Mitsubishi Lancer Evolution VI. Manual - part 29

MPI –

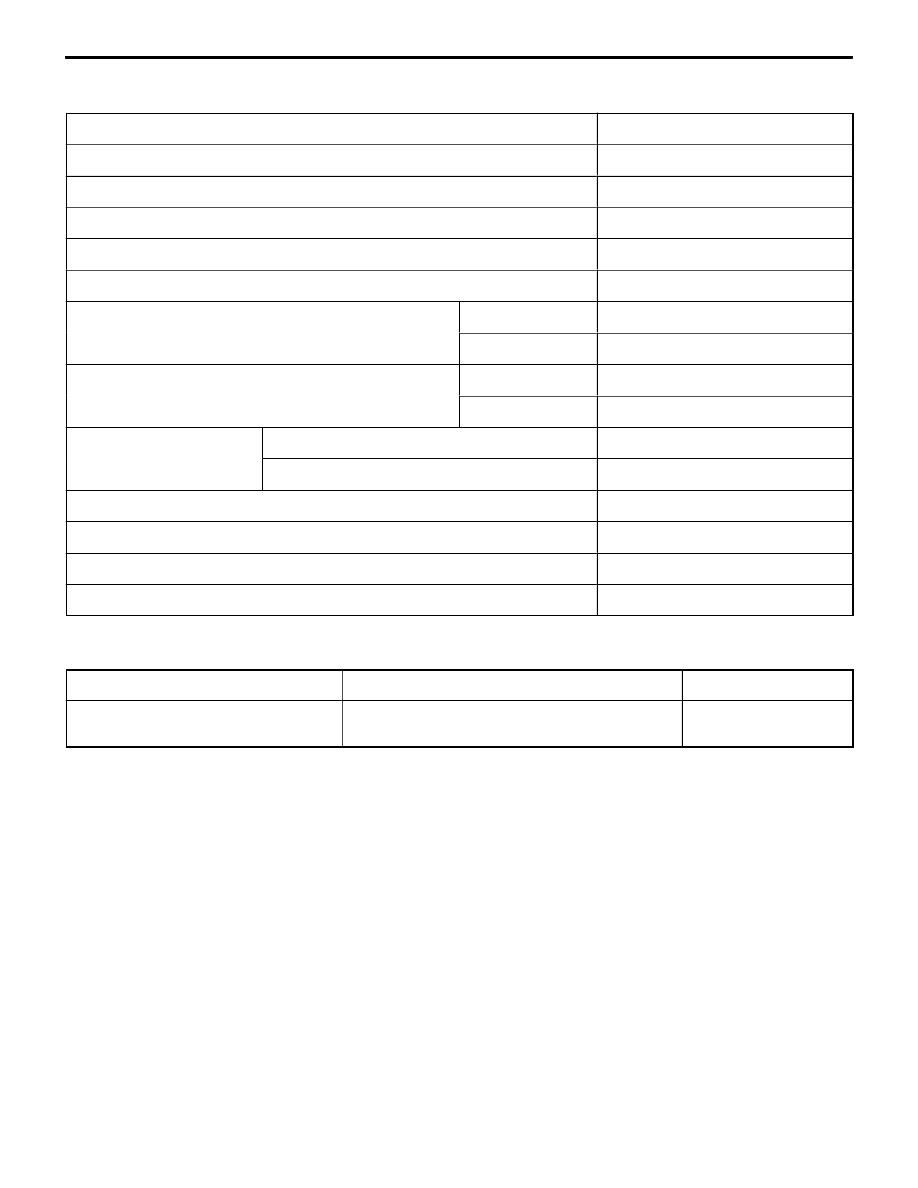

Service Specifications / Sealant

13-4

SERVICE SPECIFICATIONS

Items

Specifications

Basic ignition timing

_

BTDC

5

±

3

Basic idle speed rpm

850

±

50

Throttle position sensor adjusting voltage mV

400 – 1,000

Throttle position sensor resistance k

Ω

3.5 – 6.5

ISC servo coil resistance (at 20

_

C)

Ω

28 – 33

Intake air temperature sensor resistance k

Ω

At 20

_

C

2.3 – 3.0

At 80

_

C

0.30 – 0.42

Coolant temperature sensor resistance k

Ω

At 20

_

C

2.1 – 2.7

At 80

_

C

0.26 – 0.36

Fuel pressure kPa

When vacuum hose is connected

230

When vacuum hose is disconnected

289 – 309

Injector coil resistance

Ω

2 – 3

Amount of injector fuel leak drop/min

1 or less

Oxygen sensor output voltage V

0.6 – 1.0

Fuel pressure control valve coil resistance (at 20

_

C)

Ω

28 – 36

SEALANT

Item

Specified sealant

Remark

Engine coolant temperature sensor

threaded portion

3M Nut Locking Part No.4171 or equivalent

Drying sealant