Mitsubishi Lancer Evolution VI. Manual - part 26

ENGINE –

Alternator

11-79

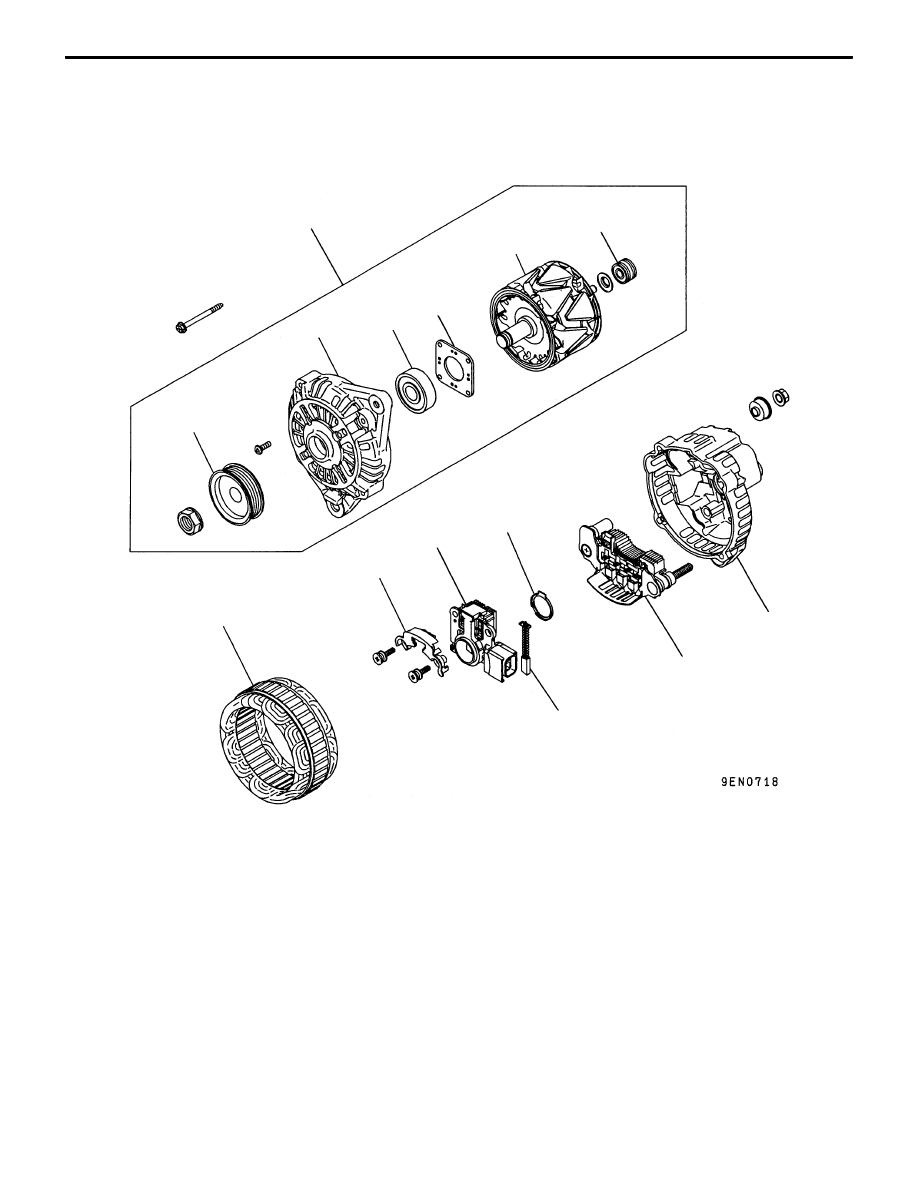

ALTERNATOR

DISASSEMBLY AND REASSEMBLY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Disassembly steps

A

A

"

1. Front bracket assembly

A

B

"

2. Alternator pulley

"

B

A

3. Rotor

4. Rear bearing

5. Bearing retainer

6. Front bearing

7. Front bracket

A

C

"

8. Stator

9. Plate

A

C

" "

A

A

10. Regulator assembly

11. Brush

12. Slinger

13. Rectifier

14. Rear bracket