Mitsubishi 380. Manual - part 758

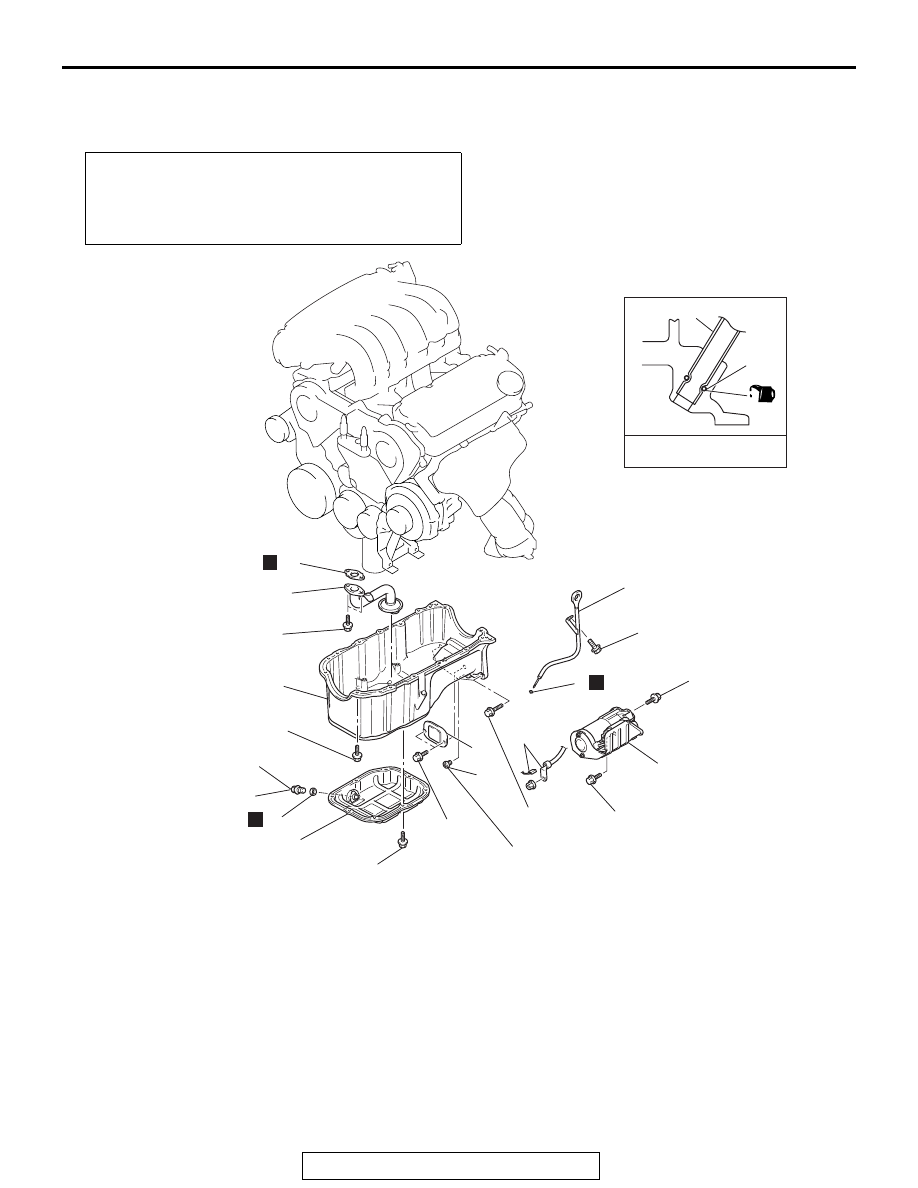

OIL PAN AND OIL SCREEN

TSB Revision

ENGINE MECHANICAL <3.8L ENGINE>

11A-34

OIL PAN AND OIL SCREEN

REMOVAL AND INSTALLATION

M1112002500193

Pre-removal and Post-installation Operation

• Under Cover Removal and Installation (Refer to GROUP

51, Under Cover

.)

• Engine Oil Draining and Refilling (Refer to GROUP 12,

On-vehicle Service

.)

AC308673

1

2

3

4

5

6

7

8

9

10

11

12

11 ± 0.5 N·m

93 ± 4 in-lb

49 ± 3 N·m

36 ± 2 ft-lb

35 ± 5 N·m

26 ± 4 ft-lb

30 ± 3 N·m

23 ± 2 ft-lb

30 ± 3 N·m

23 ± 2 ft-lb

14 ± 1 N·m

120 ± 13 in-lb

11 ± 1 N·m

97 ± 9 in-lb

39 ± 5 N·m

29 ± 3 ft-lb

19 ± 3 N·m

14 ± 2 ft-lb

8.5 ± 3.5 N·m

76 ± 31 in-lb

N

N

N

AB

6

5

ENGINE OIL

REMOVAL STEPS

1.

ENGINE OIL PAN DRAIN PLUG

2.

ENGINE OIL PAN DRAIN PLUG

GASKET

3.

STARTER CONNECTOR

4.

STARTER ASSEMBLY

5.

ENGINE OIL DIPSTICK

ASSEMBLY

6.

O-RING

<<A>>

>>B<<

7.

ENGINE LOWER OIL PAN

•

FRONT NO.1 EXHAUST PIPE

(REFER TO GROUP 15,

EXHAUST PIPE AND MAIN

MUFFLER

8.

COVER

<<B>>

9.

TORQUE CONVERTER

CONNECTING BOLT

<<C>>

>>A<<

10. ENGINE UPPER OIL PAN

11. OIL SCREEN

12. GASKET

REMOVAL STEPS (Continued)