Mitsubishi Lancer Evolution X. Manual - part 126

BASIC BRAKE SYSTEM DIAGNOSIS

TSB Revision

BASIC BRAKE SYSTEM

35A-9

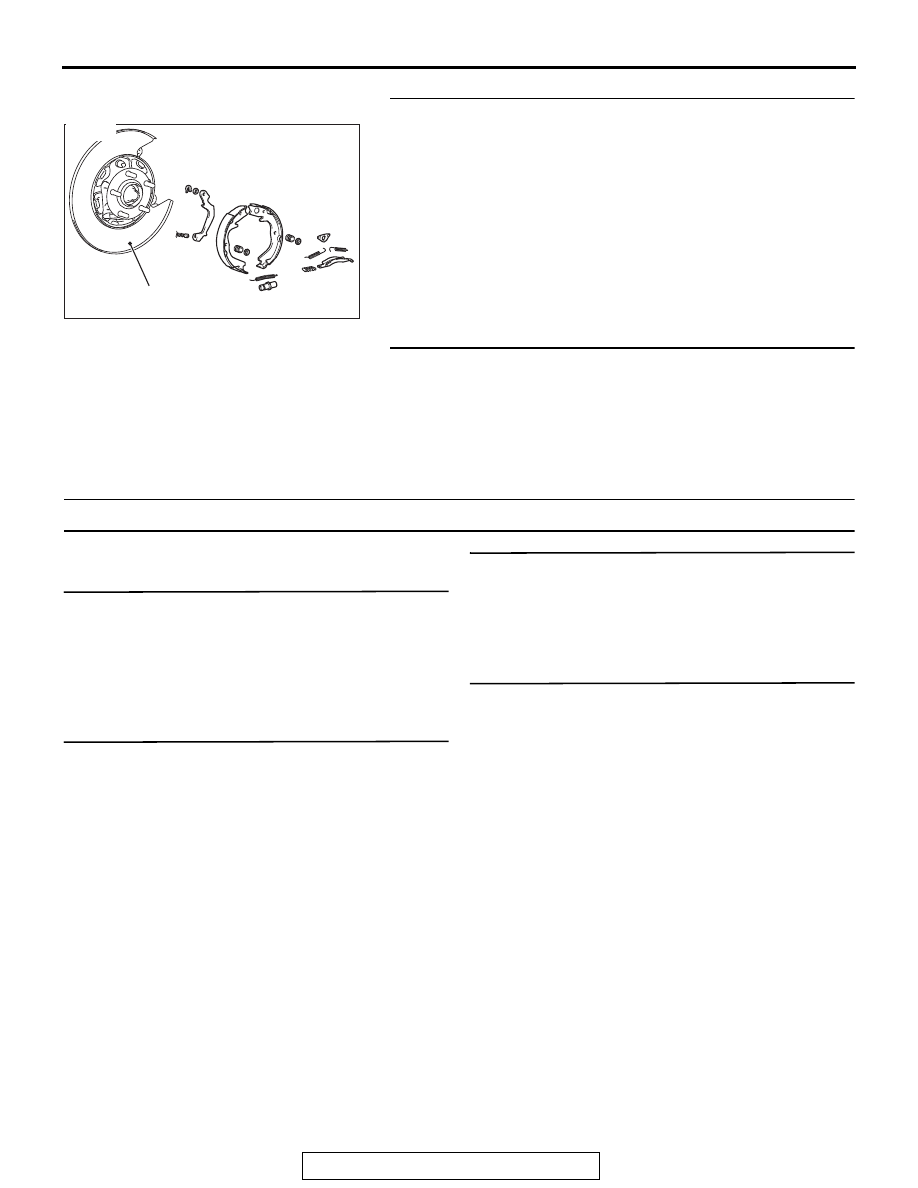

STEP 5. Check for bent backing plate(s).

Q: Is (Are) the backing plate(s) bent?

YES : Repair or replace the part. Then go to Step 6.

NO : Go to Step 6.

STEP 6. Recheck symptom.

Q: Is the symptom eliminated?

YES : The procedure is complete.

NO : Start over at step 1. If a new symptom surfaces, refer

to the symptom chart.

INSPECTION PROCEDURE 6: Squealing, Groaning or Chattering Noise when Brakes are Applied

DIAGNOSIS

STEP 1. Check the brake disk and pads for wear

or cutting.

Q: Is there wear or cutting?

YES :

Repair or replace the part. Then go to Step

4.

NO :

Go to Step 2.

STEP 2. Check the calipers for rust.

Q: Is there any rust?

YES :

Remove the rust. Then go to Step 4.

NO :

Go to Step 3.

STEP 3. Adjust the brake pedal.

Refer to

Q: Is the brake pedal adjusted correctly?

YES :

Go to Step 4.

NO :

Adjust the brake pedal. Then go to Step 4.

STEP 4. Recheck symptom.

Q: Is the symptom eliminated?

YES :

The procedure is complete.

NO :

Start over at step 1. If a new symptom

surfaces, refer to the symptom chart.

AC709382AD

Backing plate

<Rear>