Mitsubishi 380. Manual - part 966

ON-VEHICLE SERVICE

ANTI-LOCK BRAKING SYSTEM (ABS)

35B-89

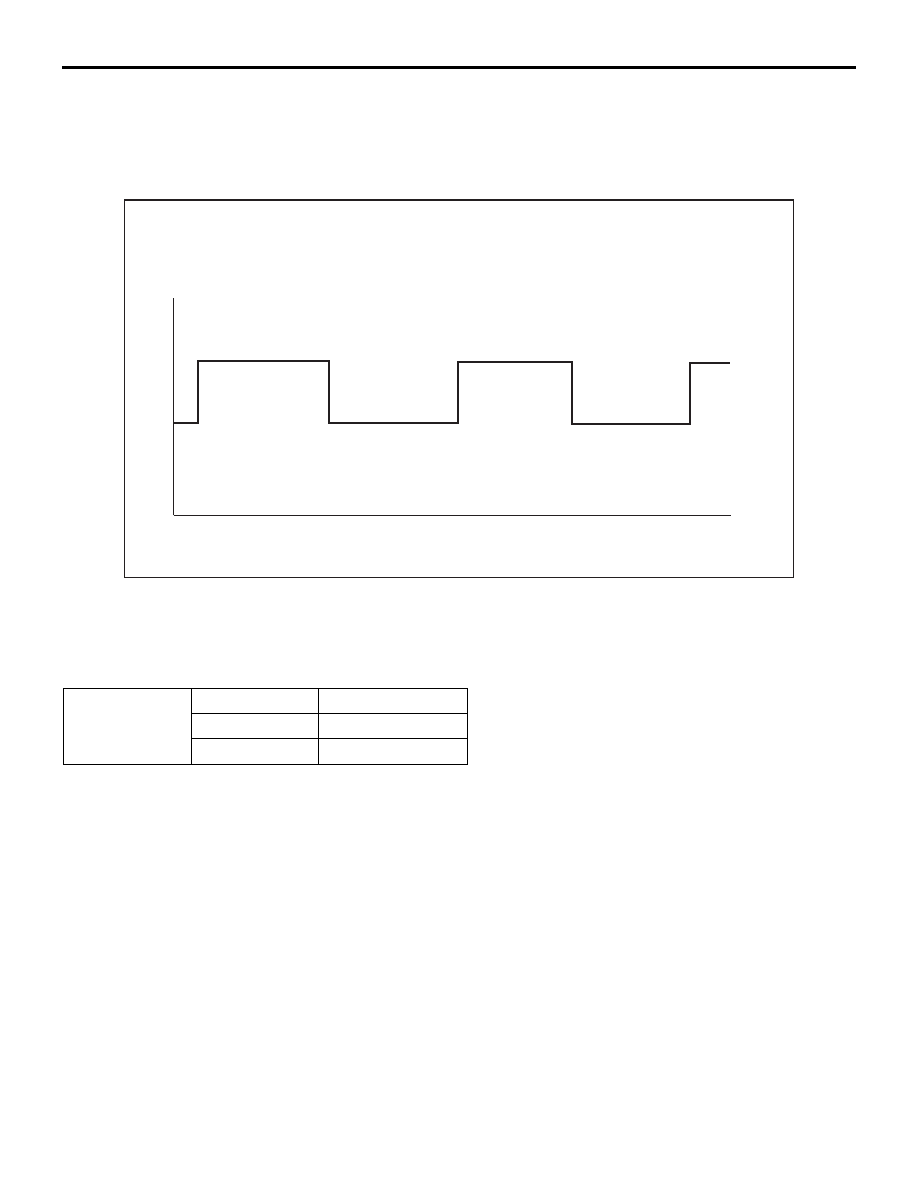

6. Turn wheel by hand at approximately 1 revolution per

second (r/sec) or drive on brake dynamometer at 5km/h.

Recommended Oscilloscope setting:

• Y-axis: 2Volts

• X-axis: 100ms

NOTE: If the oscilloscope signal shape is correct and wheel

sensor air gap is within specification, but the voltage values are

either higher or lower as shown in the table below, the wheel

speed sensor must be changed.

Probable causes of low output voltage

• Wheel speed sensor pole piece to wheel speed rotor clear-

ance too large

• Faulty wheel speed sensor

7. To observe the waveform with an oscilloscope:

• Front and Rear Wheels: Turn the wheels manually at a con-

stant speed

NOTE: The output voltage will remain same regardless of

vehicle speed.

.

NOTE: The wheel speed sensor cable moves in relation to motion of the front or rear suspension. Therefore,

it is likely that it has an open circuit only when driving on rough roads but it functions normally when driving on

smooth roads. It is recommended to observe sensor signal waveform also under special conditions, such as

driving on a rough road.

1.50

1.00

0.50

0.00

U-CH1

0

20

40

60

80

100

ms

V

Test Procedure: Universal Oscilloscope

FIGURE 3

35DB120A

Wheel speed

sensor

Standard

Value

High

0.9V - 1.5V

Low

0.3V - 0.8V