Content .. 1019 1020 1021 1022 ..

Mitsubishi Evolution X. Manual - part 1021

MMCS

TSB Revision

CHASSIS ELECTRICAL

54A-445

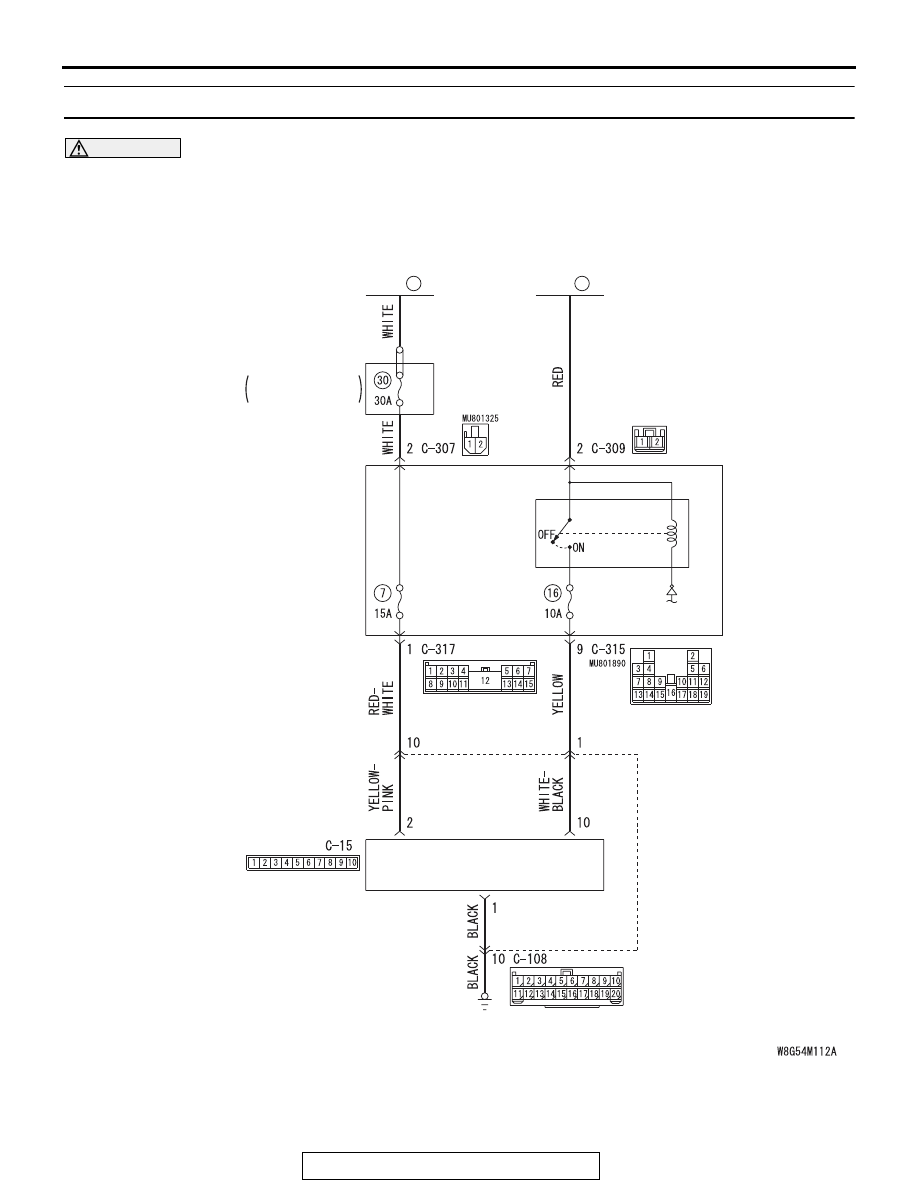

Inspection Procedure 12: Check the CAN box unit power supply circuit.

CAUTION

Before replacing the ECU, ensure that the power supply circuit, the ground circuit and the communi-

cation circuit are normal. (Check that the voltage is 10 V or more.)

CAN Box Unit Power Supply Circuit

ACC

RELAY 2

ETACS-

ECU

FUSIBLE

LINK

36

FUSIBLE

LINK

37

CAN BOX UNIT

RELAY BOX

ENGINE

COMPARTMENT