Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual - part 68

OIL PAN AND OIL PUMP

TSB Revision

ENGINE OVERHAUL <3.0L ENGINE>

11D-43

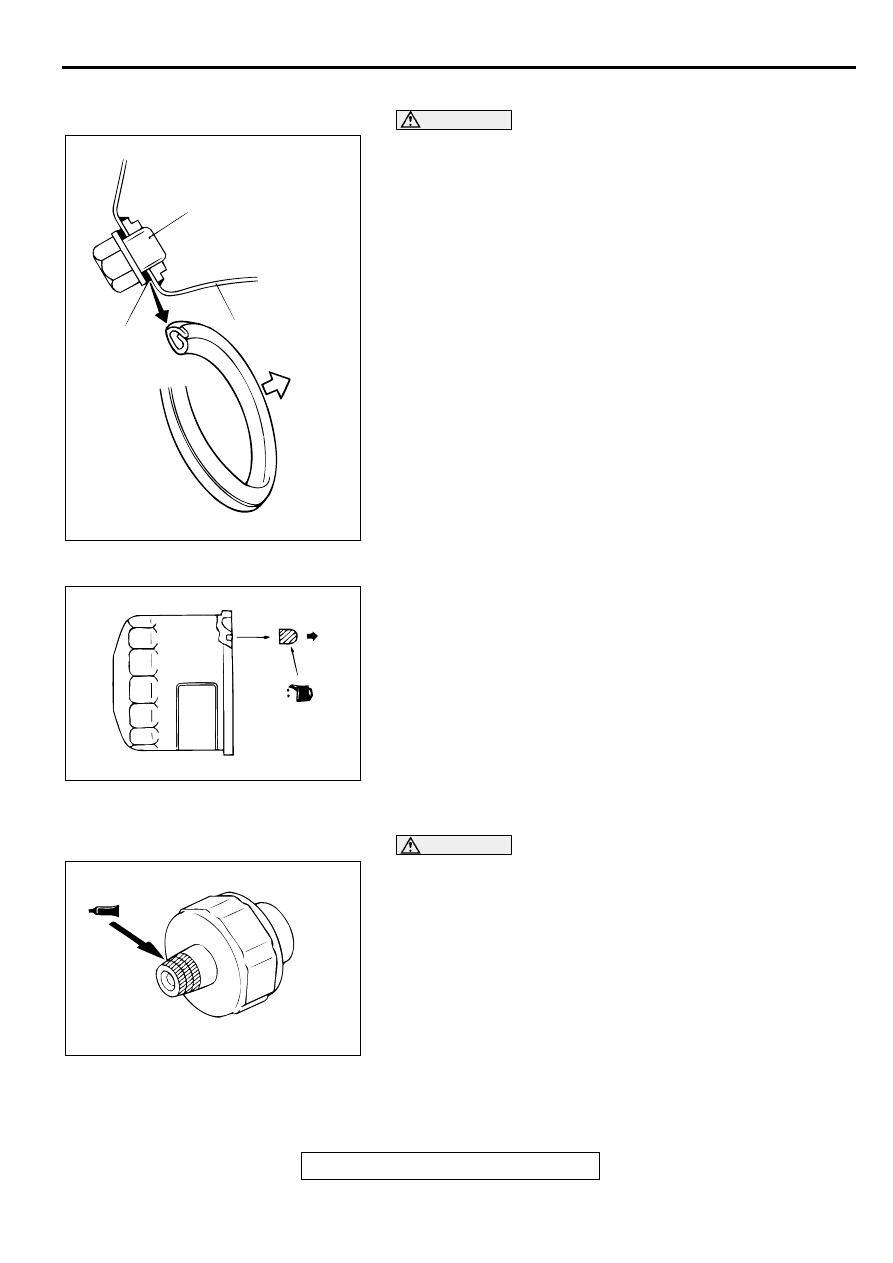

>>F<< DRAIN PLUG GASKET INSTALLATION

CAUTION

If the gasket is installed in the wrong direction, oil leaks

will be occurred.

Install the drain plug gasket in the direction shown.

>>G<< OIL FILTER INSTALLATION

1. Clean the installation surface of the filter bracket.

2. Apply engine oil to the O-ring of the oil filter.

3. Install the oil filter to the bracket and tighten it to the

specified torque.

Tightening torque: 14

±

2 N

⋅

m (122

±

17 in-lb)

4. If no torque wrench can be used for tightening, follow the

following procedure.

(1) Screw in the oil filter until its O-ring contacts the oil filter

bracket.

(2) Tighten the oil filter 3/4 turn.

>>H<< OIL PRESSURE SWITCH INSTALLATION

CAUTION

Be careful not to block the oil passage with sealant.

1. Apply 3M

AAD Part number 8672 or equivalent to the

thread of oil pressure switch.

2. Tighten the switch to the specified torque.

Tightening torque: 10

±

2 N

⋅

m (87

±

17 in-lb)

AKX00726

DRAIN PLUG

OIL

PAN

SIDE

GASKET

OIL PAN

AB

AKX00692

BRACKET

SIDE

AB

AKX00688