Mitsubishi Lancer Evolution IX. Manual - part 356

ENGINE CONTROL

ENGINE AND EMISSION CONTROL

17-3

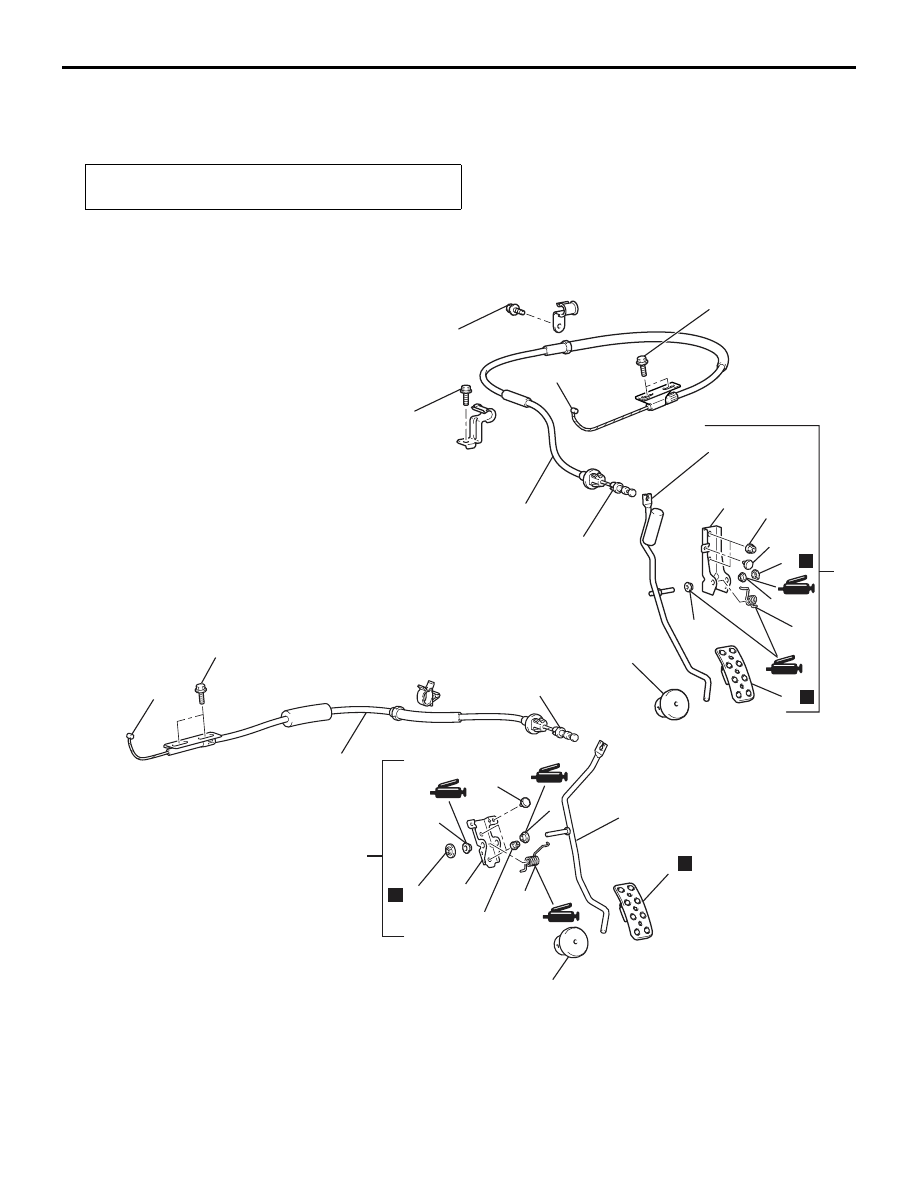

ACCELERATOR CABLE AND PEDAL

REMOVAL AND INSTALLATION

M1171001200608

Post-installation Operation

Adjusting the Accelerator Cable (Refer to

AC505002

1

10

4

6

7

8

6

2

11

5

9

12 ± 2 N·m

5.0 ± 1.0 N·m

11 ± 1 N·m

N

5.0 ± 1.0 N·m

AB

10

11

12

3

N

5

1

12

3

N

8

7

6

12 ± 2 N·m

9

4

N

6

5.0 ± 1.0 N·m

2

<R.H. drive vehicles>

<L.H. drive vehicles>

Accelerator pedal removal steps

>>

B

<< 1. Inner cable connection (Accelerator

pedal side)

2. Accelerator pedal assembly

>>

A

<< 3. Accelerator pedal pad

4. Push-on spring nut

5. Accelerator pedal arm assembly

6. Bushing

7. Spring

8. Stopper

9. Accelerator pedal bracket

Accelerator pedal removal steps