Mitsubishi Colt Ralliart. Manual - part 290

FORWARD CLUTCH

CONTINUOUSLY VARIABLE TRANSMISSION OVERHAUL

23B-33

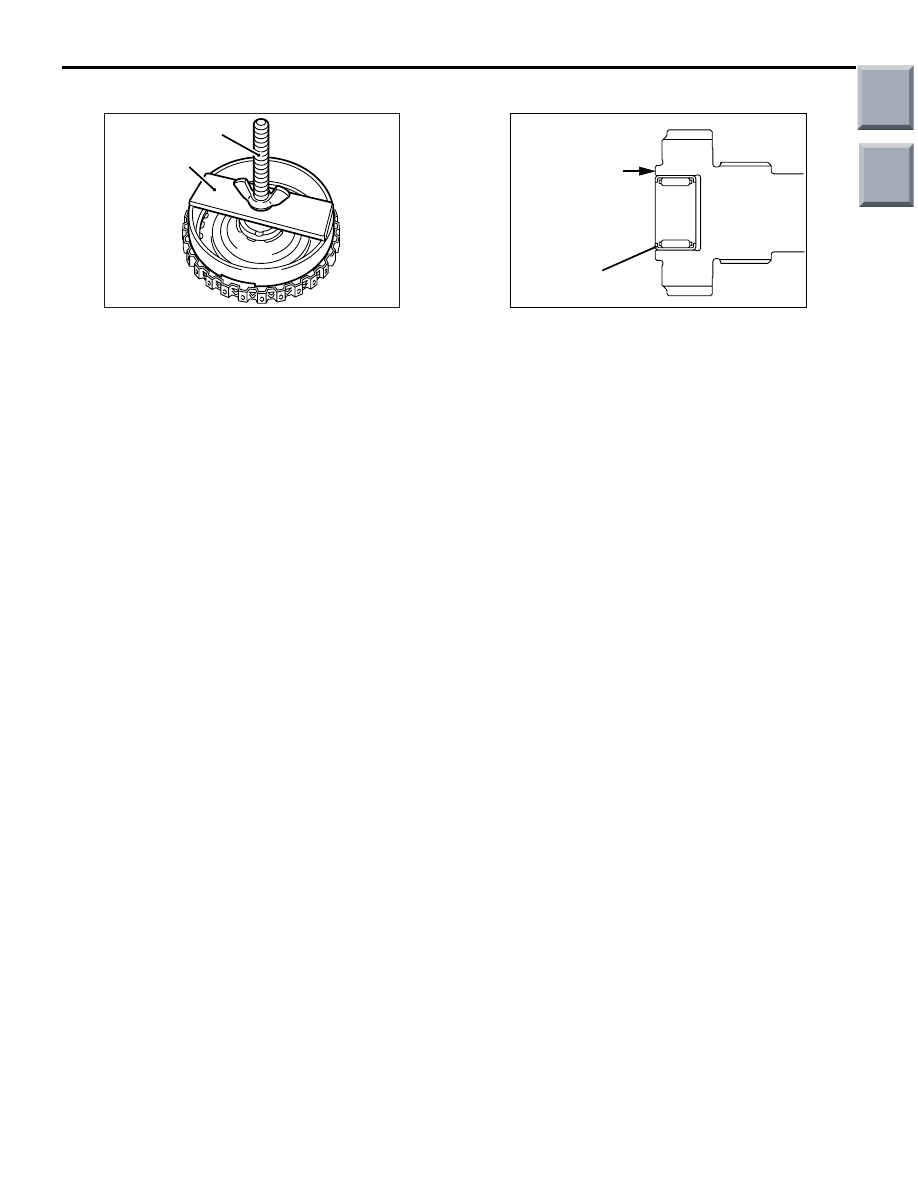

>>D<< SNAP RING INSTALLATION

AK202445

MB991628

MD998924

AC

1. Fit the snap ring in the snap ring groove of the

forward clutch retainer.

2. Press all around the clutch reaction plate using

the special tools.

• Spring compressor retainer (MD998924)

• Spring compressor (MB991628)

3. Check whether the clearance between the snap

ring and clutch reaction plate conforms to the

standard value.

4. If the clearance deviates from the standard value,

adjust it by changing the snap ring to a one of an

appropriate size.

Standard value: 1.2

− 1.4 mm

>>E<< BEARING INSTALLATION

AK202446

A

Stamped mark

side

AC

Press fit the bearing until its stamped mark surface

becomes flush with the surface A shown.

Main

Index

Group

TOC