Mitsubishi Lancer Evolution VI. Manual - part 104

CHASSIS ELECTRICAL –

Ignition Switch and Immobilizer System

54-20

REMOVAL SERVICE POINTS

A

A

"

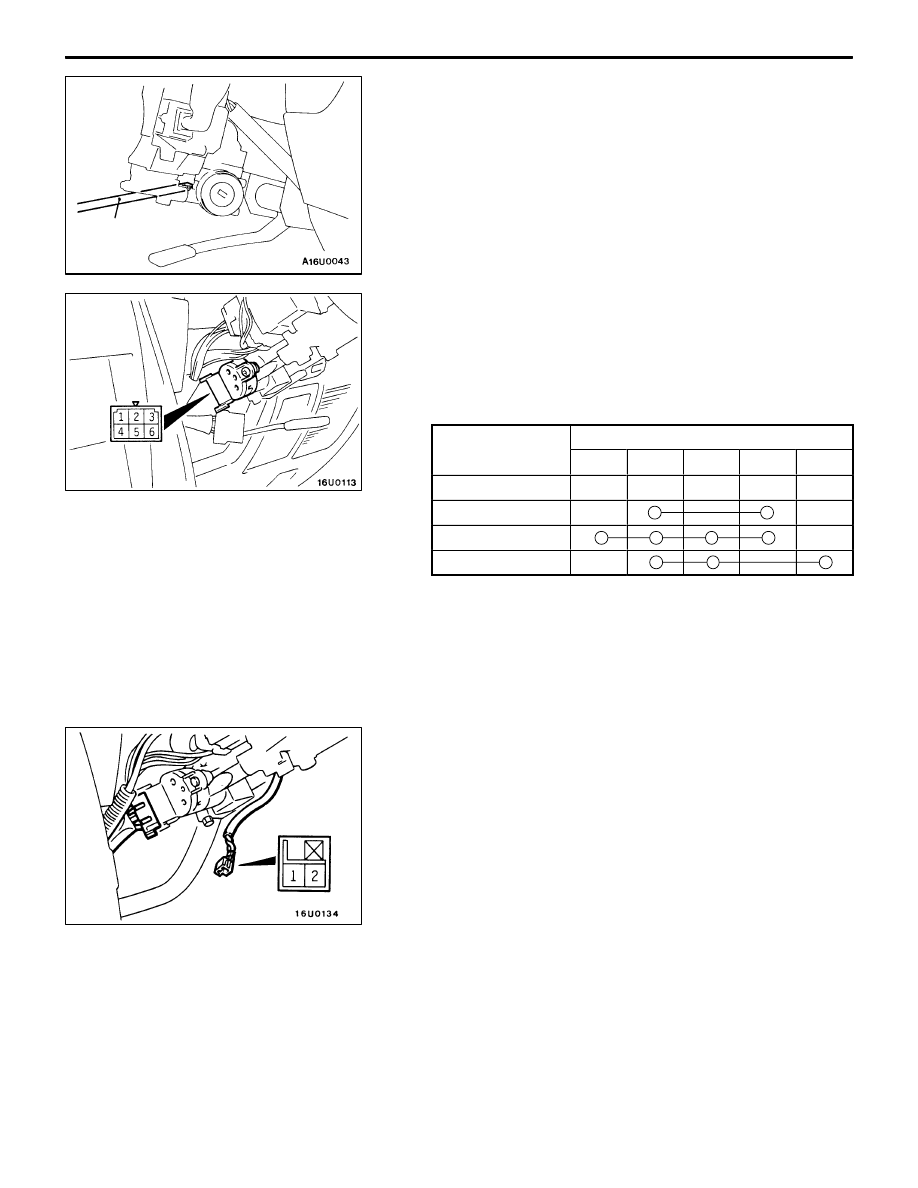

STEERING LOCK CYLINDER REMOVAL

1.

Insert the key in the steering lock cylinder and turn it

to the “ACC” position.

2.

Using a cross-tip (+) screwdriver (small) or a similar tool,

push the lock pin of the steering lock cylinder inward

and then pull the steering lock cylinder toward you.

INSPECTION

IGNITION SWITCH CONTINUITY CHECK

1.

Remove the column cover lower and upper.

2.

Disconnect the wiring connector from the ignition switch.

3.

Operate the switch, and check the continuity between

the terminals.

Ignition key

Terminal No.

Ignition key

position

1

2

3

5

6

LOCK

ACC

ON

START

IGNITION KEY RING ANTENNA CONTINUITY CHECK

Use a circuit tester to check the continuity between the

terminals.

Cross-tip (+)

screwdriver