Mitsubishi Lancer Evolution VI. Manual - part 39

MPI –

Troubleshooting

13-44

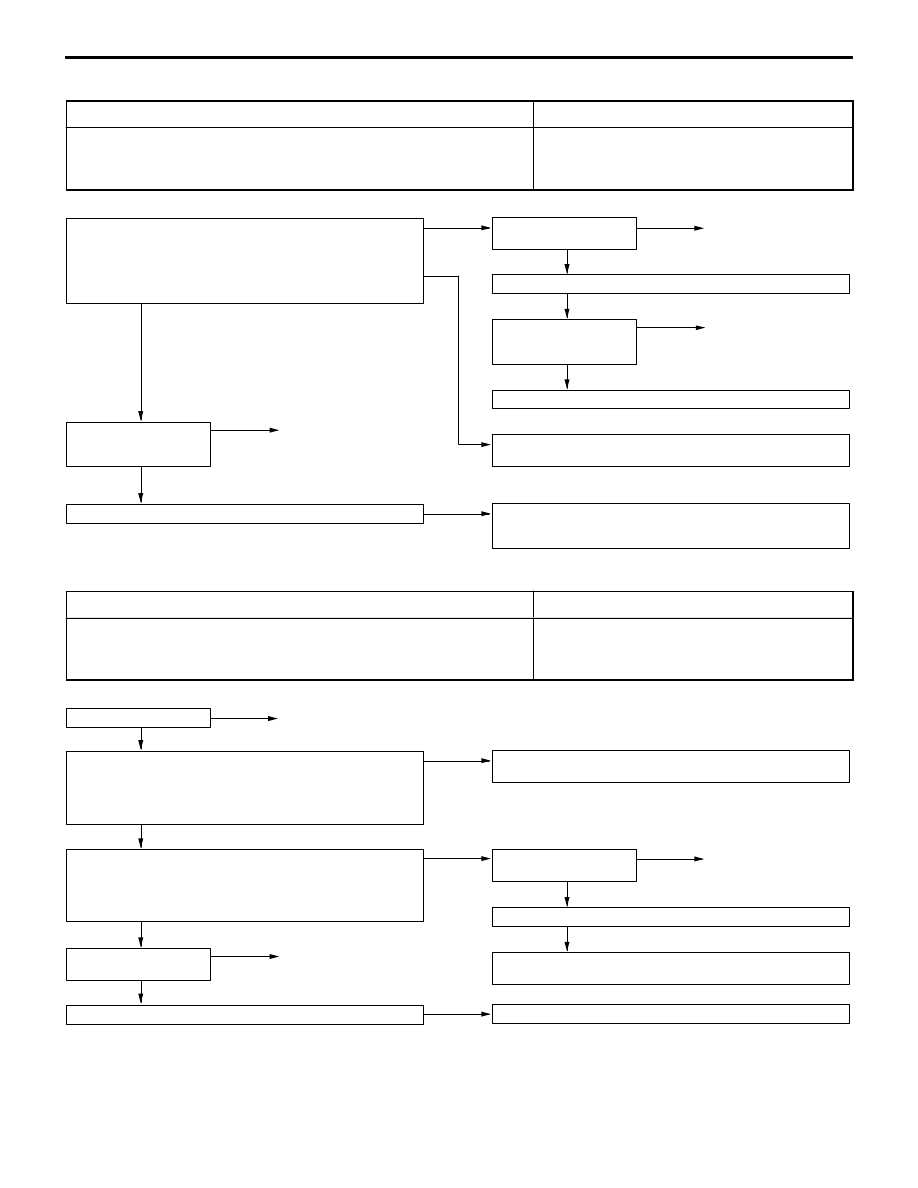

INSPECTION PROCEDURE 32

Ignition circuit system

Probable cause

The engine-ECU interrupts the ignition coil primary current by turning the power transistor

inside the engine-ECU ON and OFF.

D

Malfunction of ignition switch.

D

Improper connector contact, open or short-circuited

harness wire

D

Malfunction of the engine-ECU

Measure at the ignition coil connectors A-110, A-111.

D

Disconnect the connector and measure at the harness side.

1. Voltage between 1 and earth (Ignition switch: ON)

OK: System voltage

2. Continuity between 2 and earth

OK: Continuity

1. NG

Check the following

connectors: B-65, B-76

NG

Repair

OK

Check trouble symptom.

NG

Check the harness wire

between ignition coil and

ignition switch connector.

NG

Repair

OK

Check the ignition switch.

2. NG

Check the harness wire between ignition coil connector and earth,

and repair if necessary.

OK

Check the following

connectors:

A-110, A-111

NG

Repair

OK

Check trouble symptom.

NG

Check ignition coil and power transistor unit system. (Refer to

P.13-16, INSPECTION PROCEDURE FOR DIAGNOSIS CODE

44.)

INSPECTION PROCEDURE 33

Idle speed control (ISC) servo (Stepper motor) system

Probable cause

The engine-ECU controls the intake air volume during idling by opening and closing

the servo valve located in the bypass air passage.

D

Malfunction of ISC servo

D

Improper connector contact, open or short-circuited

harness wire

D

Malfunction of the engine-ECU

Check the ISC servo.

NG

Replace

OK

Measure at the ISC servo connector A-18.

D

Disconnect the connector and measure at the harness side.

D

Voltage between 2 and earth, and 5 and earth (Ignition switch:

ON)

OK: System voltage

NG

Check the harness wire between control relay and ISC servo con-

nector, and repair if necessary.

OK

Measure at the engine-ECU connector B-59.

D

Disconnect the connector, measure at the harness side.

D

Voltage between each of 4, 5, 17, 18 and earth (Ignition switch:

ON)

OK: System voltage

NG

Check the following

connector: A-18

NG

Repair

OK

Check trouble symptom.

NG

Check harness wire between engine-ECU and ISC servo connector,

and repair if necessary.

OK

Check the following

connector: B-59

NG

Repair

OK

Check trouble symptom.

NG

Replace the engine-ECU.