Mitsubishi Lancer Evolution X. Manual - part 534

DIAGNOSIS <TC-SST>

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-93

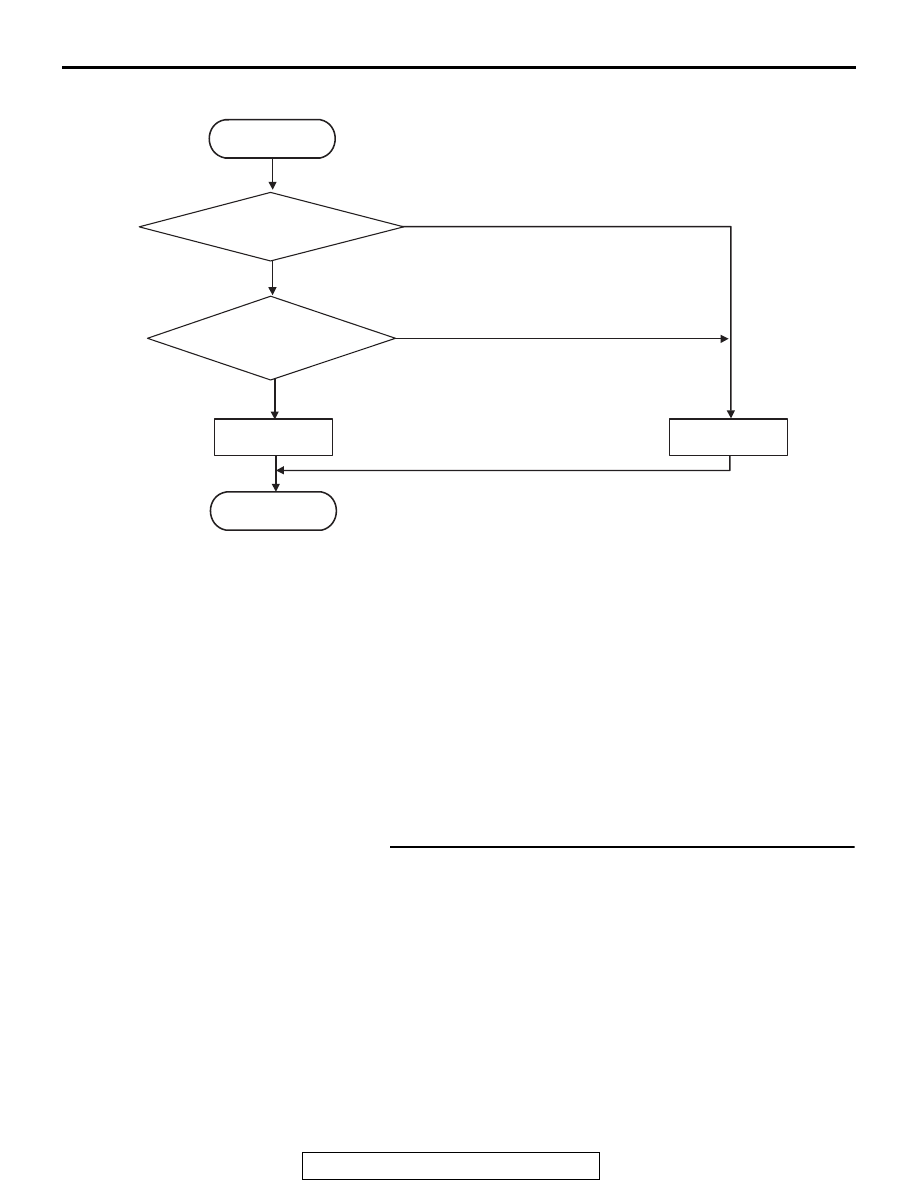

LOGIC FLOW CHARTS (Monitor Sequence)

.

DTC SET CONDITIONS

Check Conditions

• Ignition switch: ON

JUDGMENT CRITERIA

• Coding state: Not programmed. (Immediately)

.

OBD-II DRIVE CYCLE PATTERN

The coding is completed.

.

PROBABLE CAUSES

• Malfunction of TC-SST-ECU

DIAGNOSTIC PROCEDURE

Required Special Tools:

• MB991958 Scan Tool (M.U.T.-III Sub Assembly)

• MB991824: Vehicle Communication Interface (V.C.I.)

• MB991827 M.U.T.-III USB Cable

• MB991910 M.U.T.-III Main Harness A

STEP 1. Scan tool CAN bus diagnostics

Using scan tool MB991958, diagnose the CAN bus lines.

Q: Is the check result normal?

YES : Go to Step 2.

NO : Repair the CAN bus lines. (Refer to GROUP 54C −

Troubleshooting

.) After repairing the CAN

bus line, go to Step 2.

AC710730

START

No

Good

Malfunction

END

Yes

Yes

Monitoring condition met

No

Coding state =

not programmed