Mitsubishi Lancer Evolution X. Manual - part 356

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-489

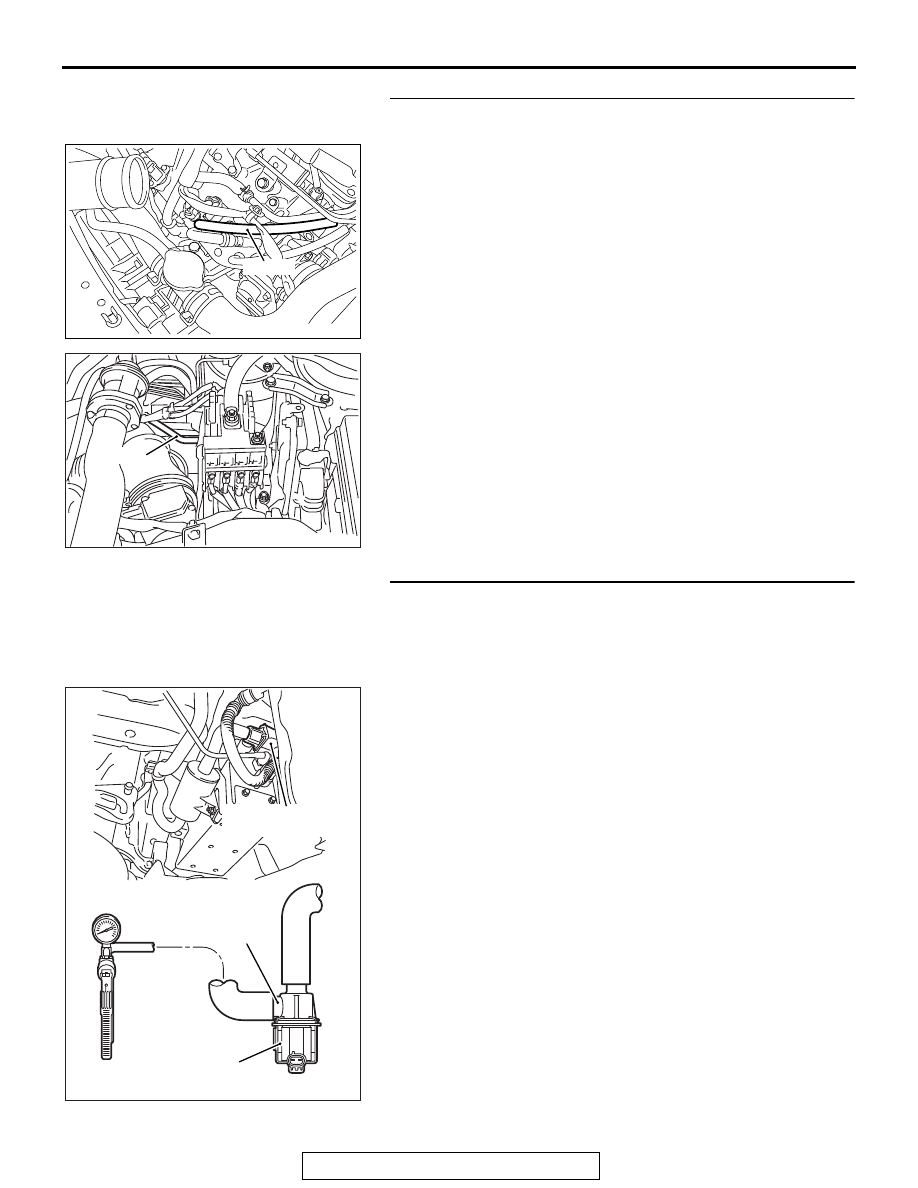

STEP 5. Check for leaks in evaporative emission hoses C

and D.

Use a hand vacuum pump to test each hose C and D.

Q: Do the hoses hold vacuum?

YES : Go to Step 6 .

NO : Replace any damaged hose. Then go to Step 14 .

STEP 6. Using scan tool MB991958, check actuator test

item 15: Evaporative emission ventilation solenoid.

(1) Remove the canister cover.

(2) Remove the evaporative emission ventilation solenoid. Do

not disconnect the connector.

(3) Connect the hose of the hand vacuum pump to the canister

side nipple of the evaporative emission ventilation solenoid.

(4) Turn the ignition switch to the "ON" position.

(5) Set scan tool MB991958 to actuator test mode.

• Item 15: Evaporative Emission Ventilation Solenoid.

• While the evaporative emission ventilation solenoid

is energized, operate the hand vacuum pump and

confirm that the solenoid holds vacuum.

(6) Turn the ignition switch to the "LOCK" (OFF) position.

(7) Disconnect the hand vacuum pump, and reinstall the

evaporative emission ventilation solenoid.

(8) Reinstall the canister cover.

Q: Did the evaporative emission ventilation solenoid hold

vacuum?

YES : Go to Step 7 .

NO : Replace the evaporative emission ventilation

solenoid. Then go to Step 14 .

AK704689

Hose C

AB

AK704690 AB

Hose D

AK704699 AB

Evaporative emission

ventilation solenoid

Canister

side nipple

Evaporative emission

ventilation solenoid