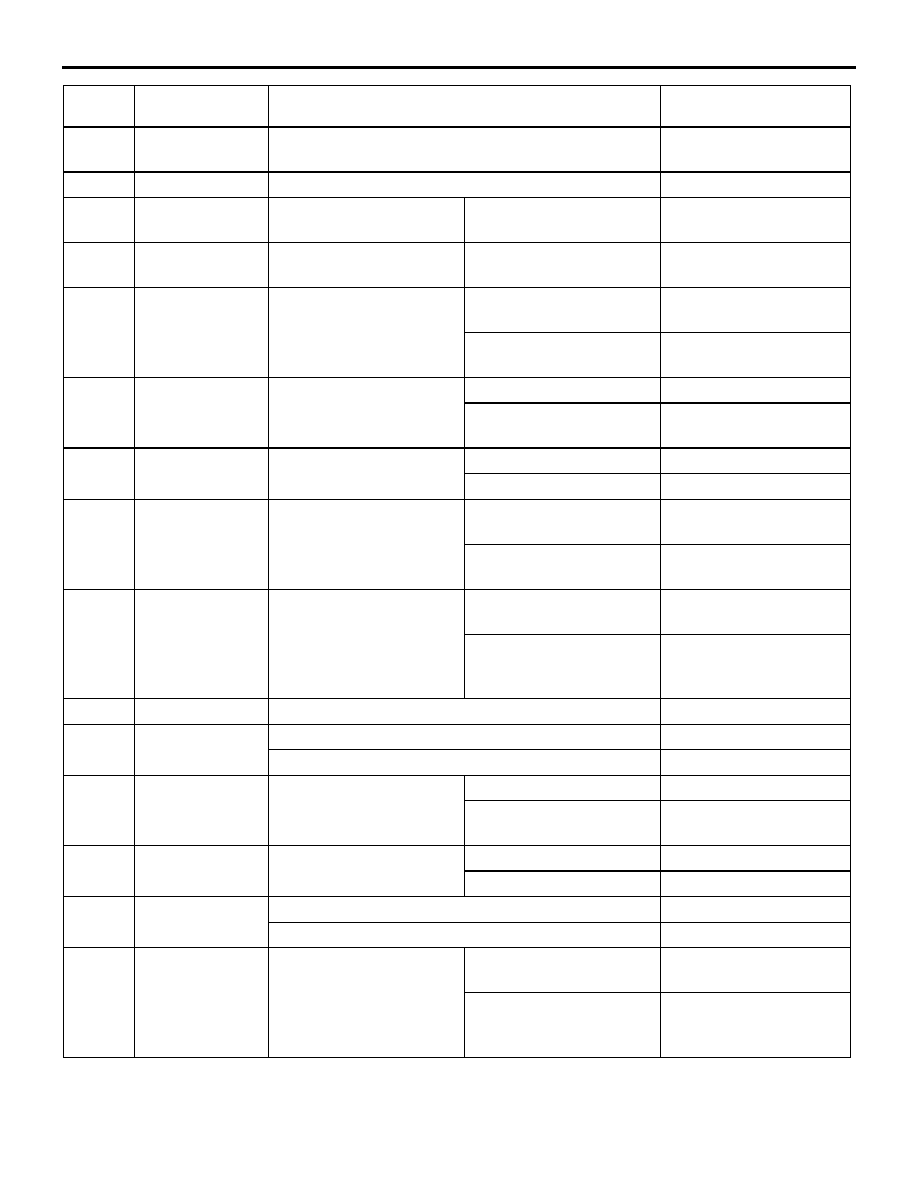

Mitsubishi Lancer Evolution IX. Manual - part 616

TROUBLESHOOTING <ACD>

MANUAL TRANSMISSION (FF)

22A-147

31

ECU backup

power supply

Any time

System voltage

32

Pressure sensor Ignition switch: ON

0.5

− 1.5 V

33

Steering wheel

sensor <ST-1>

Ignition switch: ON

Steering wheel: Turn

slowly

1

− 2 V ⇔ 2.5 − 4.5 V

flushing

34

Steering wheel

sensor <ST-2>

Ignition switch: ON

Steering wheel: Turn

slowly

1

− 2 V ⇔ 2.5 − 4.5 V

flushing

36

Idle switch

Ignition switch: ON

Accelerator pedal: Full

closed

1 V or less

Accelerator pedal:

Depress

4.5

− 5.0 V

37

Parking brake

switch

Ignition switch: ON

Parking brake lever: Pull 1 V or less

Parking brake lever:

Release

System voltage

38

Stop lamp switch Ignition switch: ON

Brake pedal: Depress

System voltage

Brake pedal: Release

1 V or less

39

TPS

Ignition switch: ON

Accelerator pedal: Full

closed

0.5

− 0.7 V

Accelerator pedal: Full

throttle

4.5

− 5.5 V

40

ACD mode

indicator lamp

<TARMAC>

Ignition switch: ON

ACD mode indicator lamp

position: TARMAC

0 V

ACD mode indicator lamp

position: Except for

above

Approx.10.5 V

42

ECU earth

Any time

1 V or less

43

Pressure sensor

power supply

Ignition switch: OFF

1 V or less

Ignition switch: ON

Approx.5.0 V

44

Steering wheel

sensor <ST-N>

Ignition switch: ON

Steering wheel: Neutral

1

− 2 V

Steering wheel: Turn from

the neutral position

2.5

− 4.5 V

47

ACD mode

switch

Ignition switch: ON

Switch: Press

System voltage

Switch: Release

0 V

48

ABS monitor

With ABS not active

System voltage

With ABS active

1.5 V or less

51

ACD mode

indicator lamp

<SNOW>

Ignition switch: ON

ACD mode indicator lamp

position: SNOW

0 V

ACD mode indicator lamp

position: Except for

above

Approx.10.5 V

Terminal

No.

Check item

Check condition

Normal state