Mitsubishi Colt Ralliart. Manual - part 25

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4A9>

13A-54

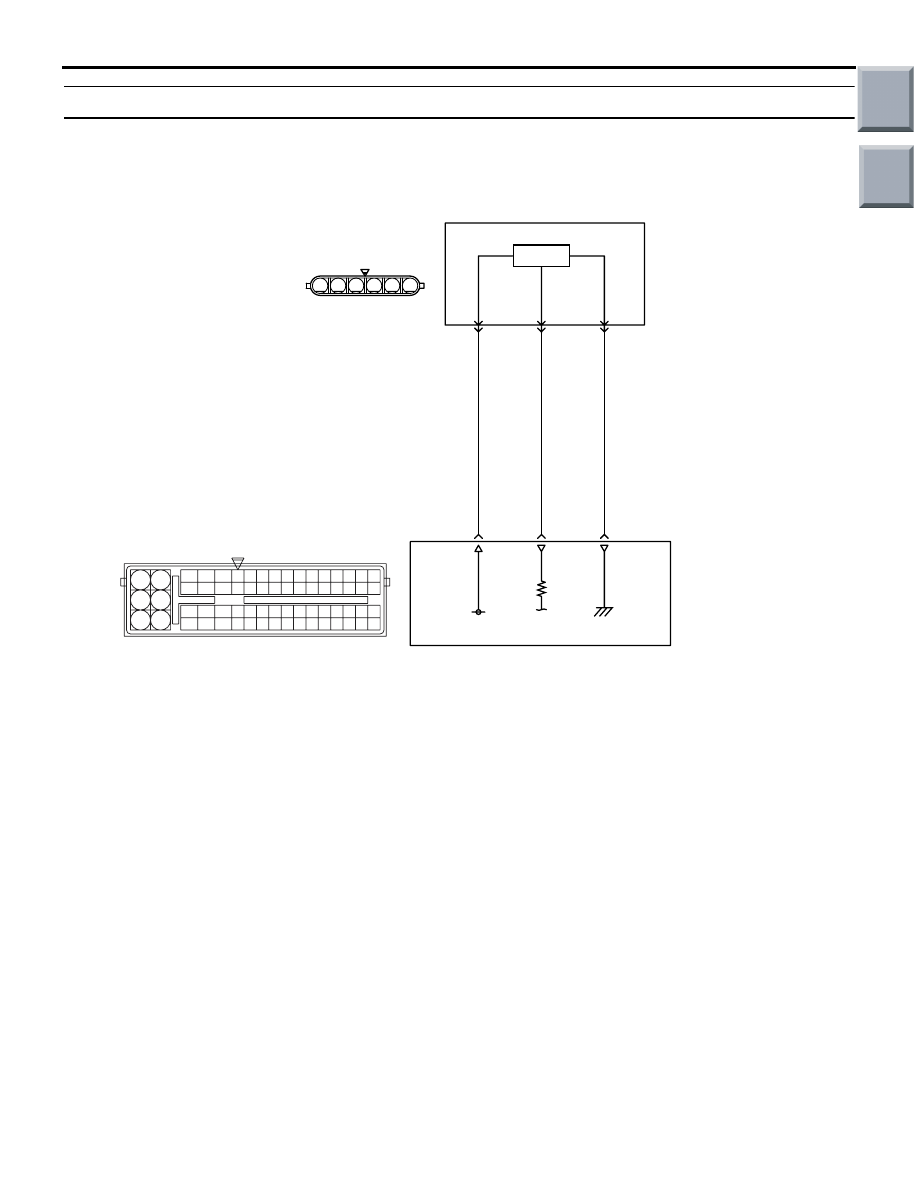

Code No. P0123: Throttle Position Sensor (Main) Circuit High Input

OPERATION

• A power voltage of 5 V is applied to the elec-

tronic-controlled throttle valve (terminal No. 5)

from the engine-ECU <M/T> or engine-CVT-ECU

<CVT> (terminal No. 31).

• The power voltage is earthed to the engine-ECU

<M/T> or engine-CVT-ECU <CVT> (terminal No.

30) from the electronic-controlled throttle valve

(terminal No. 3).

• The sensor signal is inputted to the engine-ECU

<M/T> or engine-CVT-ECU <CVT> (terminal No.

15) from the electronic-controlled throttle valve

output terminal (terminal No. 6).

FUNCTION

• The throttle position sensor converts the throttle

valve position into voltage and inputs it into the

engine-ECU <M/T> or engine-CVT-ECU <CVT>.

• The engine-ECU <M/T> or engine-CVT-ECU

<CVT> controls the throttle valve position.

TROUBLE JUDGMENT

Check Condition

• Ignition switch is in "ON" position.

Judgment Criteria

• Throttle position sensor (main) output voltage is

4.8 V or more <M/T>.

• Throttle position sensor (main) output voltage is

4.8 V or more for 0.5 second <CVT>.

PROBABLE CAUSES

• Failed throttle position sensor (main)

• Open/short circuit in throttle position sensor cir-

cuit or loose connector contact

• Failed engine-ECU <M/T> or engine-CVT-ECU

<CVT>

AK402679

6

1 2 3 4 5

19

21

20

18

17

16

15

14

1213

11

8 9

L

10

37

52 53 54 555657585960616263646566

38 39 404142434445464748495051

22 23 24 252627282930313233343536

7

5

3

1

6

4

2

5 V

31

5

Electronic-controlled

throttle valve

B-W

R-W

Y-R

Engine-ECU <M/T> or

engine-CVT-ECU <CVT>

15

30

6

3

Throttle Position Sensor (main) Circuit

A-107

A-114

(main)

Hall IC

AE

Wire colour code

B: Black LG: Light green G: Green L: Blue W: White Y: Yellow SB: Sky blue BR: Brown O: Orange GR: Gray

R: Red P: Pink V: Violet Pu: Purple

Main

Index

Group

TOC