Mitsubishi 380. Manual - part 643

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MPI) <3.8L ENGINE>

13A-664

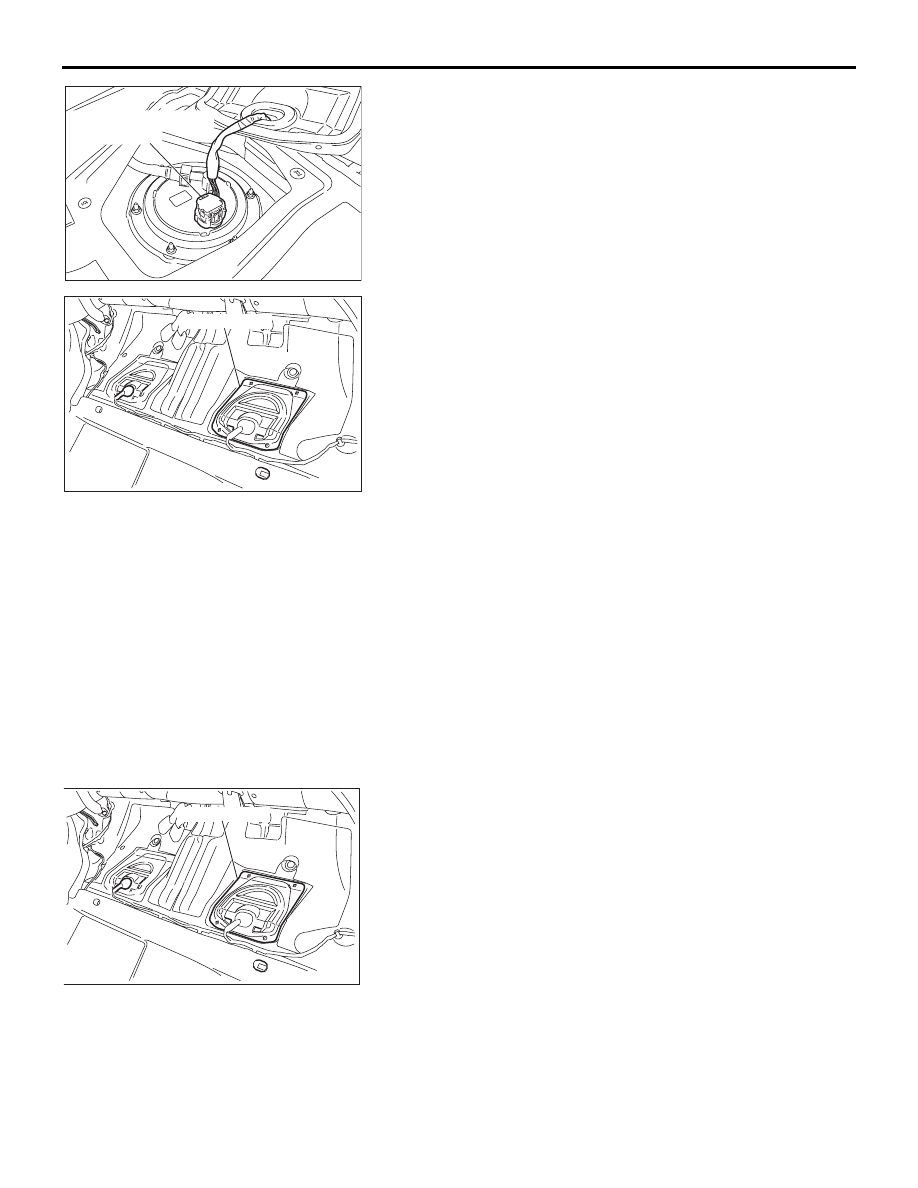

3. Disconnect the fuel pump module connector.

4. After starting the engine and letting it run until it stops

naturally, turn the ignition switch to the "LOCK" (OFF)

position.

5. Connect the fuel pump module connector.

6. Install the hole cover (LHS).

Tightening torque: 1.5

± 0.5 N⋅m (14 ± 4 in-lb)

7. Install the rear seat cushion assembly (Refer to GROUP

52A, Rear Seat Assembly

FUEL PUMP OPERATION CHECK

M1131002000692

1. If the fuel pump will not operate, check by using the

following procedure. If normal, check the fuel pump drive

circuit.

(1) Turn the ignition switch to "ON". Listen for fuel pump

running for approximately 2 seconds. Pump will

automatically stop after this time.

NOTE: As the fuel pump is an in-tank type, the fuel pump

sound is hard to hear. Remove the fuel tank filler tube cap

and check from the tank inlet.

(2) Remove the rear seat cushion assembly (Refer to

(3) Remove the hole cover (LHS).

AC306490

FUEL PUMP MODULE

CONNECTOR

AB

03DB150A

HOLE COVER

03DB150A

HOLE COVER