Mitsubishi Eclipse. Manual - part 706

EMISSION CONTROL

TSB Revision

ENGINE AND EMISSION CONTROL

17-105

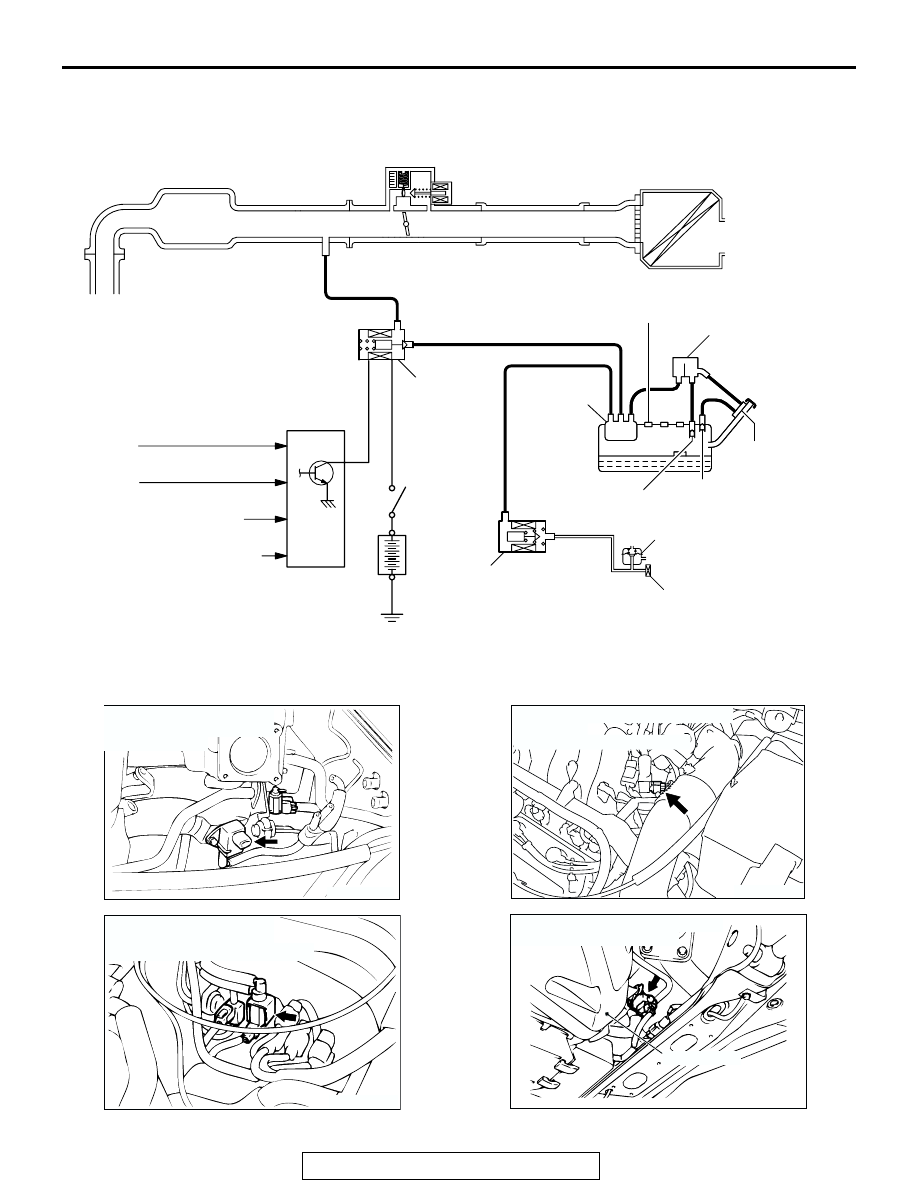

<3.0L ENGINE>

COMPONENT LOCATION

M1173007500186

AK300573

FUEL TANK DIFFERENTIAL

PRESSURE SENSOR

LIQUID SEPARATOR

EVAPORATIVE

EMISSION

CANISTER

EVAPORATIVE

EMISSION

PURGE

SOLENOID

ON: OPEN

ECM <M/T>

PCM <A/T>

INTAKE AIR TEMPERATURE

SENSOR

ENGINE COOLANT

TEMPERATURE SENSOR

VOLUME AIRFLOW SENSOR

FUEL

TANK

MFI RELAY

FUEL OVERFLOW

LIMITER VALVE

FUEL CUT

OFF VALVE

LEVELING VALVE

EVAPORATIVE EMISSION

VENTILATION VALVE

AIR FILTER

EVAPORATIVE EMISSION

VENTILATION SOLENOID

ON: CLOSED

AB

BAROMETRIC PRESSURE

SENSOR

AK103688

EVAPORATIVE EMISSION

PURGE SOLENOID VALVE

<2.4L ENGINE>

AD

AK103743AF

EVAPORATIVE EMISSION

PURGE SOLENOID VALVE

<3.0L ENGINE – WITHOUT IMT>

AK102961

AC

EVAPORATIVE EMISSION PURGE

SOLENOID

<3.0L ENGINE – WITH IMT>

AKX01305

EVAPORATIVE EMISSION

VENTILATION SOLENOID

FUEL TANK

AC