Mitsubishi Eclipse. Manual - part 783

AUTOMATIC TRANSAXLE DIAGNOSIS

TSB Revision

AUTOMATIC TRANSAXLE

23A-141

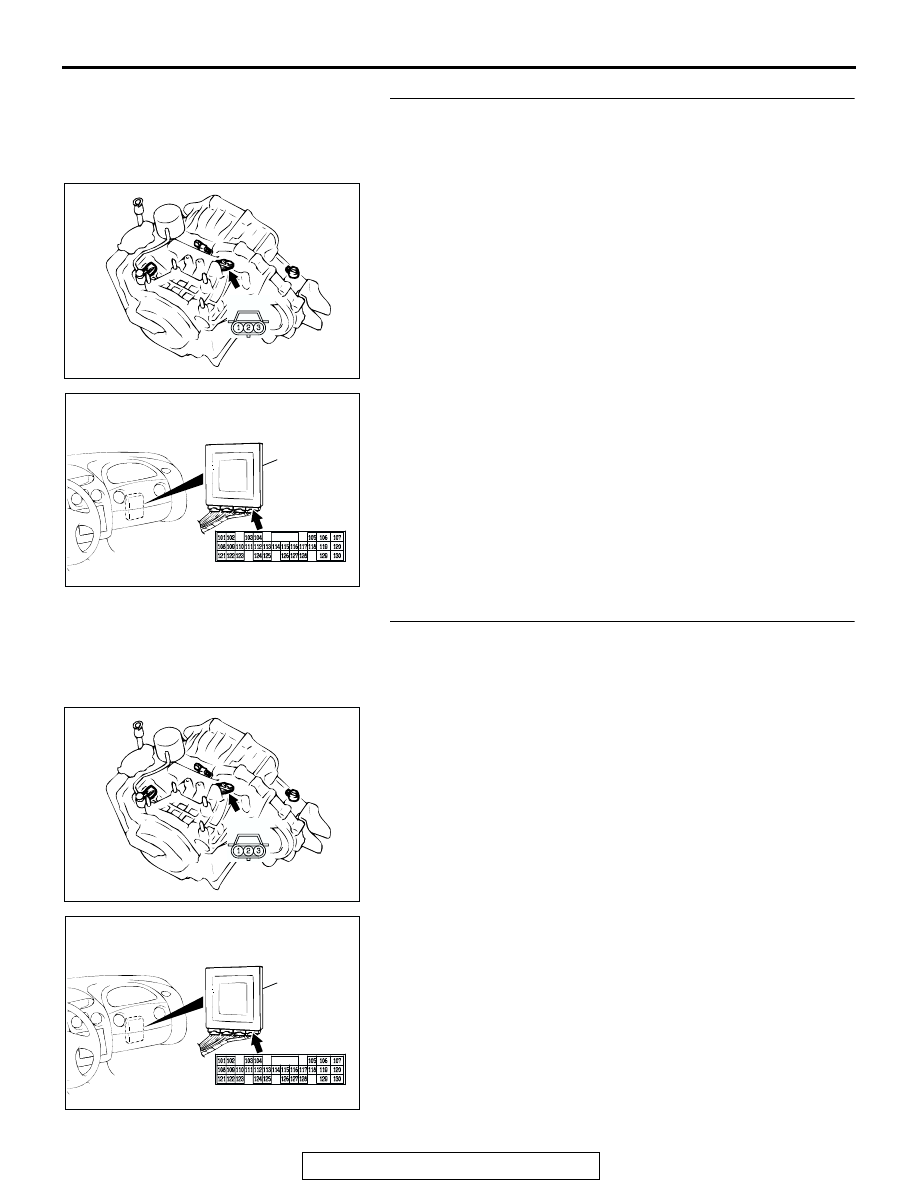

STEP 9. Check output shaft speed sensor connector B-38

and PCM connector C-61 <2.4L Engine> or C-63 <3.0L

Engine> for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Are the connectors and terminals in good condition?

YES : Go to Step 10.

NO : Repair or replace the damages components. Refer to

GROUP 00E, Harness Connector Inspection

STEP 10. Check the harness for short circuit to ground

between output shaft speed sensor connector B-38

terminal 2 and PCM connector C-61 <2.4L Engine> or C-63

<3.0L Engine> terminal 104.

Q: Is the harness wire in good condition?

YES : Go to Step 11.

NO : Repair or replace the harness wire.

AC001837AI

CONNECTOR: B-38

B-38

AC001657

CONNECTOR: C-61 <2.4L ENGINE> OR

C-63 <3.0L ENGINE>

PCM

BC

C-61 <2.4L ENGINE> OR C-63 <3.0L ENGINE>

AC001837AI

CONNECTOR: B-38

B-38

AC001657

CONNECTOR: C-61 <2.4L ENGINE> OR

C-63 <3.0L ENGINE>

PCM

BC

C-61 <2.4L ENGINE> OR C-63 <3.0L ENGINE>