Mitsubishi Lancer Evolution X. Manual - part 628

INPUT SHAFT

TSB Revision

MANUAL TRANSAXLE OVERHAUL

22B-25

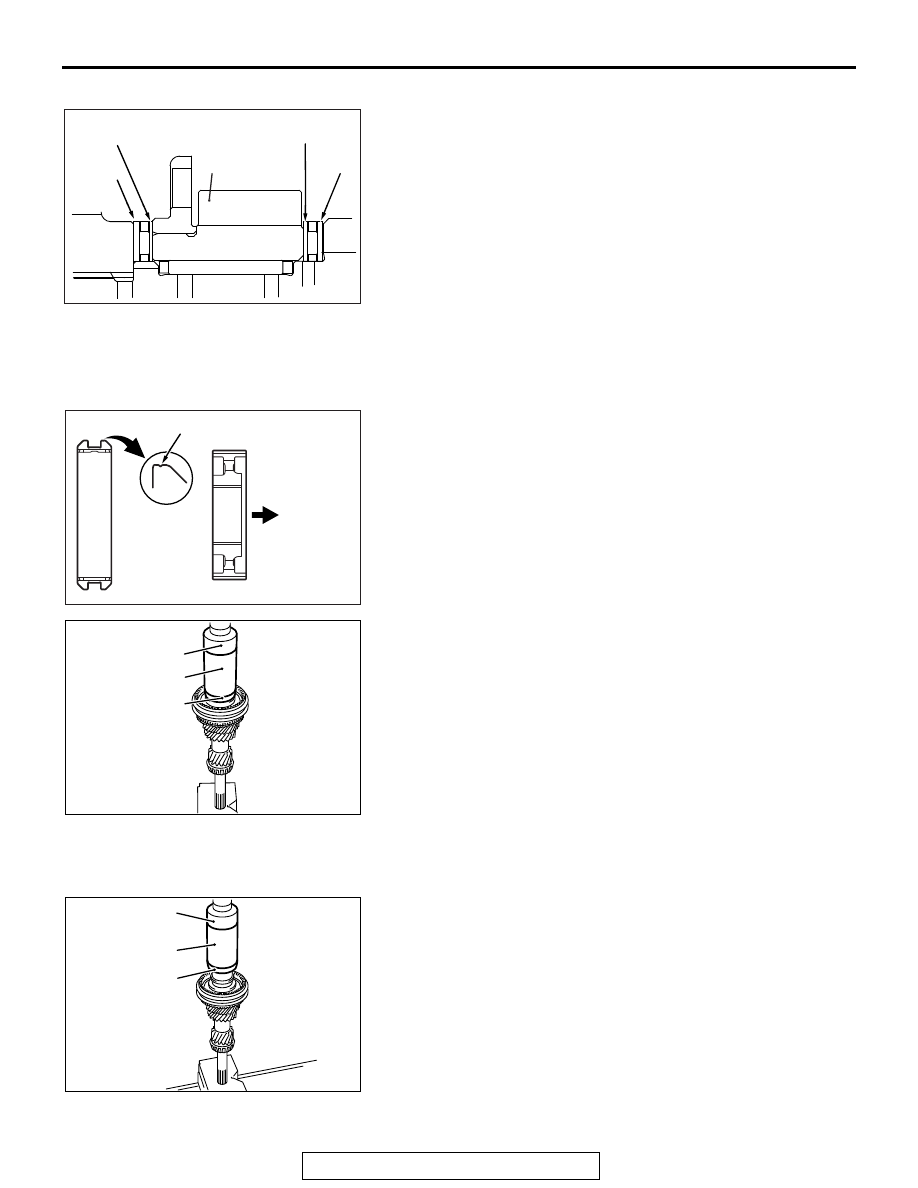

>>B<< THRUST BEARING INSTALLATION

Install the thrust bearings as shown.

.

>>C<< 3RD-4TH SPEED SYNCHRONIZER HUB /

3RD-4TH SPEED SYNCHRONIZER SLEEVE

INSTALLATION

1. Install the 3rd-4th speed synchronizer hub and synchronizer

sleeve in the illustrated direction.

2. Using the special tools, MD998812, MD998813 and

MD998822, indicated below, install the 3rd-4th speed

synchronizer sleeve, 3rd-4th speed synchronizer hub,

synchronizer outer ring, synchronizer inner ring and

synchronizer cone.

3. After installation, check that the 3rd speed gear rotates

smoothly.

.

>>D<< 4TH SPEED GEAR SLEEVE

INSTALLATION

Using the special tools, MD998812, MD998813 and

MD998822, indicated below, install the 4th speed gear sleeve.

.

AK703374AC

(thick)

3rd speed gear

(thin)

Black

Colorless

(thin)

Colorless

(thick)

Black

AK703159

Identification groove

Installation

direction

AC

AK703169

AC

MD998812

MD998813

MD998822

AK703170

AC

MD998812

MD998813

MD998822