Mitsubishi Eclipse. Manual - part 603

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L>

13B-955

STEP 3. Using scan tool MB991958, check data list.

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

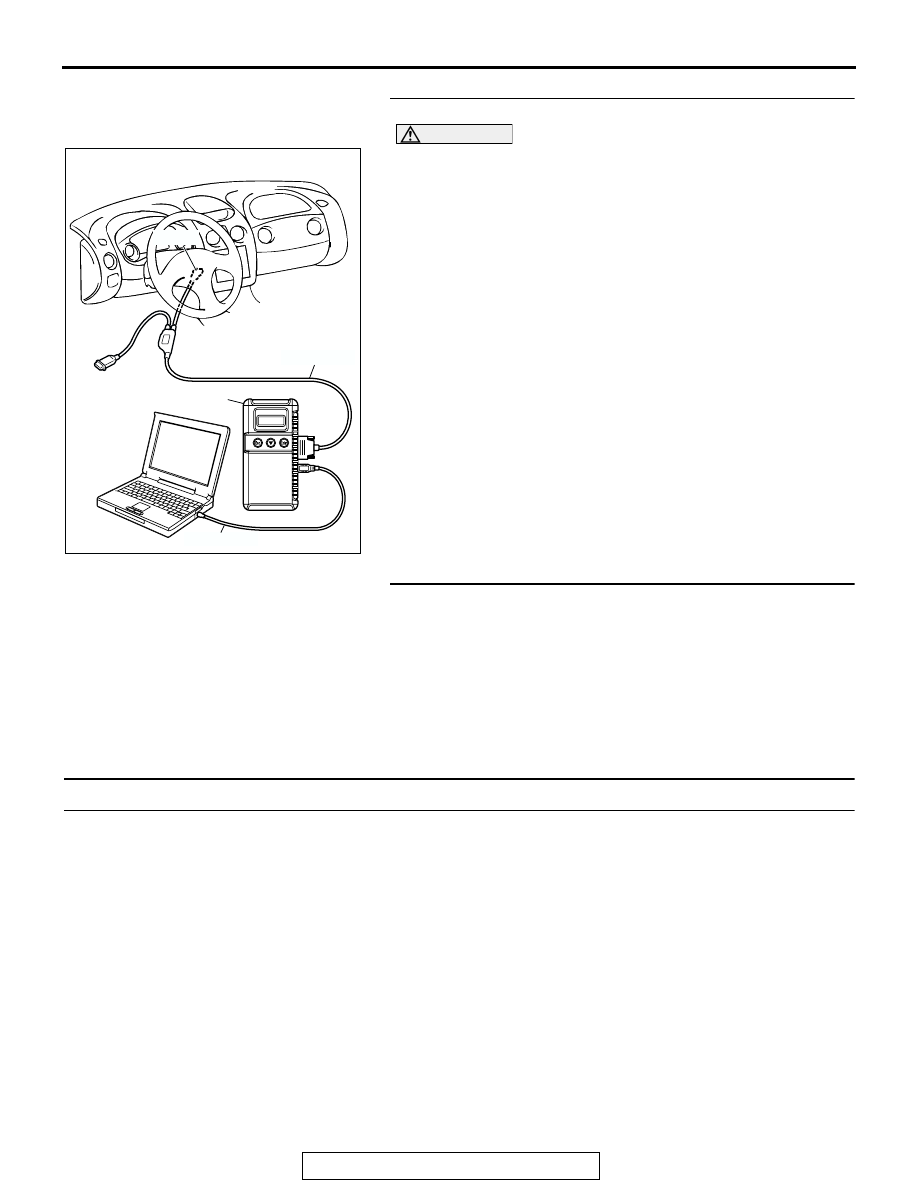

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Check the following items in the data list. Refer to, Data List

Reference Table

a. Item 21: Engine Coolant Temperature Sensor.

(4) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Are they operating properly?

YES : Go to Step 4.

NO : Repair or replace. Then confirm that the malfunction

symptom is eliminated.

STEP 4. Adjust the basic idle speed.

Refer to, Basic Idle Speed Adjustment for the adjustment pro-

cedure

.

Standard value: 700

± 50 r/min

Q: Is the idle speed normal?

YES : Refer to, Clean the throttle valve area

NO : The check is completed.

INSPECTION PROCEDURE 11: When the engine is cold, it stalls at idle (die out).

.

COMMENT

• In such cases as the above, the air/fuel mixture

may be inappropriate when the engine is cold.

.

TROUBLESHOOTING HINTS (The most likely

causes for this case: )

• Malfunction of the IAC system.

• Malfunction of the throttle body.

• Malfunction of the injector system.

• Malfunction of the ignition system.

DIAGNOSIS

Required Special Tools:

• MB991958: Scan Tool (MUT-III Sub Assembly)

• MB991824: V.C.I.

• MB991827: USB Cable

• MB991911: Main Harness B

AK300810

AB

MB991911

16-PIN

MB991827

MB991824