Mitsubishi Lancer Evolution X. Manual - part 546

DIAGNOSIS <TC-SST>

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-141

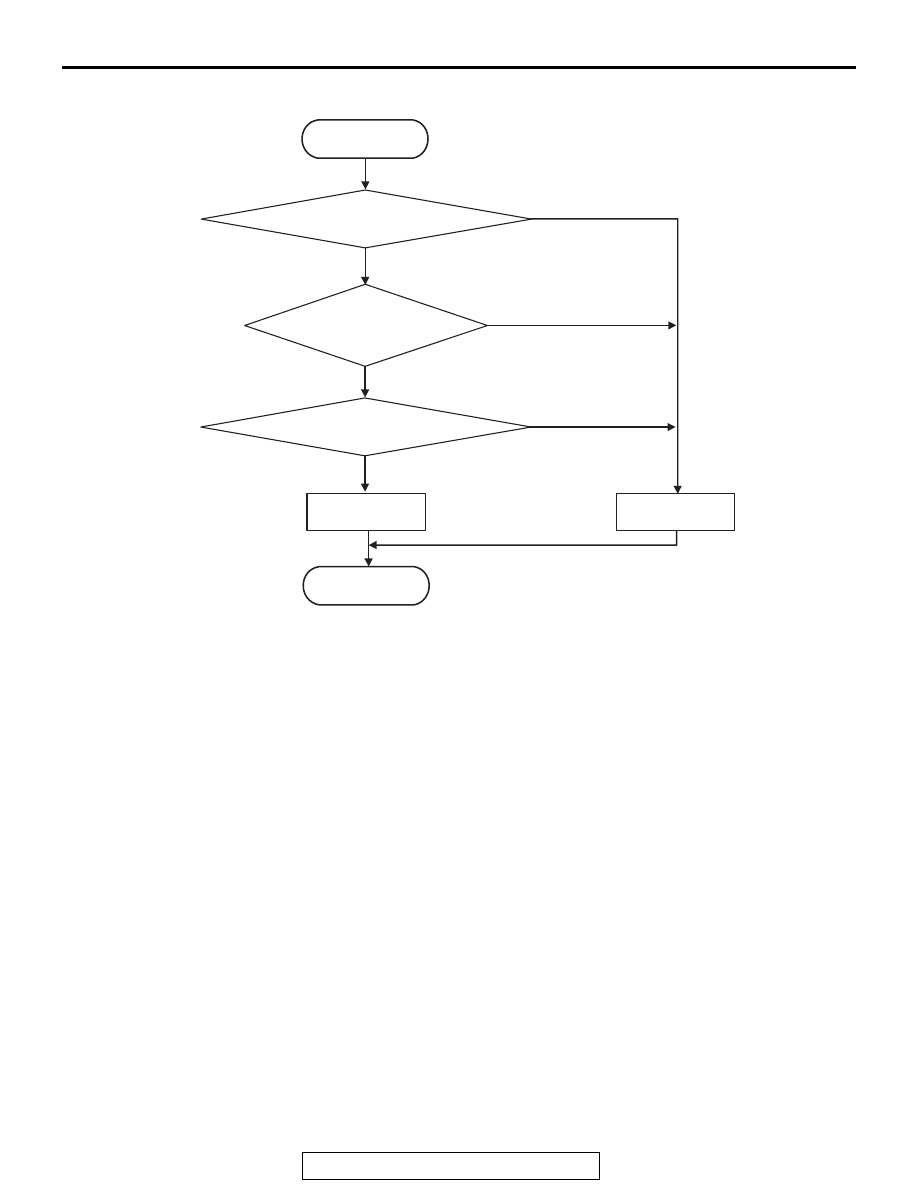

LOGIC FLOW CHARTS (Monitor Sequence)

.

DTC SET CONDITIONS

Check Conditions

• Voltage of battery: 8 V or more.

• Voltage of battery: 16.5 V or less.

• Engine speed: 650 r/min or more.

• Time since above engine condition: 1.5 seconds

or more.

• Input shaft 1 (odd) speed: 500 r/min or more.

• Input shaft 2 (even) speed: 500 r/min or more.

• Shift fork 1 position: Neutral.

• Input shaft 2 (even) gear: Engaged.

• Engine speed − input shaft 2 speed: 50 r/min or

less.

JUDGMENT CRITERIA

• Calculated speed: 40 r/min or less. (500 millisec-

ond)

.

OBD-II DRIVE CYCLE PATTERN

The calculated speed remains 40 r/min or more for

500 millisecond.

.

PROBABLE CAUSES

• Malfunction of TC-SST-ECU

• Malfunction of shift fork position sensor 1

DIAGNOSTIC PROCEDURE

Required Special Tools:

• MB991958 Scan Tool (M.U.T.-III Sub Assembly)

• MB991824: Vehicle Communication Interface (V.C.I.)

• MB991827 M.U.T.-III USB Cable

• MB991910 M.U.T.-III Main Harness A

AC711383

START

No

Good

Malfunction

END

Monitoring condition met

Continuous failure

for 500 msec

No

Yes

Yes

Yes

No

Calculated input

shaft speed

AC

Calculated input shaft

speed <= 40 r/min