Mitsubishi Lancer Evolution IX. Manual - part 86

WATER PUMP AND WATER HOSE

ENGINE OVERHAUL

11B-35

INSTALLATION SERVICE POINTS

>>A<< O-RING/WATER INLET PIPE

INSTALLATION

CAUTION

• Never allow any oil or grease to touch the

O-rings.

• Clamp the water inlet pipe only after installa-

tion of the thermostat case.

Replace the O-rings at both ends of the water inlet

pipe with new ones. Insert the O-rings into the water

pump and thermostat housing after wetting their

peripheries with water.

>>B<< ENGINE COOLANT

TEMPERATURE GAUGE UNIT

INSTALLATION

1. Remove all old sealant remaining on the threaded

hole in the engine coolant temperature gauge unit

and the thermostat housing.

NOTE: A new engine coolant temperature gauge

unit is coated with sealant. It does not require

coating with sealant before installation.

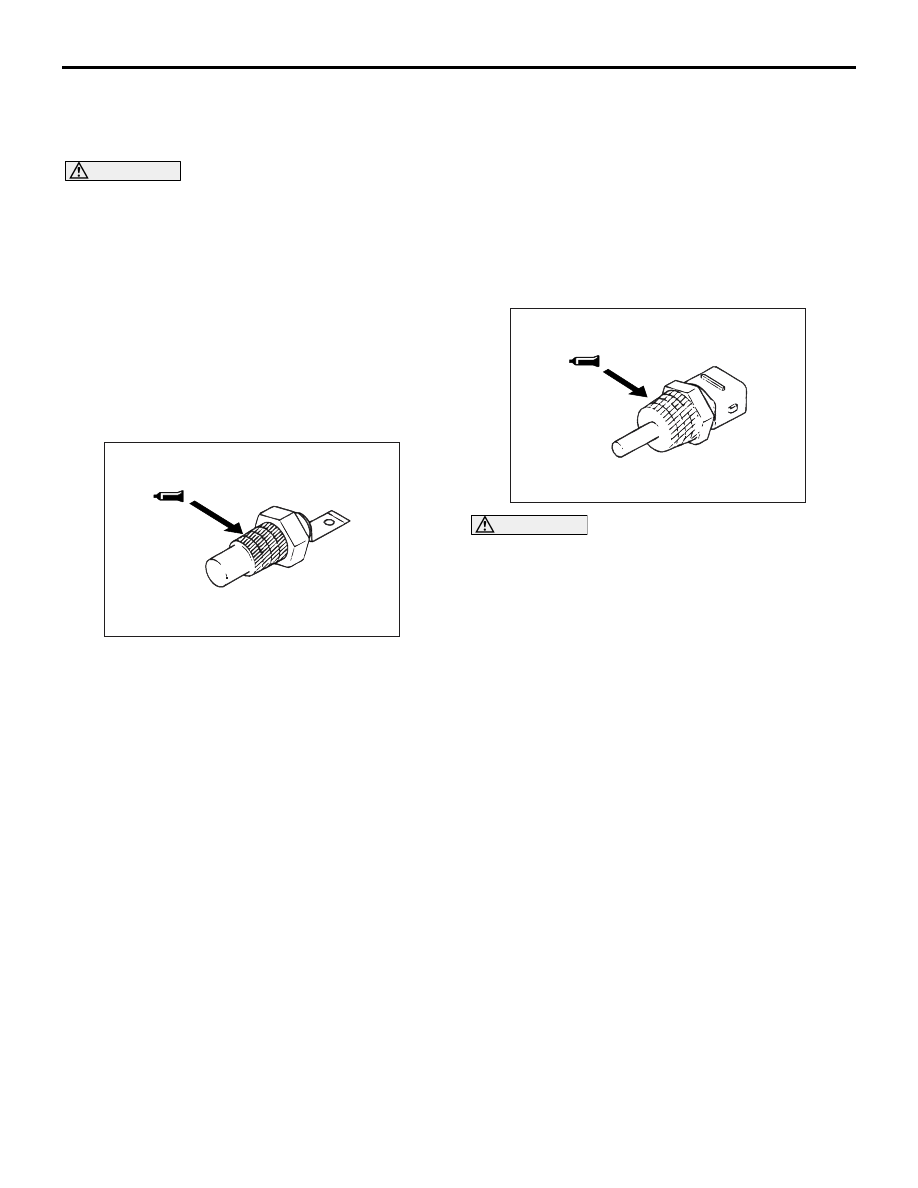

2. Apply sealant to the indicated threads of the

engine coolant temperature gauge unit.

Specified sealant:

3M Nut Locking Part No.4171 or equivalent

>>C<< ENGINE COOLANT

TEMPERATURE SENSOR INSTALLATION

CAUTION

When using a tool, avoid letting it touch the con-

nector portion which is made of plastic.

1. Remove all old sealant remaining on the threads

of the engine coolant temperature sensor and in

the threaded hole in the thermostat housing.

2. Apply sealant to the engine coolant temperature

sensor's threads indicated in the drawing.

Specified sealant:

3M ATD Part No.8660 or equivalent

AK202800AB

AK202799AB