Mitsubishi Lancer Evolution X. Manual - part 404

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-681

STEP 1. Test the OBD-II drive cycle.

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Carry out the test drive with the drive cycle pattern. Refer to

Diagnostic Function OBD-II Drive Cycle − Pattern 23

(4) Check the diagnostic trouble code (DTC).

Q: Is DTC P2253 set?

YES : Replace the ECM. When the ECM is replaced,

register the ID code. Refer to GROUP 42B, ID Code

Registration Necessity Judgment Table <Vehicles

with KOS>

or GROUP 42C, ID Codes

Registration Judgment Table <Vehicles with WCM>

NO : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points − How to

Cope with Intermittent Malfunctions

.

DTC P2263: Intake Charge System Malfunction

.

TECHNICAL DESCRIPTION

• The ECM indicates or monitors a minimum pre-

scribed value of volumetric efficiency within the

boost operation range, which is determined by

the signals from the throttle position sensor and

the engine speed.

.

DTC SET CONDITIONS

Check Conditions

• Engine speed is between 3,000 and 5,000 r/min.

• Throttle position sensor (main) output voltage is

higher than 2 volts.

Judgment Criterion

• Volumetric efficiency is lower than 100 percent for

2 seconds.

.

FAIL-SAFE AND BACKUP FUNCTION

• Fuel is cut in engine overboost condition.

.

TROUBLESHOOTING HINTS (The most

likely causes for this code to be set are:)

• Turbocharger wastegate actuator failed.

• Turbocharger wastegate regulating valve failed.

• Charging pressure control system failed.

• Intake charge pressure leak.

• ECM failed.

DIAGNOSIS

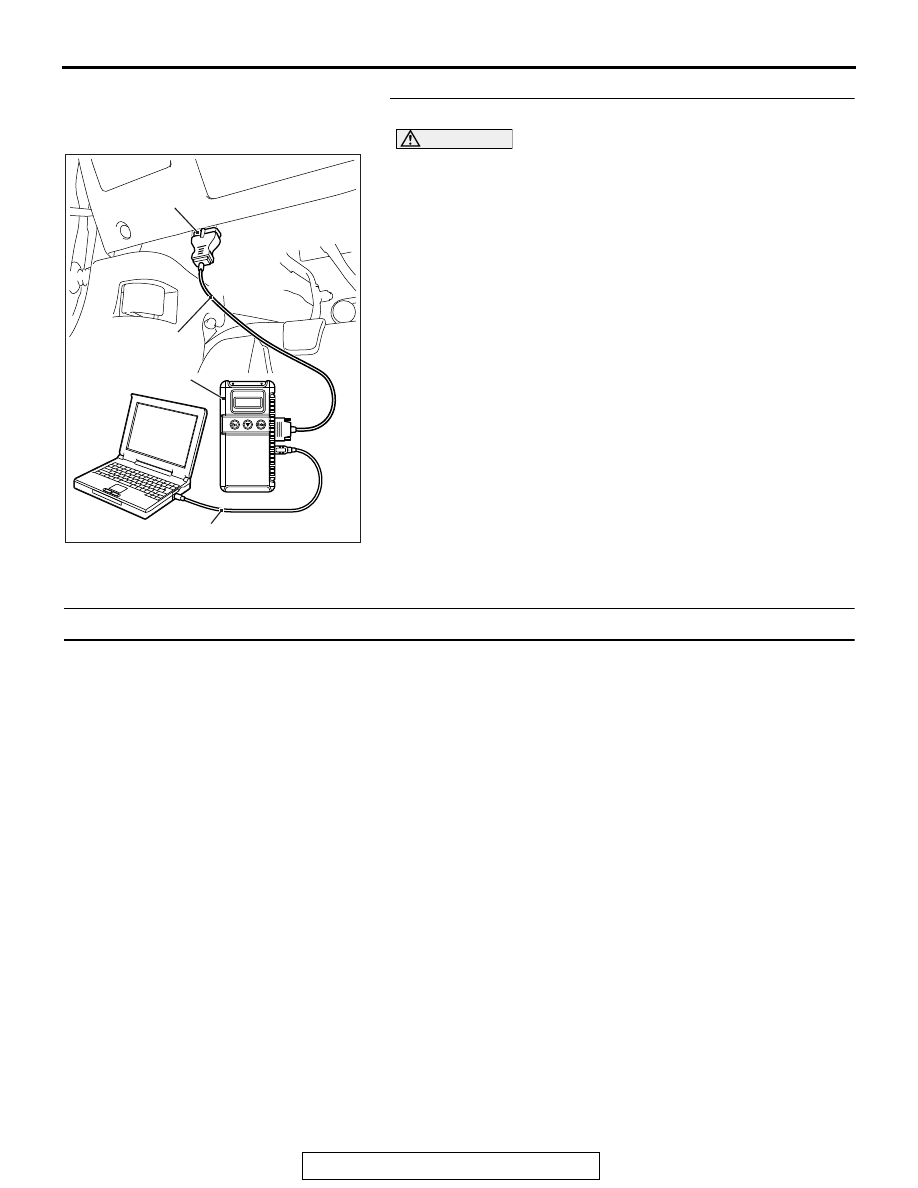

Required Special Tools:

• MB991958: Scan Tool (M.U.T.-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: USB Cable

• MB991910: Main Harness A

AC608435

Data link connector

MB991827

MB991824

MB991910

AB