Mitsubishi Eclipse. Manual - part 229

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L>

13A-409

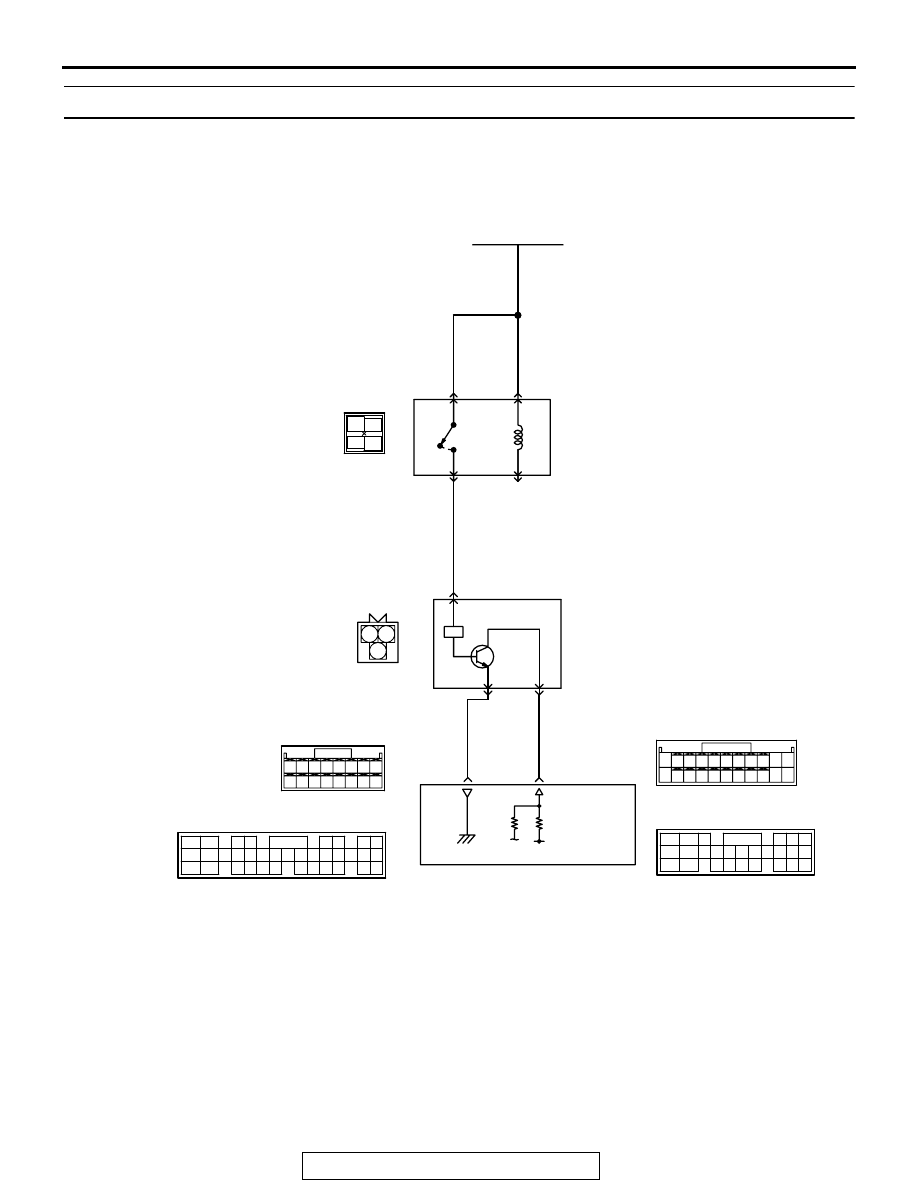

DTC P0335: Crankshaft Position Sensor Circuit

AK101516

1 2

3

RED

-

WHITE

RED

-

WHITE

RED

-

WHITE

RED

BROWN

GREEN-

RED

BATTERY

MFI

RELAY

CRANKSHAFT

POSITION

SENSOR

B-20

MU802603

C-54 <A/T>

(MU803781)

C-60 <M/T>

(MU803772)

89 <M/T>

*2

45 <A/T>

*4

40 <M/T>

*1

16 <A/T>

*3

4

1

2

3

3

1

2

5 V

ENGINE CONTROL

MODULE (ECM) <M/T>

OR

POWERTRAIN CONTROL

MODULE (PCM) <A/T>

42 43

48 49 50 51 52 53 54 55 56 57

46

45

44

58 59

60 61 62 63

64 65 66

47

41

82

78

81

80

89 90 91 92

79

87

71

74

73

72

76

75

77

85

88

83 84

86

Crankshaft Position Sensor Circuit

2

3 4

5 6

7 8

9

11 12 13 14 15 16 17 18 19 20

30

21 22 23

24 25

26 27 28 29

3132 33

34 35

1

10

C-50 <A/T>

(MU803784)

NOTE

*1: ECM connector C-53 <M/T>

*2: ECM connector C-60 <M/T>

*3: PCM connector C-50 <M/T>

*4: PCM connector C-54 <A/T>

C-53 <M/T>

(MU803771)

34

33

32

36

35

37

42

45

31

39

38

46

40 41

43 44

3 4

1 2

A-18X