Mitsubishi Lancer Evolution X. Manual - part 453

ON-VEHICLE SERVICE

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-877

7. While repeatedly revving the engine, measure the heated

oxygen sensor output voltage.

Standard value:

CAUTION

• Be very careful when connecting the jumper wire;

incorrect connection can damage the oxygen sensor.

• Be careful the heater is broken when voltage of beyond

8V is applied to the oxygen sensor heater.

NOTE: If the temperature of sensing area does not reach

the high temperature [of approximately 400

°

C (752

°

F) or

more] even though the oxygen sensor is normal, the output

voltage would be possibly low in spite of the rich air-fuel

ratio. Therefore, if the output voltage is low, use a jumper

wire to connect terminal No. 1 and terminal No. 2 of the oxy-

gen sensor with a (+) terminal and (

−

) terminal of 8 V power

supply respectively, then check again.

8. If the output voltage is not within the standard value, replace

the heated oxygen sensor.

NOTE: For removal and installation of the heated oxygen

sensor, refer to GROUP 15, Exhaust Pipe and Main Muffler

−

Removal and installation

.

.

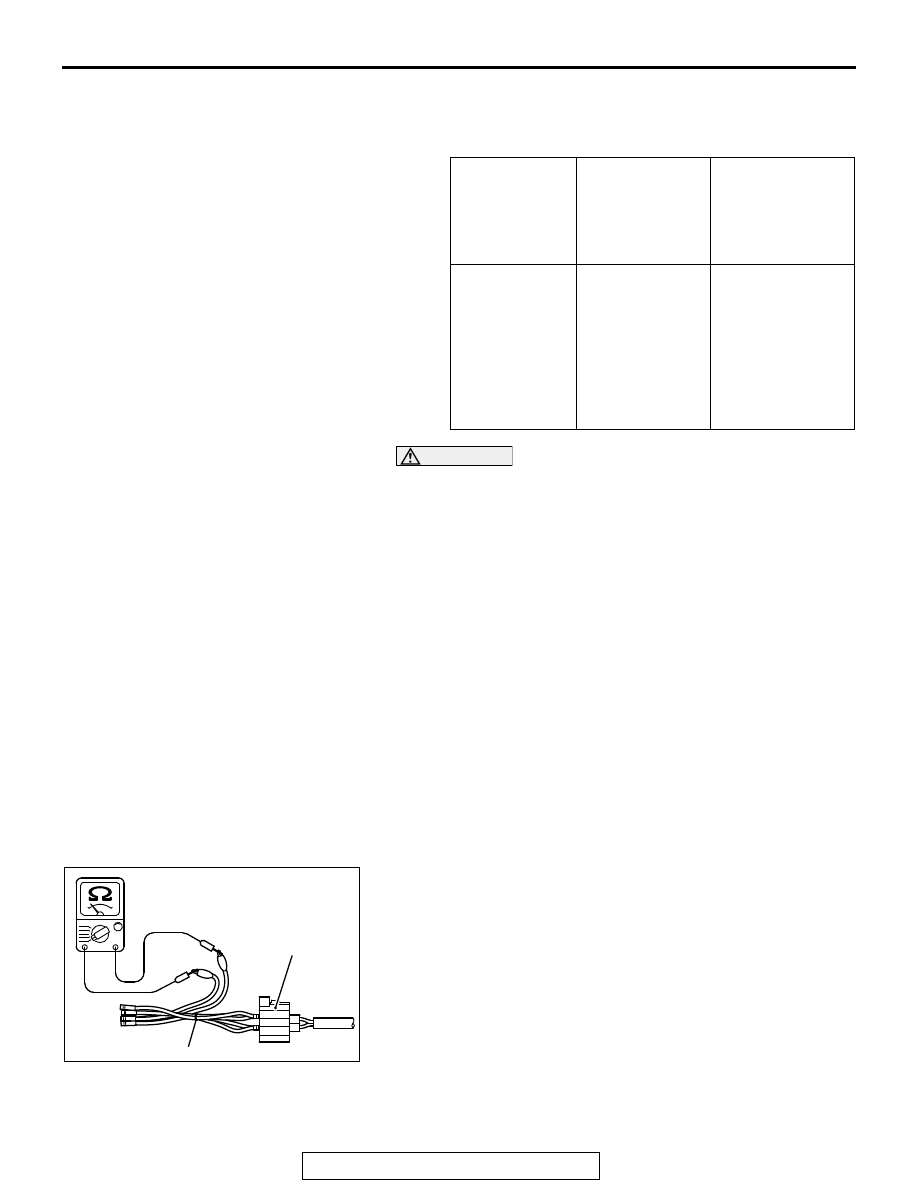

Heated oxygen sensor (rear)

1. Disconnect the heated oxygen sensor connector and

connect special tool MB991658 to the connector on the

heated oxygen sensor side.

2. Measure the resistance between terminal No. 1 and terminal

No. 2 on the heated oxygen sensor connector.

Standard value: 4.5 − 8.0 Ω [at 20 ° C (68 ° F)]

3. If the resistance deviates from standard value, replace the

heated oxygen sensor.

4. Warm up the engine until engine coolant is 80° C (176° F) or

higher.

5. Drive at 50 km/h (31 mph) or more for 10 minutes.

ENGINE

HEATED

OXYGEN

SENSOR

OUTPUT

VOLTAGE

REMARKS

When revving

engine

0.6 − 1.0 V

If you make the

air/fuel ratio rich

by revving the

engine repeatedly,

a normal heated

oxygen sensor will

output a voltage of

0.6 − 1.0 V.

AK604492AB

MB991658

Heated oxygen

sensor component

side connector