Mitsubishi Lancer Evolution X. Manual - part 200

DIAGNOSIS

TSB Revision

ACTIVE STABILITY CONTROL SYSTEM (ASC)

35C-265

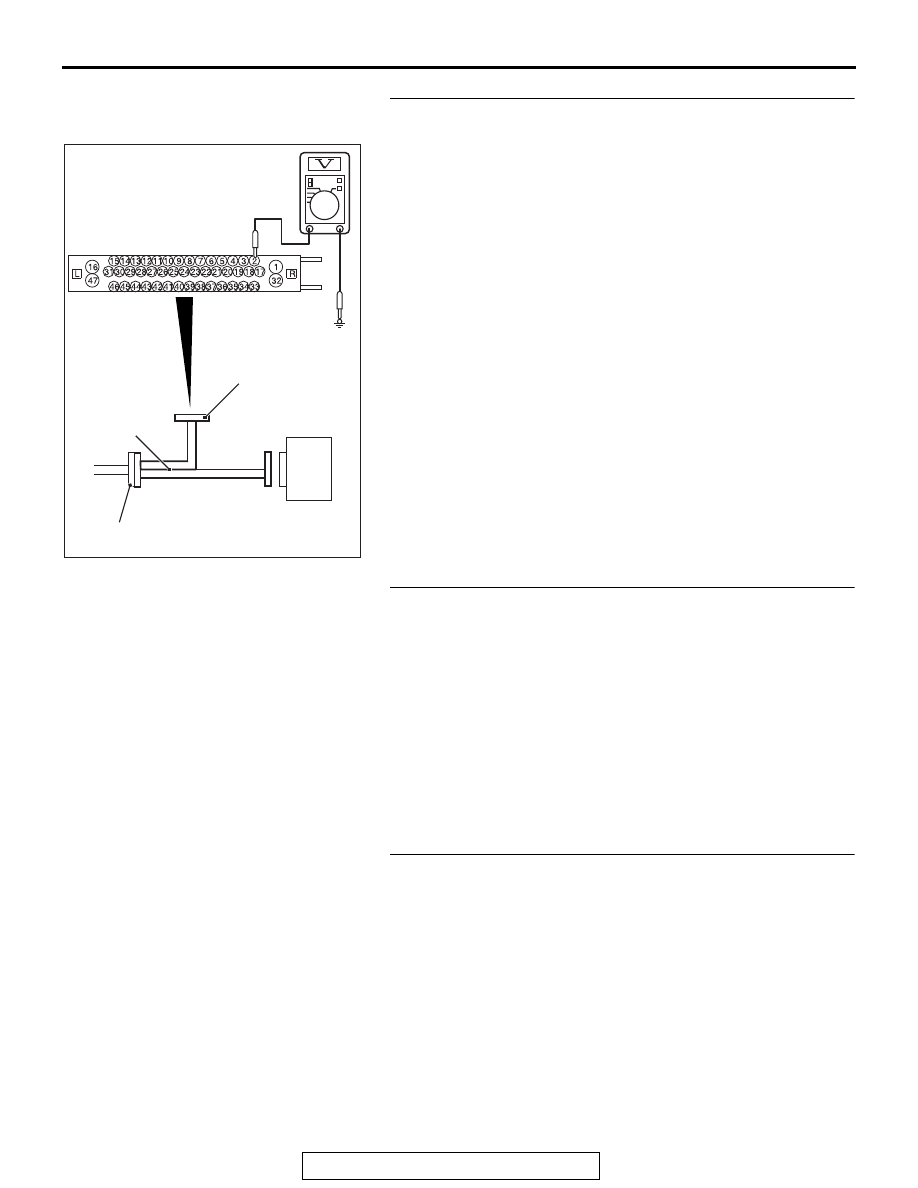

STEP 16. Voltage measurement at A-05 ASC-ECU

connector

(1) Disconnect the connector, connect the ASC check harness

(Special tool: MB991997) to the wiring harness-side

connector, and measure the voltage at the special tool

connector side.

NOTE: Do not connect the special tool to ASC-ECU.

(2) Measure the voltage between the terminal No. 2 and the

body ground.

OK: Battery positive voltage

Q: Is the check result normal?

YES : Go to Step 20.

NO : Go to Step 17.

STEP 17. Measure the voltage at the C-309 ETACS-ECU

connector.

(1) Disconnect the connector, and measure at the wiring

harness-side connector.

(2) Measure the voltage between the terminal No. 1 and the

body ground.

OK: Battery positive voltage

Q: Is the check result normal?

YES : Go to Step 18.

NO : Repair the wiring harness between C-309

ETACS-ECU connector terminal No. 1 and the fusible

link No. 34.

STEP 18. Measure the voltage at the C-315 ETACS-ECU

connector.

(1) Without disconnecting the connector, measure by

backprobing.

(2) Measure the voltage between the terminal No. 4 and the

body ground.

OK: Battery positive voltage

Q: Is the check result normal?

YES : Go to Step 20.

NO : Go to Step 19.

AC400817CN

ASC-ECU

MB991997

A-05 ASC-ECU

harness connector

Check harness