Mitsubishi Eclipse. Manual - part 886

CRANKSHAFT AND CYLINDER BLOCK

TSB Revision

ENGINE OVERHAUL <3.0L>

11D-53

3. For example, if the crankshaft journal outside diameter

identification color is "Yellow " and the cylinder block bearing

bore identification mark is "III," select a bearing whose

identification color is "Green".

If there is no identification color paint on the crankshaft,

measure the journal outside diameter and select a bearing

appropriate for the measured value.

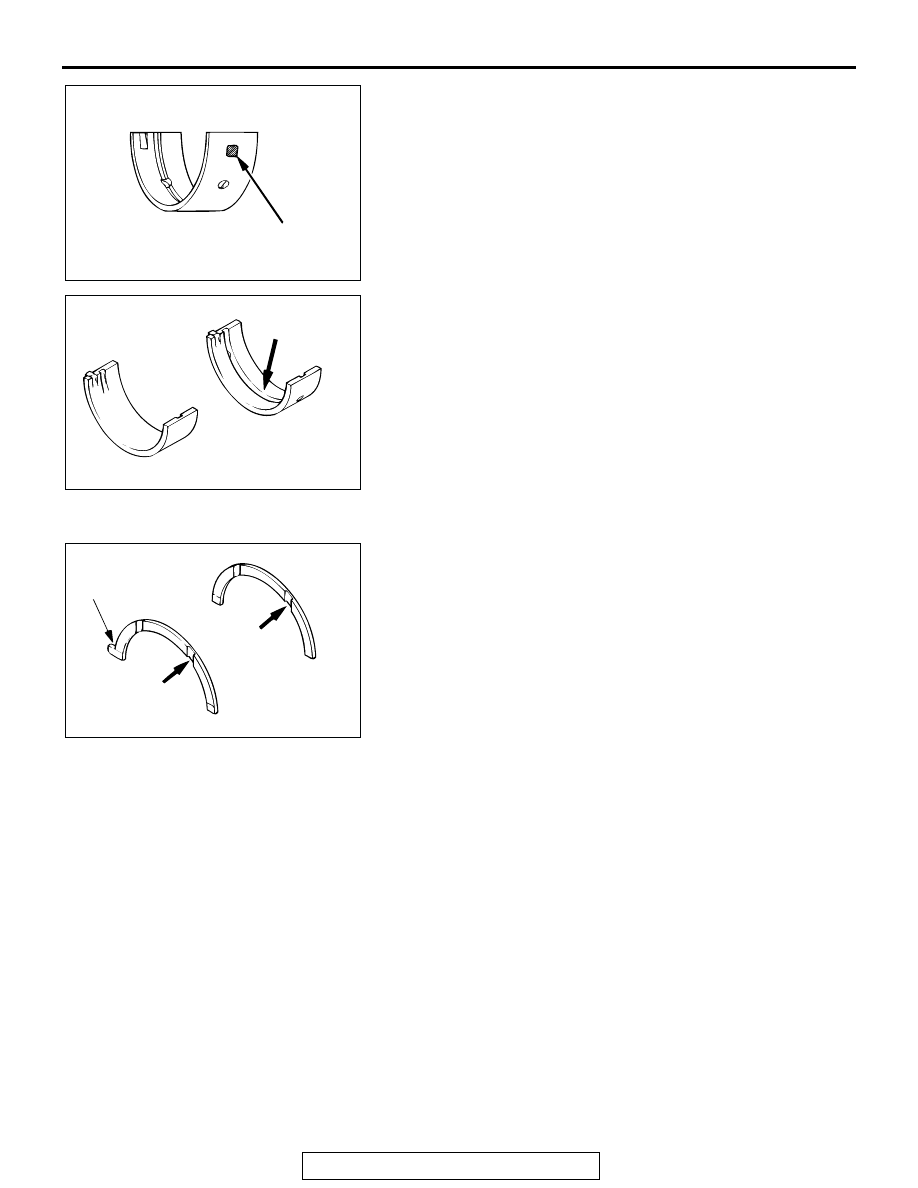

4. Install the bearings having a groove to the cylinder block.

5. Install the bearings having no groove to the bearing cap.

.

>>C<< CRANKSHAFT THRUST BEARING INSTALLATION

1. Install the thrust bearings in the number 3 bearing bore in

the cylinder block and in the bearing cap. For easier

installation, apply engine oil to the bearings; this will help

hold them in position.

2. The thrust bearings must be installed with their groove

toward the crankshaft web. The two thrust bearings are

different from each other. One has a tab while the other has

no tab. Be careful not to confuse them.

.

AKX00621

IDENTIFICATION COLOR

AB

AKX00623

GROOVE

FOR UPPER

FOR LOWER

AB

AKX00679

TAB

GROOVE

THRUST BEARING

"B"

GROOVE

THRUST BEARING "A"

AB