Mitsubishi Colt Ralliart. Manual - part 283

SNAP RING, SPACER AND THRUST WASHER FOR ADJUSTMENT

CONTINUOUSLY VARIABLE TRANSMISSION OVERHAUL

23B-5

SNAP RING, SPACER AND THRUST WASHER FOR

ADJUSTMENT

M1233204000101

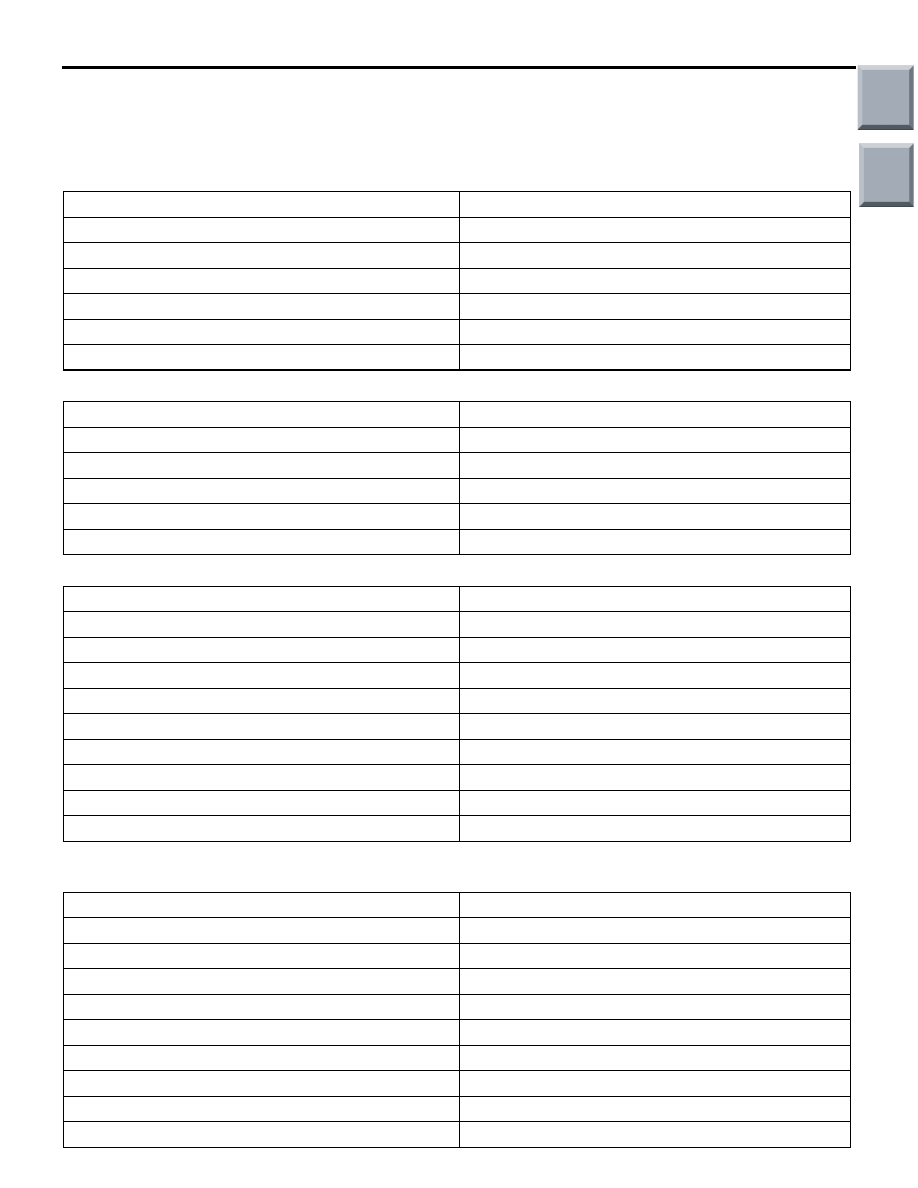

THRUST WASHER (FOR ADJUSTMENT OF INPUT SHAFT END PLAY)

Thickness mm

Identification symbol

1.8

18

2.0

20

2.2

22

2.4

24

2.6

26

2.8

28

SPACER (FOR ADJUSTMENT OF OUTPUT SHAFT END PLAY)

Thickness mm

Identification symbol

1.28

28

1.37

37

1.46

46

1.55

55

1.64

64

SPACER (FOR ADJUSTMENT OF DIFFERENTIAL CASE END PLAY)

Thickness mm

Identification symbol

1.10

J

1.19

L

1.28

N

1.37

P

1.46

R

1.55

T

1.64

V

1.73

X

1.82

Z

SNAP RING (FOR ADJUSTMENT OF FORWARD CLUTCH PISTON END PLAY AND REVERSE BRAKE

PISTON END PLAY)

Thickness mm

Identification color

1.6

None

1.7

Blue

1.8

Brown

1.9

None

2.0

Blue

2.1

Brown

2.2

None

2.3

Blue

2.4

Brown

Main

Index

Group

TOC