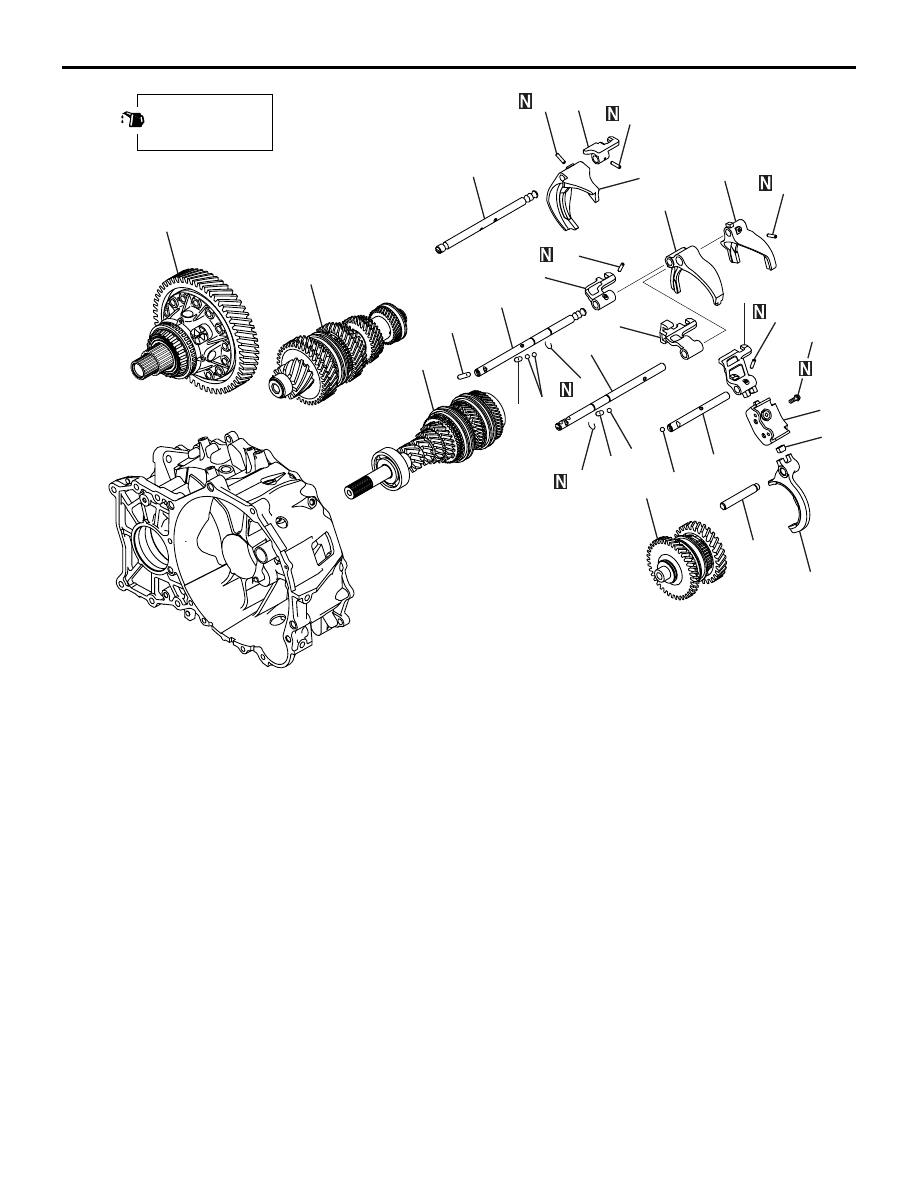

Mitsubishi Lancer Evolution IX. Manual - part 292

AK204166AF

28

29

30

31

32

33

34

35

35

48

36

36

37

38

39

40

41

42

43

44

51

45

46

47

49

50

52

53

54

55

56

57

14 ± 1 N·m

Apply gear oil to

all moving parts

before installation.

Disassembly steps

28. Reverse lever assembly

29. Shifter cap

30. Reverse fork rod

31. Reverse shift fork

32. Retaining pin

33. Reverse bracket

34. Reverse bracket fork rod

35. Interlock ball

36. Retaining pin

37. 1st-2nd bracket

38. 1st-2nd fork rod

39. 1st-2nd shift fork

40. Retaining pin

41. C-ring

42. 3rd-4th fork rod

43. Interlock pin

44. 3rd-4th bracket

45. Retaining pin

46. C-ring

47. 5th-6th fork rod

48. Interlock pin

49. 5th-6th shift fork

50. 3rd-4th shift fork

51. 5th-6th bracket

52. Interlock ball

53. Shift check sleeve

54. Main shaft assembly

55. Input shaft assembly

56. Reverse idler gear assembly

57. Center differential

TRANSMISSION

MANUAL TRANSMISSION OVERHAUL

22B-13

Reassembly steps

57. Center differential

>>A<<

56. Reverse idler gear assembly

>>A<<

55. Input shaft assembly

>>A<<

54. Main shaft assembly

38. 1st-2nd fork rod

37. 1st-2nd bracket

36. Retaining pin

>>B<<

39. 1st-2nd shift fork

>>C<<

53. Shift check sleeve

>>D<<

42. 3rd-4th fork rod

43. Interlock pin

>>D<<

44. 3rd-4th bracket

>>D<<

50. 3rd-4th shift fork

Disassembly steps (Continued)