Mitsubishi Lancer Evolution IX. Manual - part 106

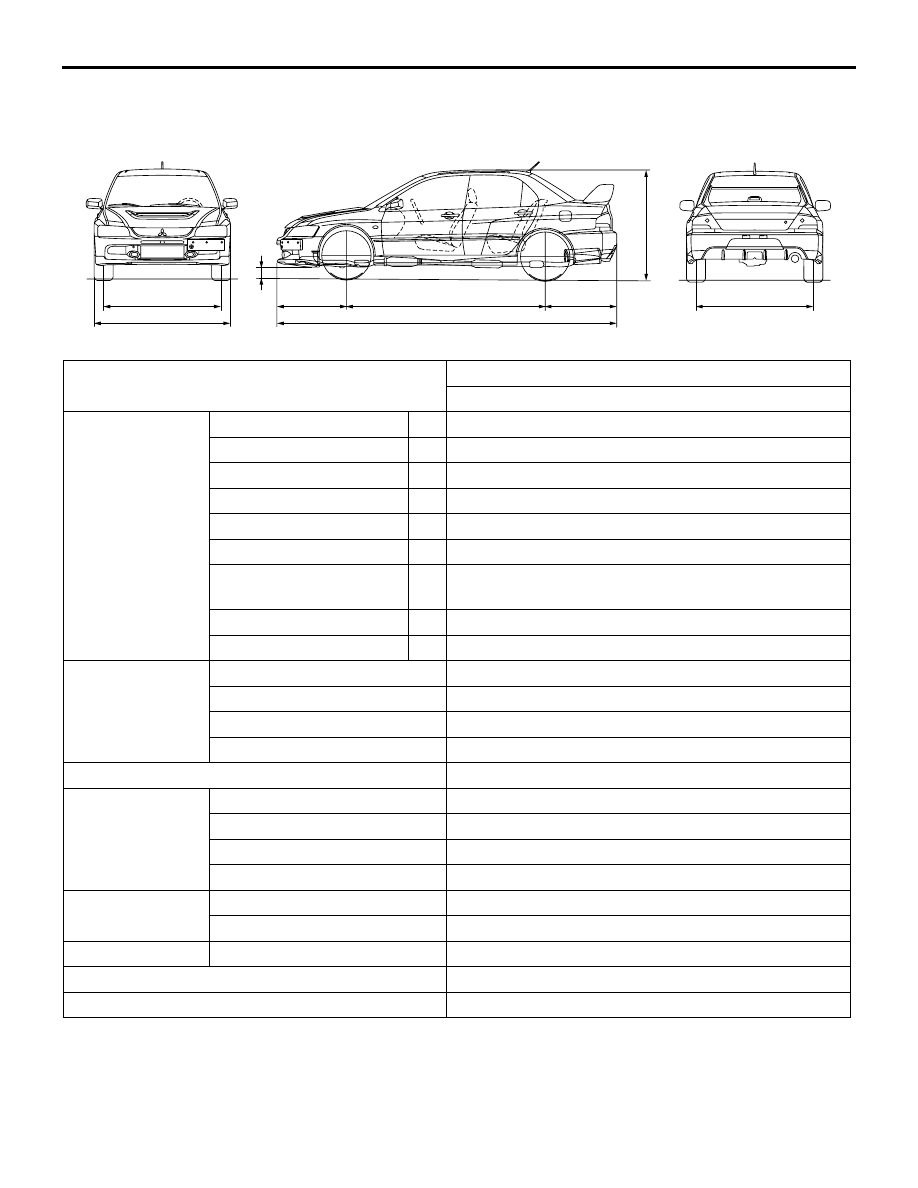

GENERAL DATA AND SPECIFICATIONS

GENERAL

00-17

GENERAL DATA AND SPECIFICATIONS

M1001000901045

AC505135

1

2

7

3

4

6

5

8

9

AB

Items

CT9A

SJGFZL6/R6

Vehicle

dimensions mm

Front track

1

1,515

Overall width

2

1,770

Front overhang

3

930

Wheel base

4

2,625

Rear overhang

5

935

Overall length

6

4,490

Ground clearance

(unladen)

7

140

Overall height (unladen)

8

1,450

Rear track

9

1,515

Vehicle weight kg Kerb weight

1,465

Max. gross vehicle weight

1,885

Max. axle weight rating-front

1,015

Max. axle weight rating-rear

900

Seating capacity

5

Engine

Model code

4G63 DOHC-MIVEC with intercooler turbocharger

Total displacement mL

1,997

Maximum output kW/r/min

206/6,500

Maximum torque N

⋅m/r/min

355/3,500

Transmission

Model code

W6MAA

Type

6-speed manual

Fuel system

Fuel supply system

MPI

Maximum speed km/h

250

Minimum turning radius m

5.9