Mitsubishi Evolution X. Manual - part 151

TRANSAXLE CONTROL

TSB Revision

TWIN CLUTCH-SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22B-17

TRANSAXLE CONTROL

GENERAL INFORMATION

M2222000100383

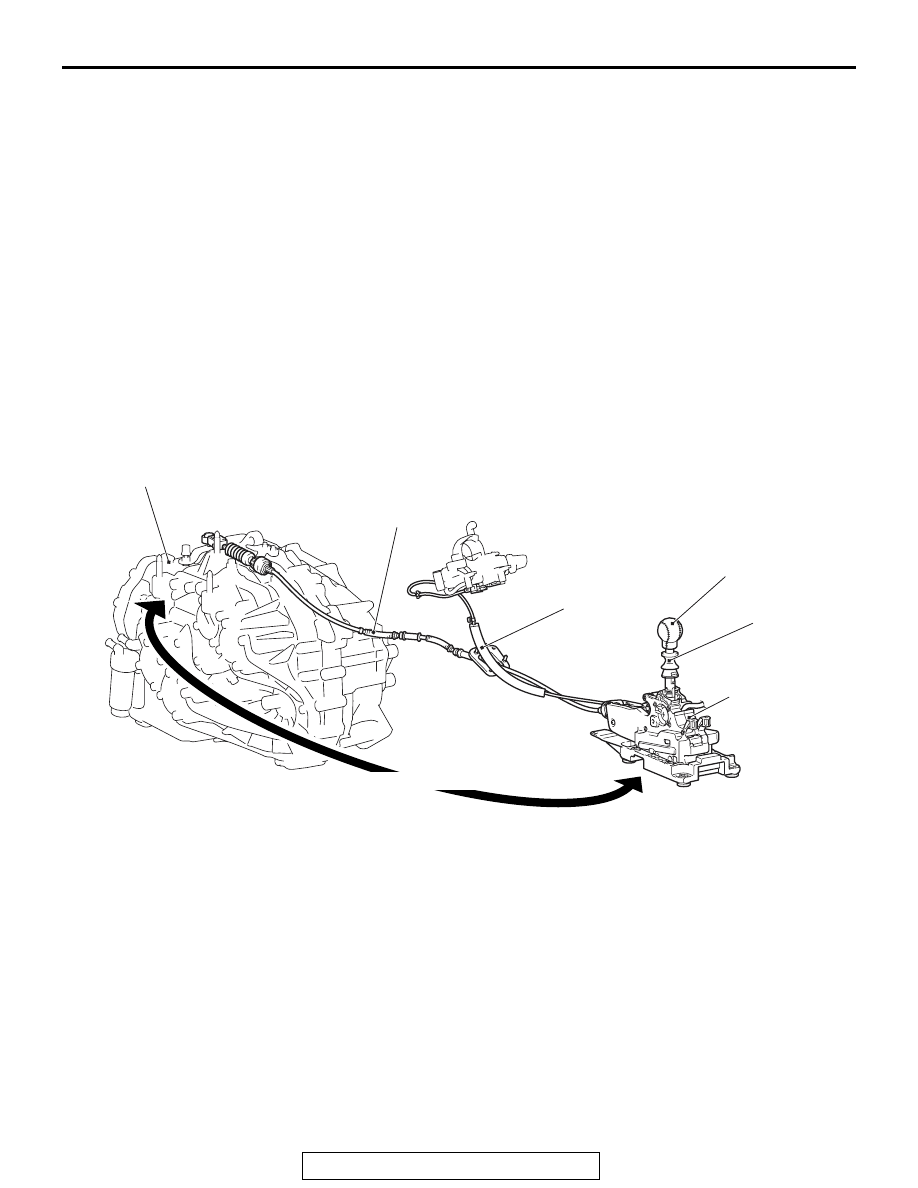

In order to differentiate the TC-SST assembly shift

lever from A/T and CVT, a new exclusive shift lever

has been developed whose appearance is made

similar to that for M/T. It offers the following features.

• Sporty, straight type shift lever operation has

been adopted, and the operating power at each

shift position have been properly tuned, ensuring

the firm and smooth operation feel.

• The manual mode (6-speed) has been installed

to allow manual shifting according to the driver's

operation.

• ECU that is incorporated in the shift lever trans-

mits the lever position information and others to

TC-SST-ECU via CAN (main circuit) and LIN

(auxiliary circuit).

• For the parking lock mechanism, the transaxle

control cable is adopted.

• The electrical control-type shift lock (shift lever

cannot be shifted to the position other than P

position unless the brake pedal is depressed)

mechanism with the solenoid has been adopted

to facilitate the tuning work in assembly. The

cable type having an established past record is

adopted for the key interlock mechanism.

• Spherical shift knob is used to achieve the same

quality as that for M/T.

• As a mis-operation preventative mechanism

between P and R range, the pull ring has been

adopted.

• The main components have been made of resin

to reduce weight and number of components.

ERRONEOUS OPERATION PREVENTION MECHANISMS

M2222004000021

SHIFT LOCK MECHANISM

This is basically the same as with the electric shift

lock mechanism which is used for OUTLANDER.

KEY INTERLOCK MECHANISM

This is basically the same as with the cable-type key

interlock mechanism which is used for A/T vehicles.

AC705528

AC709661

Shift knob

Shift lever assembly

(Incorporates shift lock

solenoid and ECU)

Transaxle assembly

Key interlock cable

Transaxle control

cable assembly

AB

CAN and LIN communication

Pull-ring