Mitsubishi Eclipse. Manual - part 538

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <3.0L>

13B-695

Sensor (The sensors below are determined to be

normal)

• Volume airflow sensor

• Barometric pressure sensor

• Intake air temperature sensor

• Engine coolant temperature sensor

.

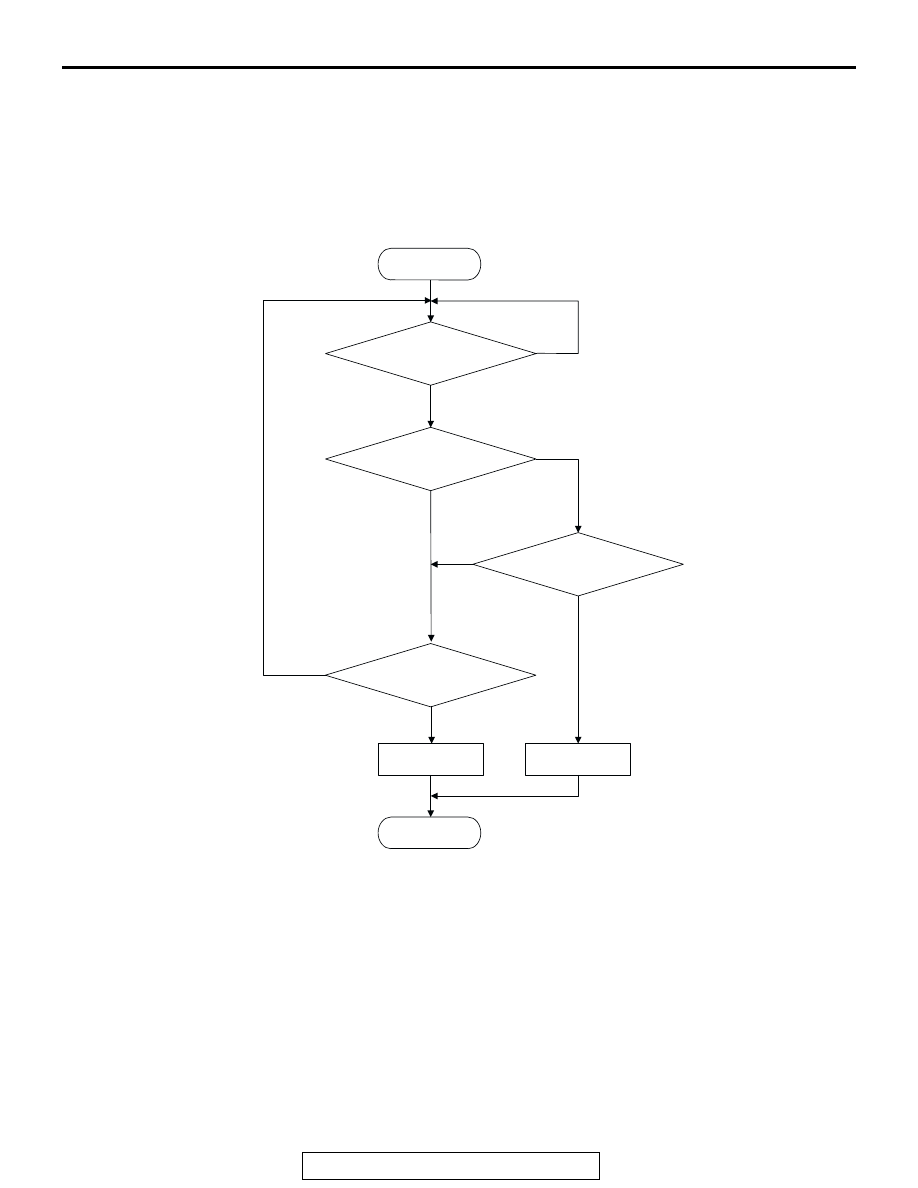

LOGIC FLOW CHARTS (Monitor Sequence)

.

DTC SET CONDITIONS

Test Conditions: For Test to Run

• Intake air temperature is higher than 5°C (41°C).

• Engine speed is 1,600 r/min or more.

• Volumetric efficiency is between 20 and 70 per-

cent.

Judgment Criteria

• When the evaporative emission purge solenoid is

off, the fuel differential pressure sensor output

voltage remains 1.0 volt or less for ten seconds.

.

OBD-ll DRIVE CYCLE PATTERN

Refer to Diagnostic Function

− OBD-ll Drive Cycle −

Procedure 1

− Evaporative Emission System Leak

Monitor

.

TROUBLESHOOTING HINTS

The most likely causes for this code to be set are:

• Fuel tank differential pressure sensor failed.

• Open fuel tank differential pressure sensor cir-

cuit, or loose connector.

• ECM <M/T> or PCM <A/T> failed.

.

NO

YES

CONTINUOUS

FAILURE FOR 10 SECS

START

END

NO

NO

NO

YES

YES

YES

MALFUNCTION

GOOD

MONITORING

CONDITIONS

OUTPUT VOLTAGE

< 1.0V

OUTPUT VOLTAGE

> 4.0V

AC210306

RANGE CHECK - MIN/MAX