Mitsubishi Eclipse. Manual - part 702

AUTO-CRUISE CONTROL

TSB Revision

ENGINE AND EMISSION CONTROL

17-89

AUTO-CRUISE CONTROL SYSTEM COMPONENT

CHECK

M1172001700286

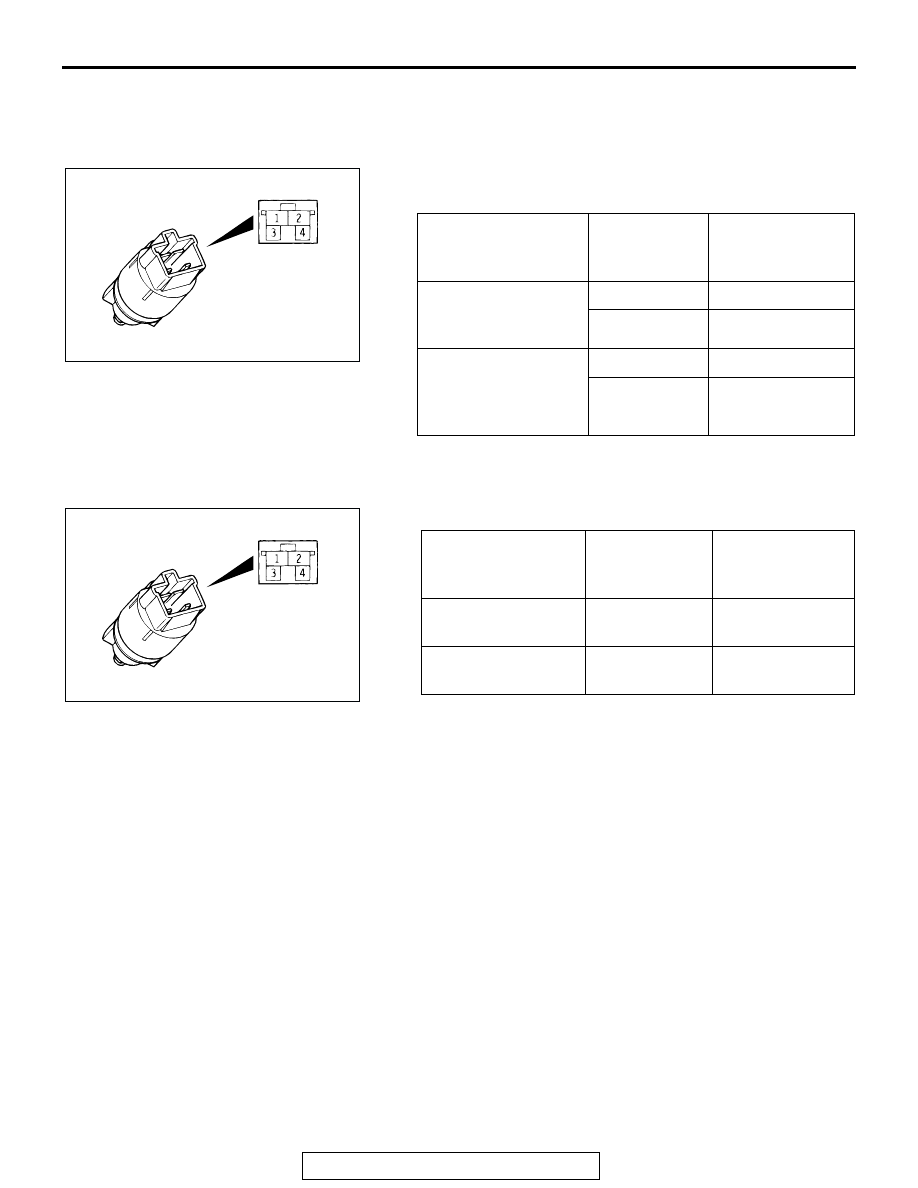

Stoplight Switch

1. Disconnect the connector.

2. Check for continuity between the terminals of the switch.

Clutch Pedal Position Switch

1. Disconnect the connector.

2. Check for continuity between the terminals of the switch.

Transmission Range Switch ("N" Position)

Refer to GROUP 23A, On-vehicle Service

− Essential Service

.

Throttle Position Sensor

For 2.4L engine, refer to GROUP 13A, On-vehicle Service

−

Throttle Position Sensor Check

.

For 3.0L engine, refer to GROUP 13B, On-vehicle Service

−

Throttle Position Sensor Check

.

MEASUREMENT

CONDITION

TERMINAL

CONNECTOR

OF TESTER

SPECIFIED

CONDITION

When brake pedal is

depressed. (for

stoplight circuit)

1

− 2

Less than 2 ohms

3

− 4

Open circuit

When brake pedal is

not depressed. (for

auto-cruise control

circuit)

1

− 2

Open circuit

3

− 4

Less than 2 ohms

ACX01180 AB

MEASUREMENT

CONDITION

TERMINAL

CONNECTOR

OF TESTER

SPECIFIED

CONDITION

When clutch pedal is

depressed.

1

− 2

Less than 2 ohms

When clutch pedal is

not depressed.

1

− 2

Open circuit

ACX01180 AB