Mitsubishi 380. Manual - part 845

ON-VEHICLE SERVICE

REAR SUSPENSION

34-6

ON-VEHICLE SERVICE

REAR WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1341011000394

Measure wheel alignment with an alignment equipment on

level ground.

The rear suspension and tyres should be serviced to the nor-

mal condition prior to wheel alignment measurement.

.

CAMBER

Standard value:

− 0° 50’ ± 30’ (Left/right deviation within 30’)

NOTE: For vehicles with aluminum wheels, attach the cam-

ber/caster/kingpin gauge by using a compensator.

.

TOE-IN

Standard value: 3

± 3 mm (0.12 ± 0.12 inch)

.

If camber and/or toe-in is not within the standard value, adjust

by the following procedures.

CAUTION

• When adjusting the camber, tighten the lower arm

assembly and the trailing arm assembly, not the toe

control arm.

• After adjusting the camber, be sure to adjust the toe.

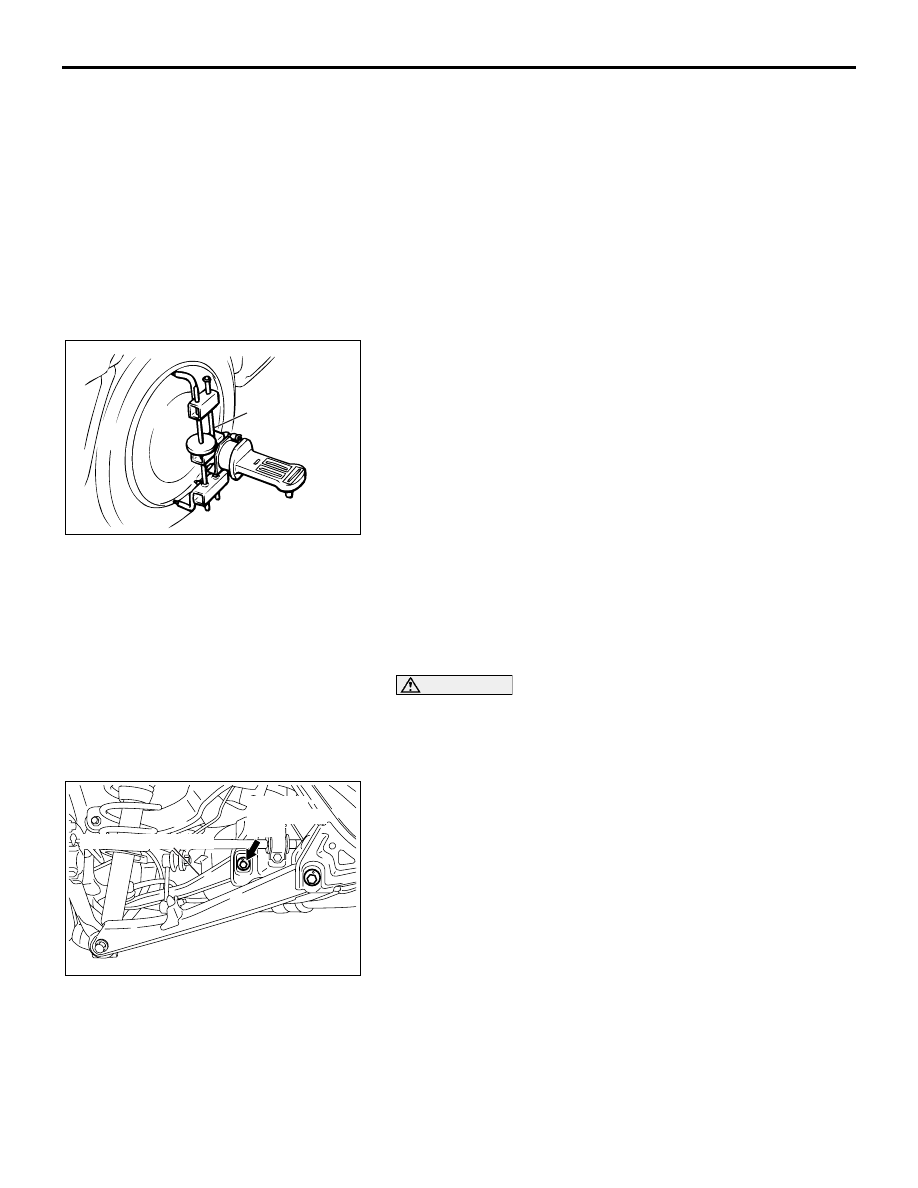

1. Carry out camber adjustment by turning the camber

adjusting bolt.

NOTE:

.

• LH: Clockwise viewed from the rear → (−) camber

• RH: Clockwise viewed from the rear → (+) camber

• If either the camber or toe is adjusted, both should fluctu-

ate. For the relationship between the two, refer to CAM-

BER AND TOE REFERENCE TABLE (Refer to

).

AC305848 AB

COMPENSATOR

AC305842

AB

TOE CONTROL ARM

CAMBER

ADJUSTING

BOLT