Mitsubishi Colt Ralliart. Manual - part 96

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4A9>

13A-338

CAUTION

When shifting the select lever to D range, the brakes should be applied so that the vehicle does not

move forward

NOTE: *1: On the new vehicle (mileage: 500 km or less), injector drive time may be longer by approximately

10%.

NOTE: *2: When service data in check mode is selected, the data is not displayed.

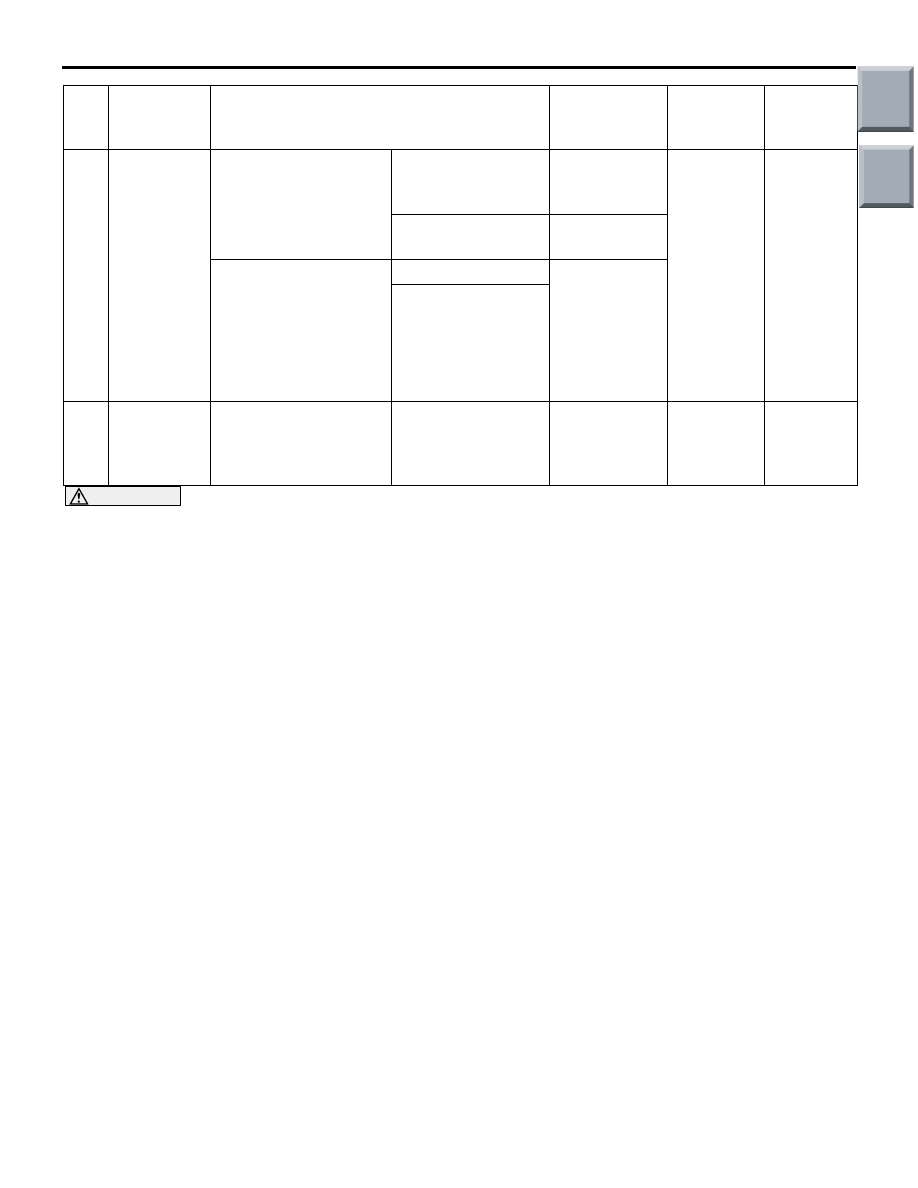

A1

*2

Oxygen

sensor

(front)

Engine: After warm-up

(leaner by deceleration,

richer by acceleration)

Excessive

deceleration from

4,000 r/min

0.2 V or less

Code No.

P0130

At excessive

acceleration

0.6

− 1.0 V

Engine: After warm-up

(using oxygen sensor,

check air-fuel ratio as

well as control status

by engine-ECU <M/T>

or engine-CVT-ECU

<CVT>

Idle operation

0.4 V or less

⇔ 0.6 − 1.0 V

2,500 r/min

A2

*2

Oxygen

sensor

(rear)

Engine: After warm-up At excessive

acceleration

0.2

− 0.8 V

(After several

seconds have

elapsed)

Code No.

P0136

Item

No.

Inspection

item

Inspection condition

Normal

condition

Inspection

procedure

No.

Reference

page

Main

Index

Group

TOC