Content .. 1114 1115 1116 1117 ..

Mitsubishi Evolution X. Manual - part 1116

DIAGNOSIS

TSB Revision

CONTROLLER AREA NETWORK (CAN)

54C-99

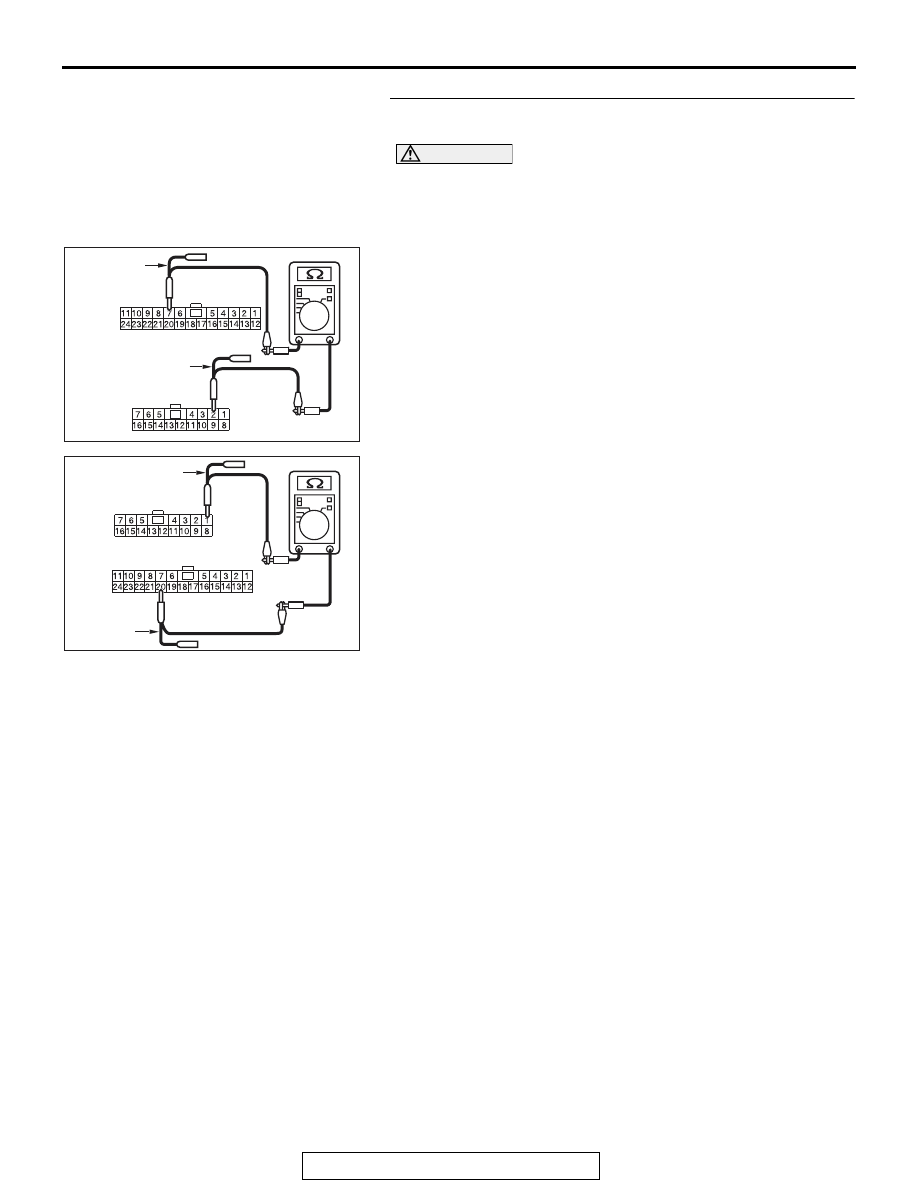

STEP 2. Check the wiring harness between joint connector

(CAN3) C-127 and shift lever connector C-27.

CAUTION

Strictly observe the specified wiring harness repair proce-

dure. For details refer to

(1) Disconnect joint connector (CAN3) C-127 and shift lever

connector C-27, and check the wiring harness.

(2) Check the wiring harness between joint connector (CAN3)

C-127 (terminal 7) and shift lever connector C-27 (terminal

2)

OK: Continuity exists (2

Ω or less)

(3) Check the wiring harness between joint connector (CAN3)

C-127 (terminal 20) and shift lever connector C-27 (terminal

1)

OK: Continuity exists (2

Ω or less)

Q: Is the wiring harness between joint connector (CAN3)

C-127 and shift lever connector C-27 in good condition?

YES : Check the power supply circuit of the shift lever. Refer

<shift

lever>.

NO : Repair the wiring harness between joint connector

(CAN3) C-127 and shift lever connector C-27.

AC709707

Harness side: C-127

BL

Harness side: C-27

TEST

HARNESS

TEST HARNESS

AC709707

Harness side: C-127

BM

Harness side: C-27

TEST HARNESS

TEST

HARNESS