Mitsubishi Evolution X. Manual - part 52

BASE ENGINE

TSB Revision

ENGINE

11-6

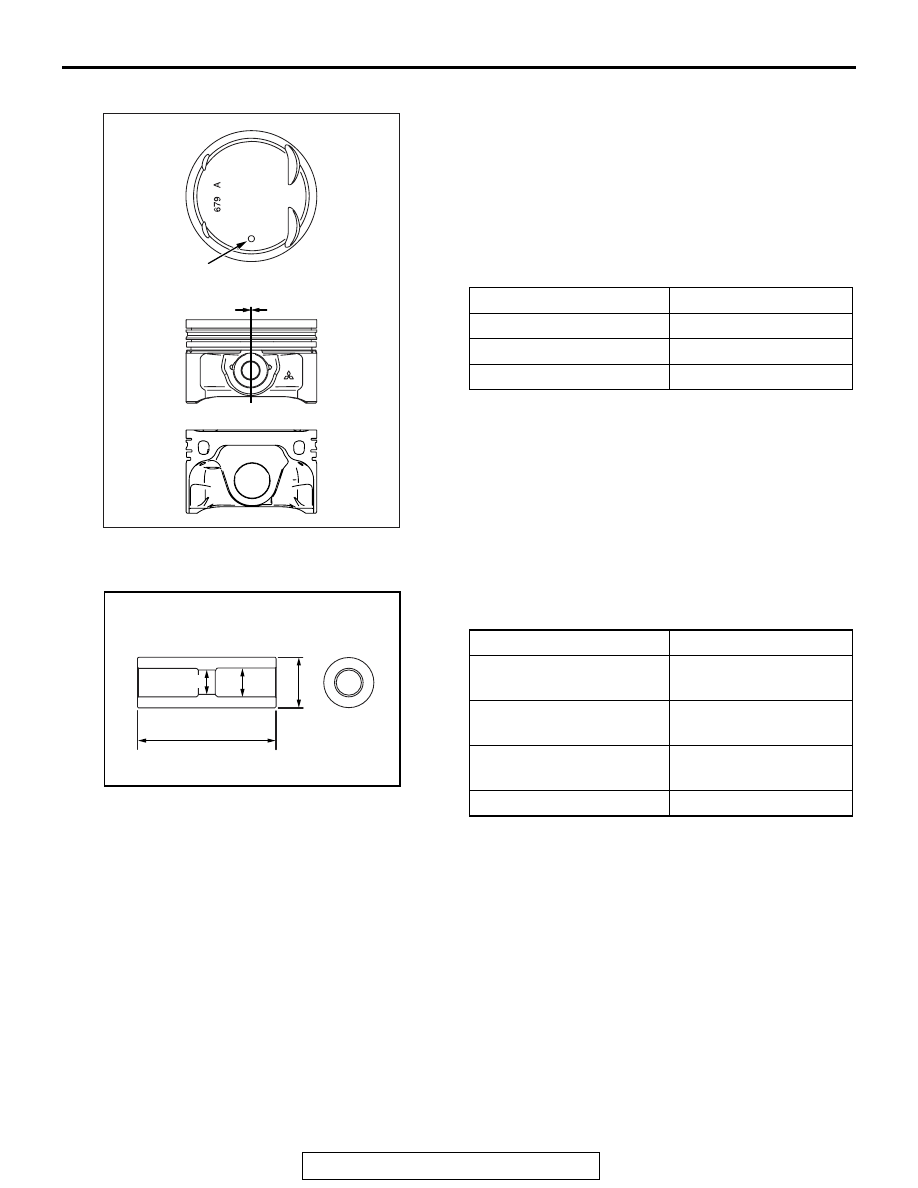

PISTONS

The pistons are made of a special aluminum alloy.

Their weight has been reduced by lowering their

overall height and increasing the depression at each

end of the piston pin.

The piston pin hole center is offset 0.5 mm (0.020 in)

towards the thrust side of the piston center.

The skirt portion along the perimeter of the piston is

finished with streaks that excel in oil retention and

seizure resistance.

PISTON PINS

The full floating type of piston is used to improve the

reliability by reducing the friction.

AK703206AC

Front mark

Piston offset

ITEM

SPECIFICATIONS

Basic diameter mm (in)

86 (3.4)

Pin hole diameter mm (in) 23 (0.9)

Overall height mm (in)

54.87 (2.160)

AK703727

d2

AC

D

h

d1

ITEM

SPECIFICATIONS

Outer diameter (D) mm

(in)

23 (0.9)

Inner diameter (d1) mm

(in)

11.5 (0.45)

Inner diameter (d2) mm

(in)

10.5 (0.41)

Overall length (h) mm (in) 60 (2.4)