Mitsubishi 380. Manual - part 682

DIAGNOSIS

CONTROLLER AREA NETWORK (CAN)

54C-138

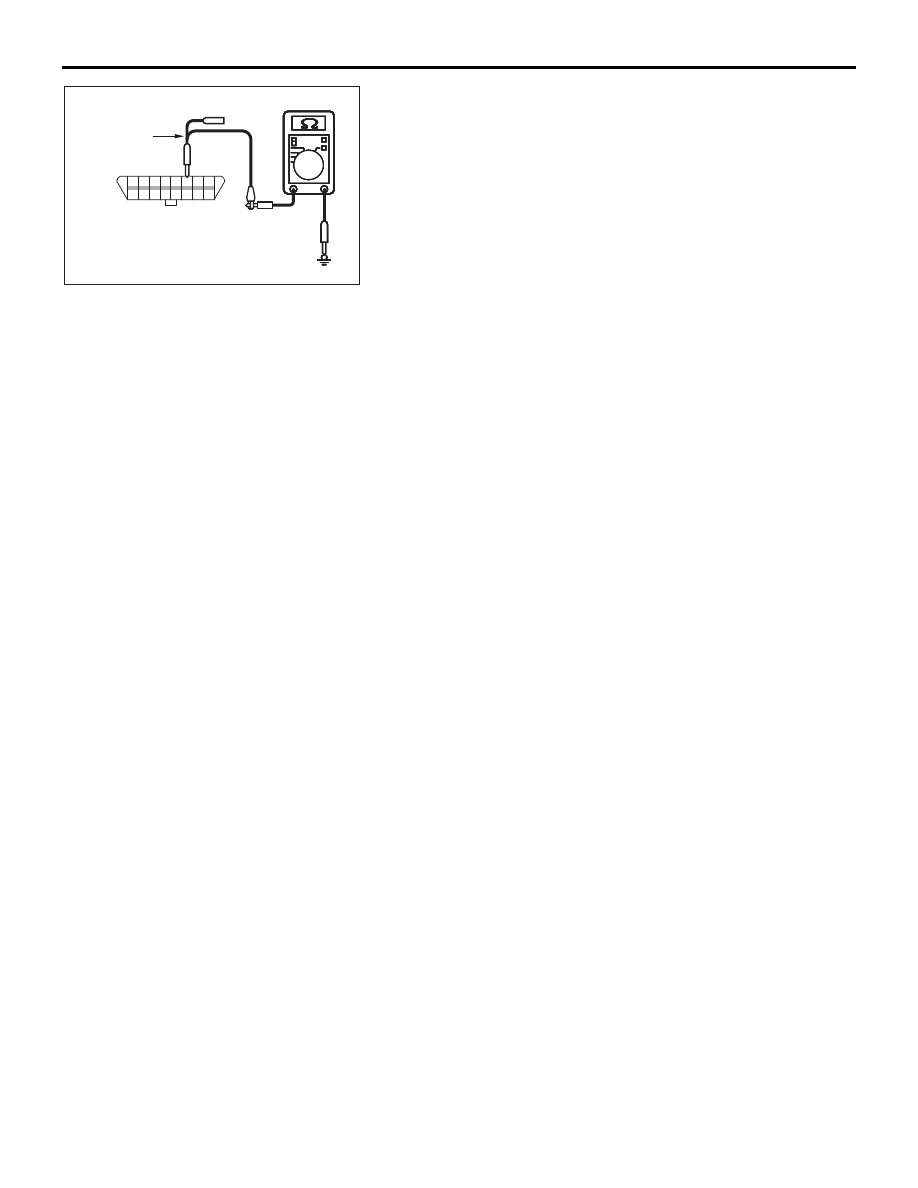

(4) Measure the resistance between data link connector

terminal 6 and body ground.

OK: 1 k

Ω or more

Q: Does the resistance measure 1 k

Ω or more?

YES : If the resistance measures 1 k

Ω or more, go to Step 3

.

NO : If the resistance measures less than 1 k

Ω, go to Step

AC209364

Y

8

16

15

7

5

1314

6

12

4

2

1011

3

9

1

AC209364

AC209364

AC209364

AC209364

AC209364HT

HARNESS SIDE: C-125

TEST

HARNESS