Mitsubishi Lancer Evolution X. Manual - part 602

DIAGNOSIS <TC-SST>

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-365

SPECIAL FUNCTION

M1225028400052

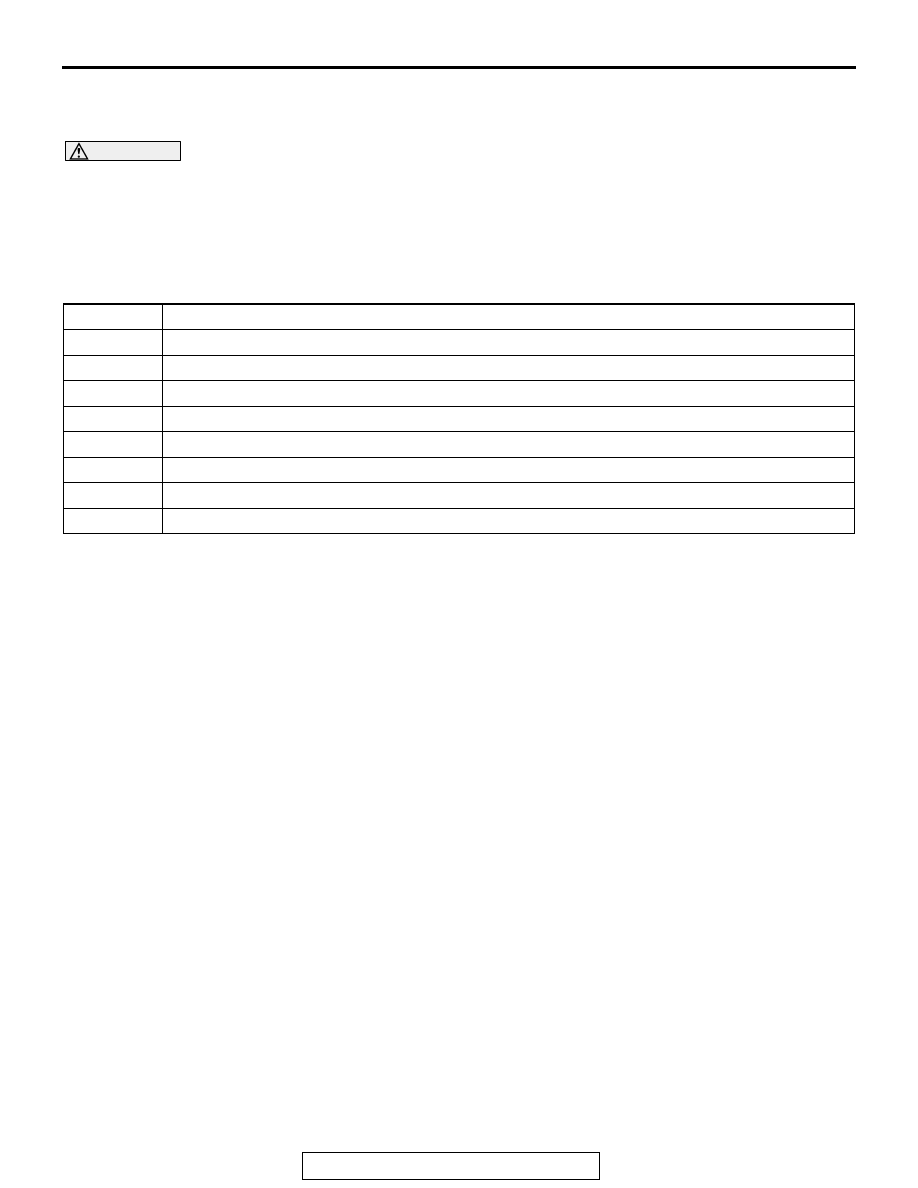

TEACH-IN REFERENCE TABLE

CAUTION

Be careful with the following items when performing Item No.3: Line Pressure Test.

• The engine speed could be high (4,000 r/min) when the Line Pressure Test is in progress. (Depend-

ing on the transaxle state, the engine speed may not be high.)

• After Teach-In completion, check that it completed normally. (Teach-In execution results is dis-

played in the following Data list.)

TEACH-IN

NOTE:

.

•

According to the transmission fluid state (fluid -filled state), Teach-In executed time is not equal.

•

Item No.8 is not displayed when the Diag. Version of TC-SST-ECU is pre-0002. (Diag. Version can be

checked by the Teach-In screen of scan tool.)

Item No.

Scan tool Item Name

1

Plausibility check

2

Shift fork Teach-In

3

Line pressure Test

4

Stroke Teach-In

5

Boost Teach-In

6

Interlock Teach-In

7

Clutch Ventilation

8

Reset clutch gain