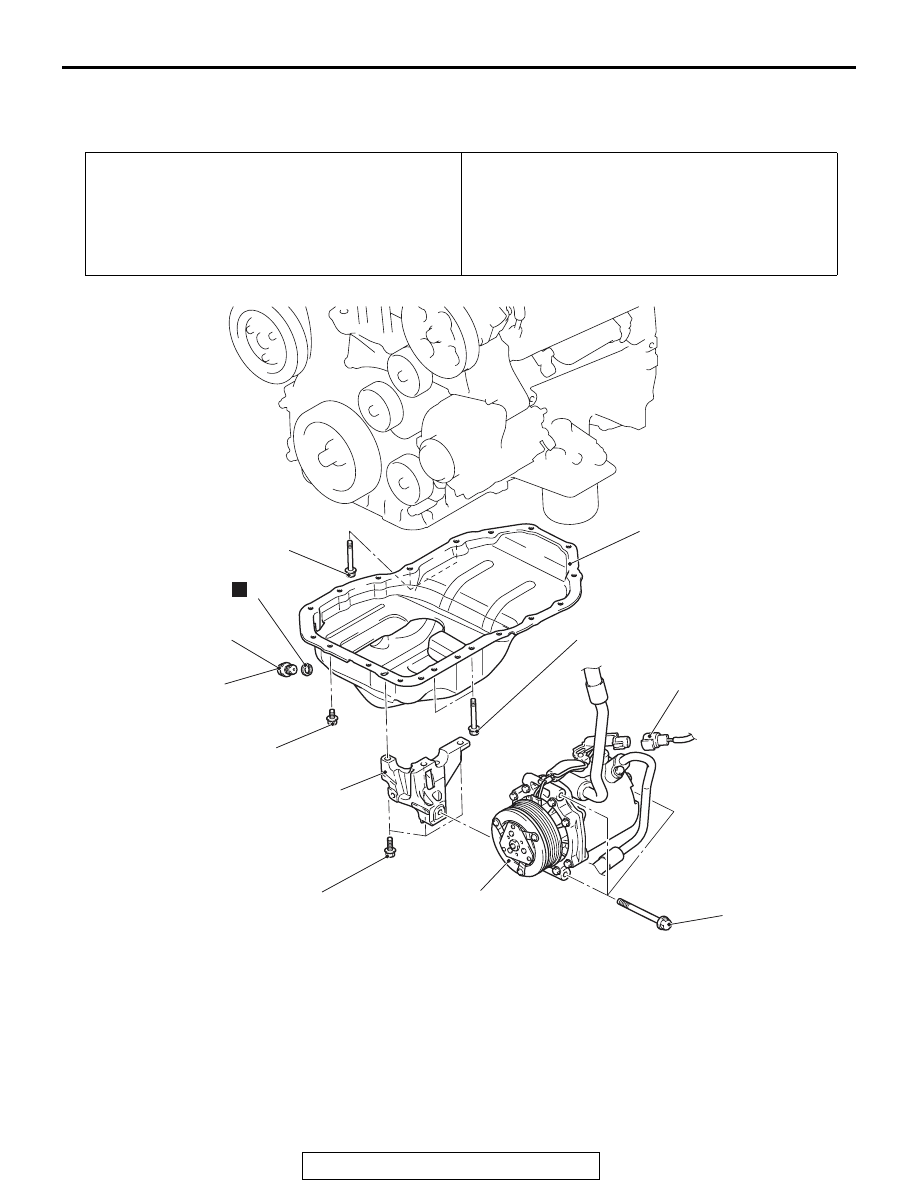

4

3

5

1

2

39 ± 5 N·m

29 ± 3 ft-lb

10 ± 2 N·m

89 ± 17 in-lb

29 ± 2 N·m

22 ± 1 ft-lb

23 ± 6 N·m

17 ± 4 ft-lb

23 ± 6 N·m

17 ± 4 ft-lb

N

AB

6

29 ± 2 N·m

22 ± 1 ft-lb

Removal steps

1.

A/C compressor assembly

connector connection

<<

A

>>

>>

C

<<

2.

A/C compressor and clutch

assembly

3.

A/C compressor bracket

4.

Engine oil pan drain plug

>>

B

5.

Engine oil pan drain plug gasket

<<

B

>>

>>

A

6.

Engine oil pan

Removal steps (Continued)