Mitsubishi Colt Ralliart. Manual - part 40

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4A9>

13A-114

DIAGNOSIS PROCEDURE

STEP 1. M.U.T.-III data list

• Refer to Data List Reference Table

.

a. Item 14: Throttle position sensor (sub)

Q: Is the check result normal?

YES :

Intermittent malfunction (Refer to GROUP

00

− How to Use

Troubleshooting/Inspection Service Points

−

How to Cope with Intermittent Malfunctions

).

NO :

Go to Step 2 .

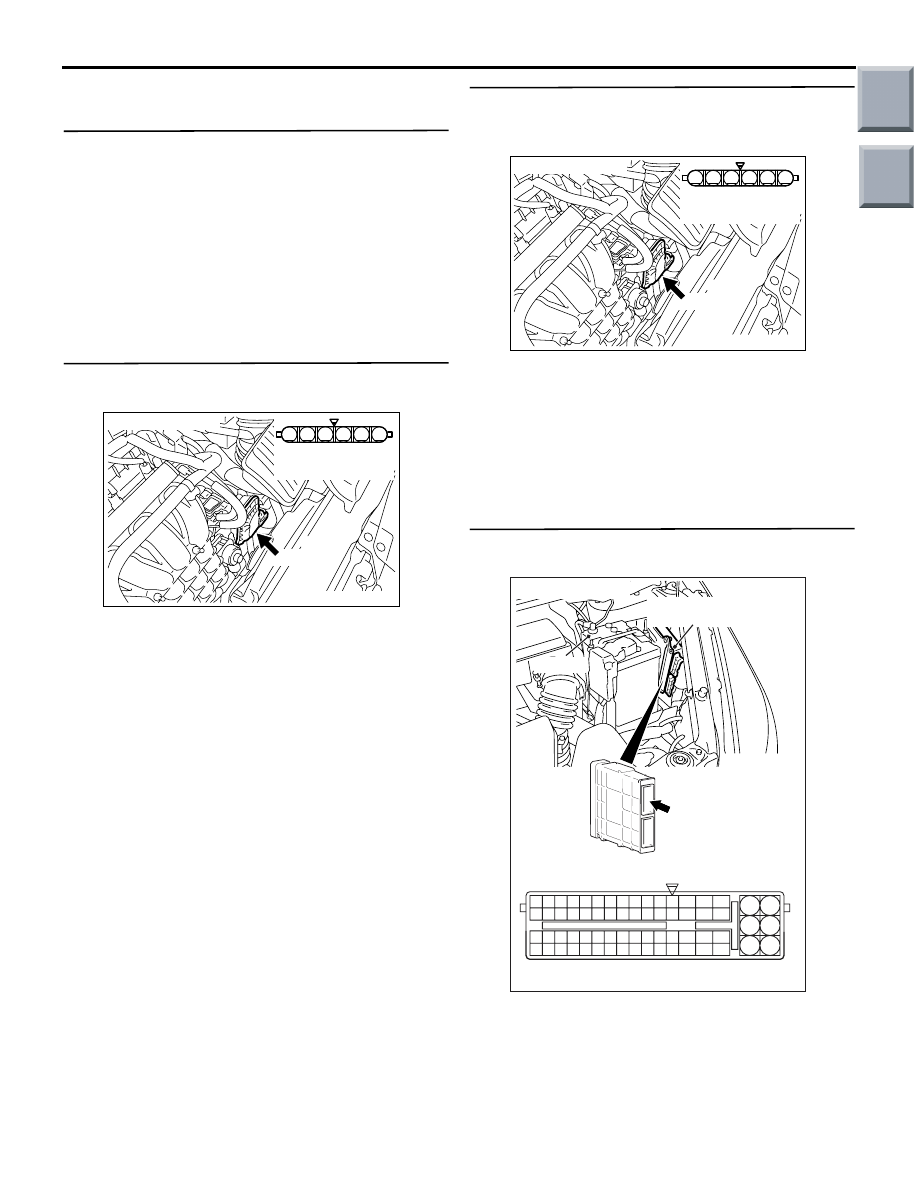

STEP 2. Connector check: A-107

electronic-controlled throttle valve connector

Q: Is the check result normal?

YES :

Go to Step 3 .

NO :

Repair or replace the connector.

STEP 3. Perform resistance measurement at

A-107 electronic-controlled throttle valve

connector.

• Disconnect connector, and measure at harness

side.

• Resistance between terminal No. 3 and earth.

OK: Continuity (2

Ω or less)

Q: Is the check result normal?

YES :

Go to Step 7 .

NO :

Go to Step 4 .

STEP 4. Connector check: A-114 engine-ECU

connector or engine-CVT-ECU connector

Q: Is the check result normal?

YES :

Go to Step 5 .

NO :

Repair or replace the connector.

AK402006

1

6 5 4 3 2

AC

A-107 (B)

Connector: A-107

A-107 Harness side

connector

AK402006

1

6 5 4 3 2

AC

A-107 (B)

Connector: A-107

A-107 Harness side

connector

AK402745

6

4

2

5

3

1

9

7

8

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

L

AD

A-114

Connector:

A-114

Harness side connector

Engine-ECU <M/T> or

engine-CVT-ECU <CVT>

Battery

Main

Index

Group

TOC