Mitsubishi Eclipse. Technical Information Manual (1994) - part 12

1-26

ENGINE <NON-TURBO> Control System

ACTUATORS AND CONTROL

FUEL INJECTORS

The

engine uses electrically operated top feed

fuel injectors. The MFI relay (automatic shut down

relay) supplies battery voltage to the fuel injectors.

The PCM controls the ground path for each injector

in sequence. By switching the ground paths on and

off, the PCM fine-tunes injector pulse width. Injector

pulse width refers to the amount of time an injector

operates.

The PCM determines injector synchronization from

the camshaft position sensor and crankshaft position

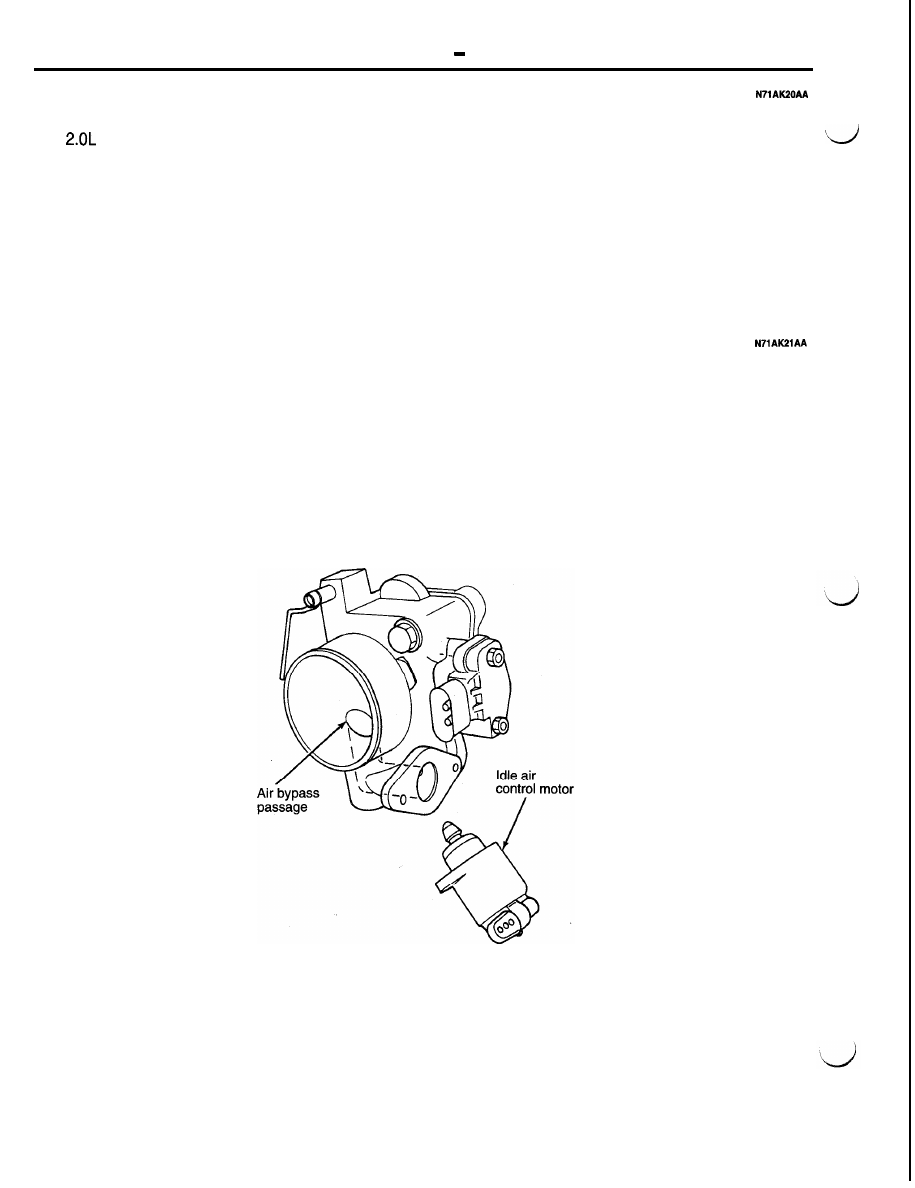

IDLE AIR CONTROL MOTOR

The idle air control (IAC) motor is mounted on the

throttle body. The PCM operates the idle air control

motor. The PCM adjusts engine idle speed through

the idle air control motor to compensate for engine

load or ambient conditions.

The throttle body has an air bypass passage that

provides air for the engine during closed throttle

idle. The idle air control motor pintle protrudes into

the air bypass passage and regulates air flow

through it.

sensor inputs. The PCM grounds the MFI and fuel

pump relays after receiving the camshaft position

sensor and crankshaft position sensor inputs.

The PCM energizes the injectors in a sequential

order during all engine operating conditions except

start-up. For the first injector pulse width during

start-up, all injectors are energized at the same

time. Once the PCM determines crankshaft position,

it beings energizing the injectors in sequence.

The PCM adjusts engine idle speed by moving the

IAC motor pintle in and out of the bypass passage.

The adjustments are based on inputs the PCM re-

ceives. The inputs include the throttle position sen-

sor, crankshaft position sensor, coolant temperature

sensor, vehicle speed sensor and various switch

operations (brake, park/neutral, air conditioning,

power steering).

AFU0079