Mitsubishi Colt Ralliart. Manual - part 273

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL

00-5

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE

POINTS

CONTENTS OF TROUBLESHOOTING

M1001013300028

CAUTION

During diagnosis, a diagnosis code associated

with other system may be set when the ignition

switch is turned on with connector(s) discon-

nected. On completion, confirm all systems for

diagnosis code(s). If diagnosis code(s) are set,

erase them all.

Troubleshooting of electronic control systems for

which the M.U.T.-III can be used follows the basic

outline described below. Even in systems for which

the M.U.T.-III cannot be used, some of these sys-

tems still follow this outline.

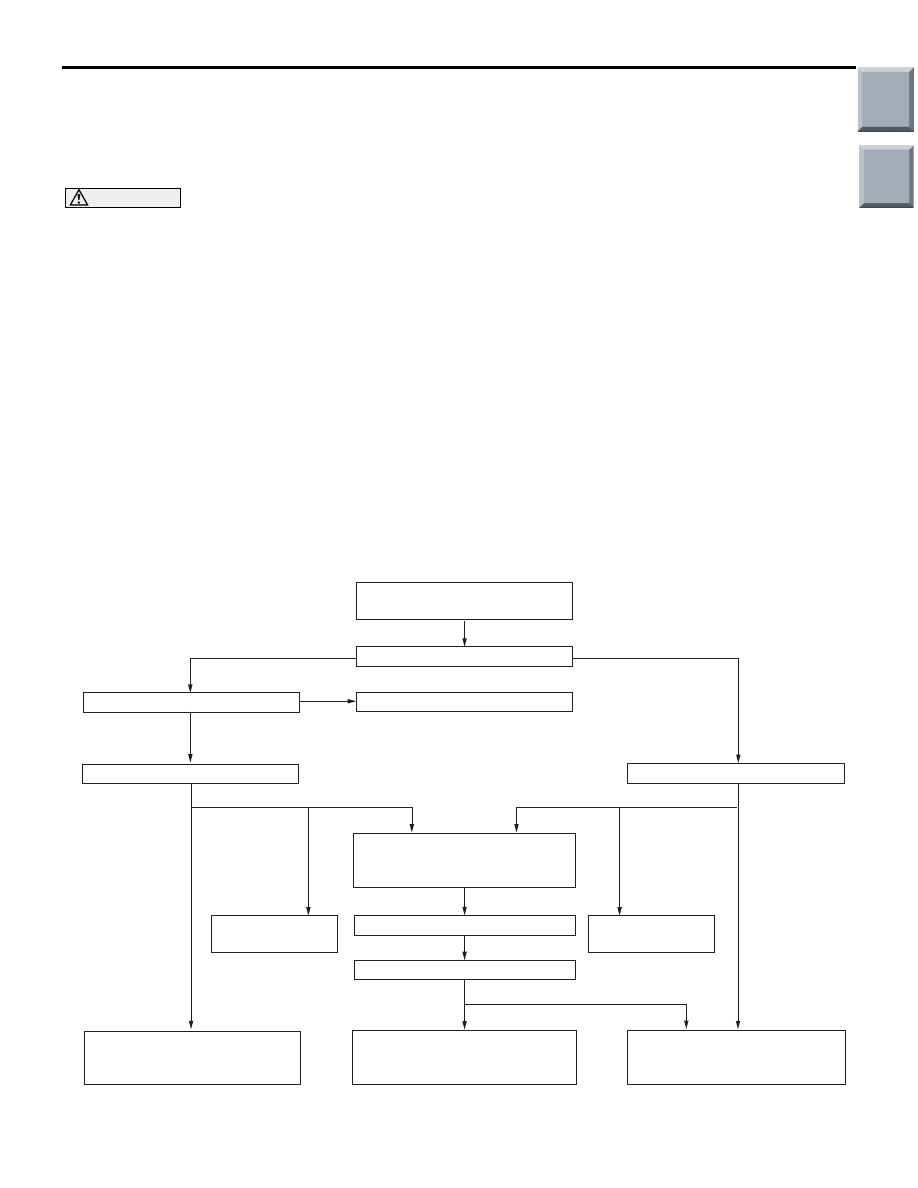

1. STANDARD FLOW OF DIAGNOSIS TROUBLESHOOTING

Troubleshooting sections are based on the diagnostic flow as below. If the diagnostic flow is different from

that given below, or if additional explanation is required, the details of such differences or additions will also

be listed.

Diagnosis method

AC505173

Gathering information

from the customer.

Check trouble symptom.

Reoccurs

Does not reoccur

CAN bus diagnosis chart*

CAN bus diagnosis*

Read the diagnosis code.

Read the diagnosis code.

After taking note of the

malfunction code, erase the

diagnosis code memory.

Recheck trouble symptom.

Read the diagnosis codes.

How to treat past

trouble*

Refer to the INSPECTION CHART

FOR DIAGNOSIS CODES

(Refer to applicable group).

How to treat past

trouble*

Refer to the INSPECTION CHART

FOR TROUBLE SYMPTOMS

(Refer to applicable group).

INTERMITTENT MALFUNCTIONS

*

Diagnosis code

displayed.

(Current trouble)*

Diagnosis code

displayed.

(Current trouble)*

No diagnosis

code.

No diagnosis

code.

Diagnosis code

displayed.

(Past trouble)*

Diagnosis code

displayed.

(Past trouble)*

No diagnosis code

or communication

with M.U.T.-III not

possible

Diagnosis code

displayed.

OK

NG

2

1

3

3

3

3

4

4

5

Main

Index

Group

TOC