Mitsubishi Lancer Evolution X. Manual - part 574

DIAGNOSIS <TC-SST>

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-253

• P2728: Clutch/shift pressure solenoid 2 system

(Overcurrent)

• P2729: Clutch/shift pressure solenoid 2 system

(Short to ground)

• P2730: Clutch/shift pressure solenoid 2 system

(Short to power supply)

• P2809: Clutch/shift switching solenoid 2, spool

stuck

• P2812: Clutch/shift switching solenoid 2 system

(Open circuit)

• P2814: Clutch/shift switching solenoid 2 system

(Short to ground)

• P2815: Clutch/shift switching solenoid 2 system

(Short to power supply)

• P181B: Clutch 1 (Pressure low range out)

• P181C: Clutch 1 (Pressure high range out)

• P181E: Clutch 2 (Pressure low range out)

• P181F: Clutch 2 (Pressure high range out)

Sensor (The sensor below is determined to be

normal)

• Shift select solenoid 1

• Clutch/shift pressure solenoid 2

• Clutch/shift switching solenoid 2

.

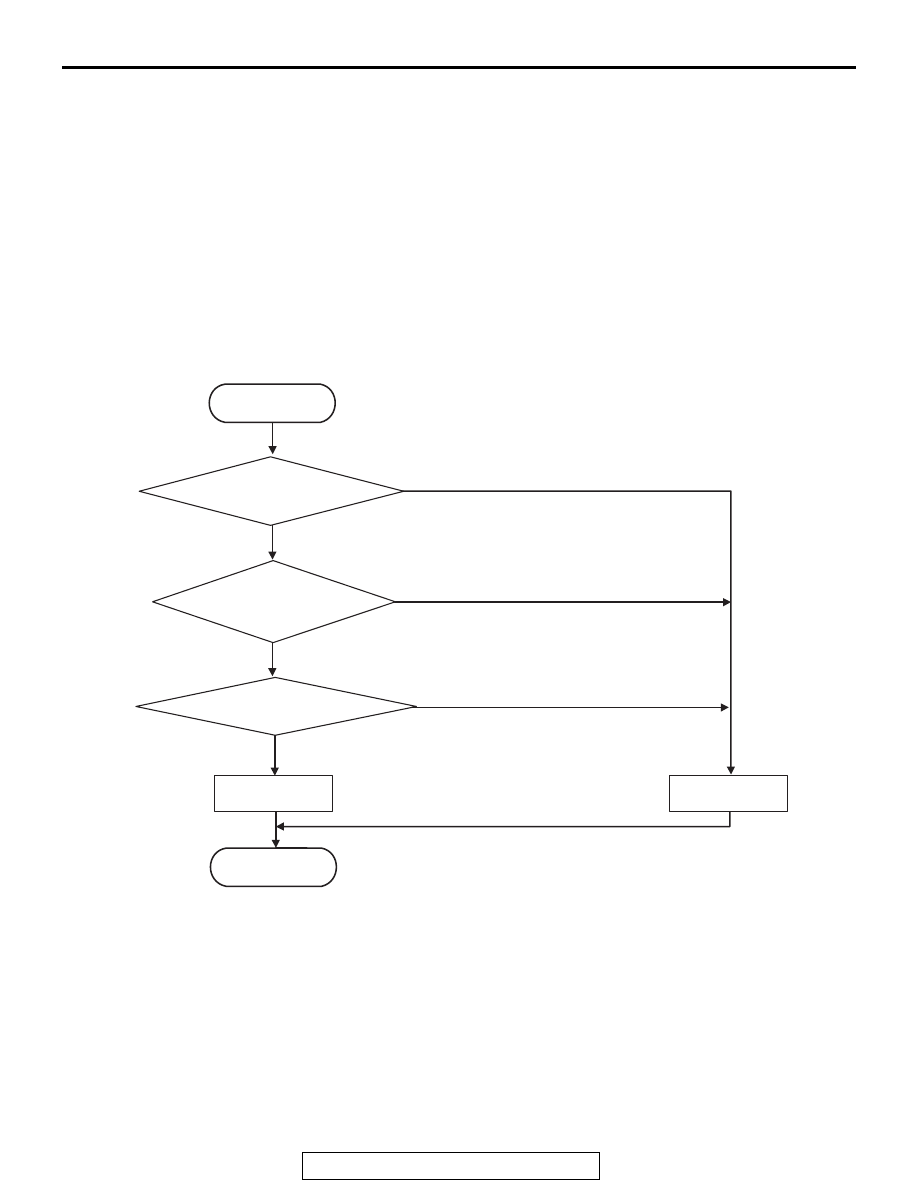

LOGIC FLOW CHARTS (Monitor Sequence)

.

DTC SET CONDITIONS

Check Conditions

• Voltage of battery: 8 V or more.

• Voltage of battery: 16.5 V or less.

• Engine speed: 650 r/min or more.

• Time since above engine condition: 1.5 seconds

or more.

• FET (Field Effect Transistor) of high side 3:

Switched off.

JUDGMENT CRITERIA

• FET output: 100 mV or less. (5 seconds)

.

OBD-II DRIVE CYCLE PATTERN

The FET channel output remains 100 mV or more for

5 seconds.

.

PROBABLE CAUSES

• Malfunction of TC-SST-ECU

• Malfunction of power supply circuit (open circuit)

AC710728

START

No

Good

Malfunction

END

Continuous failure

for 5 sec

No

Yes

Yes

Monitoring condition met

Yes

No

FET* output < 100 mV

*FET : Field Effect Transistor