Mitsubishi Eclipse. Manual - part 551

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L>

13B-747

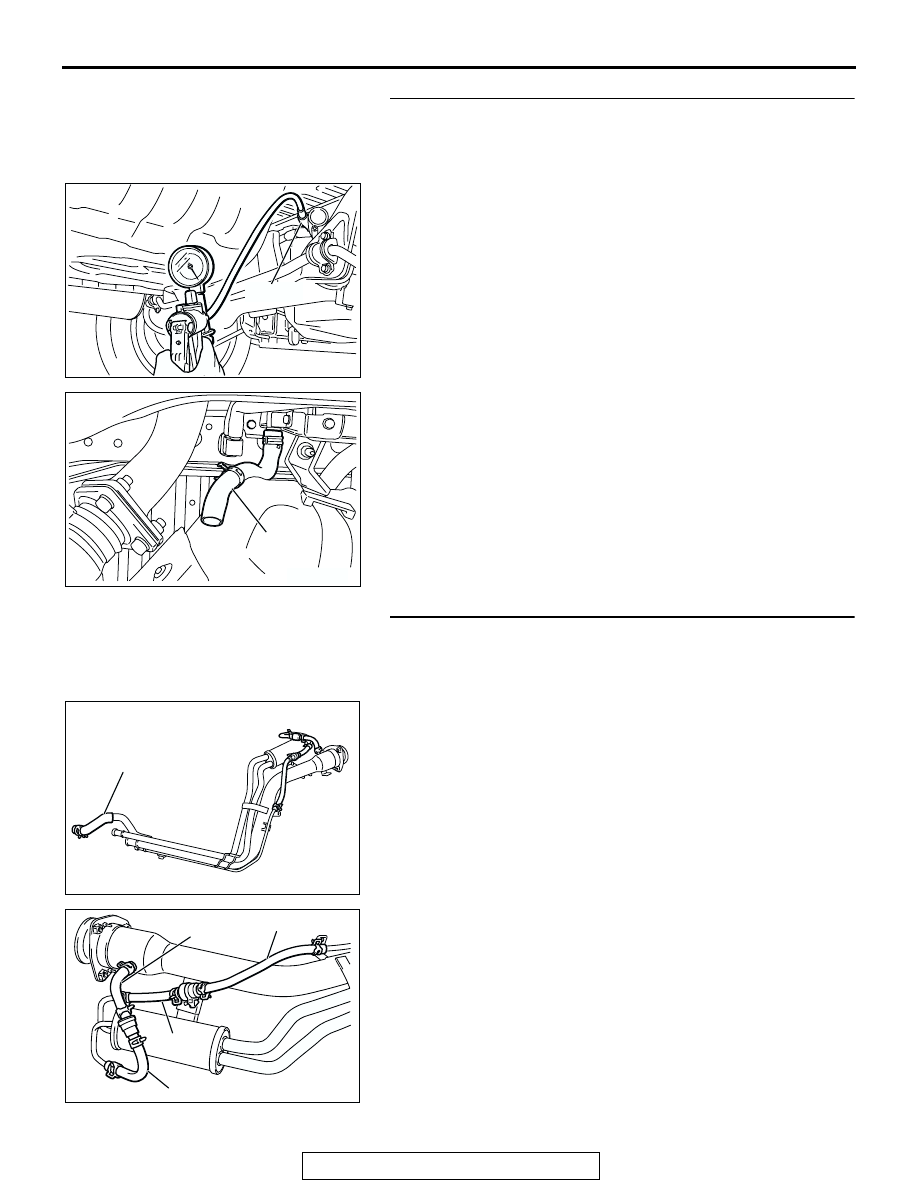

STEP 21. Check for clogging in the evaporator line from

hose J to hose K.

(1) Remove the fuel tank. (Refer to GROUP 13C, Fuel Tank

(2) Disconnect hose J at the liquid separator side, and then

connect a hand vacuum pump to the hose.

(3) Unplug the hose K at the fuel tank side.

(4) Apply a pressure on the vacuum pump, air should pass

through the hose K.

(5)

Q: Are the hoses good condition?

YES : Go to Step 22.

NO : Replace the inferior hose, and reinstall the fuel tank.

(Refer to GROUP 13C, Fuel Tank

.) Then go

to Step 26.

STEP 22. Check for lclogging in the evaporator line hose I,

L, M, N and hose O.

(1) Remove the filler neck assembly. (Refer to GROUP 13C,

Fuel Tank

(2) The clogging test with a hand vacuum pump on each hose

from hoses I, L, M, N and O.

Q: Are the hoses in good condition?

YES : Go to Step 23.

NO : Replace the inferior hose, and reinstall the filler neck

assembly. (Refer to GROUP 13C, Fuel Tank

.) Then go to Step 26.

AC02040 AB

HOSE J

AC002038 AB

HOSE K

AC002032

AB

HOSE I

AB

AC002039

AB

AB

HOSE O

HOSE L

HOSE N

HOSE M