Mitsubishi 380. Manual - part 454

OIL PAN AND OIL PUMP

ENGINE OVERHAUL <3.8L ENGINE>

11B-42

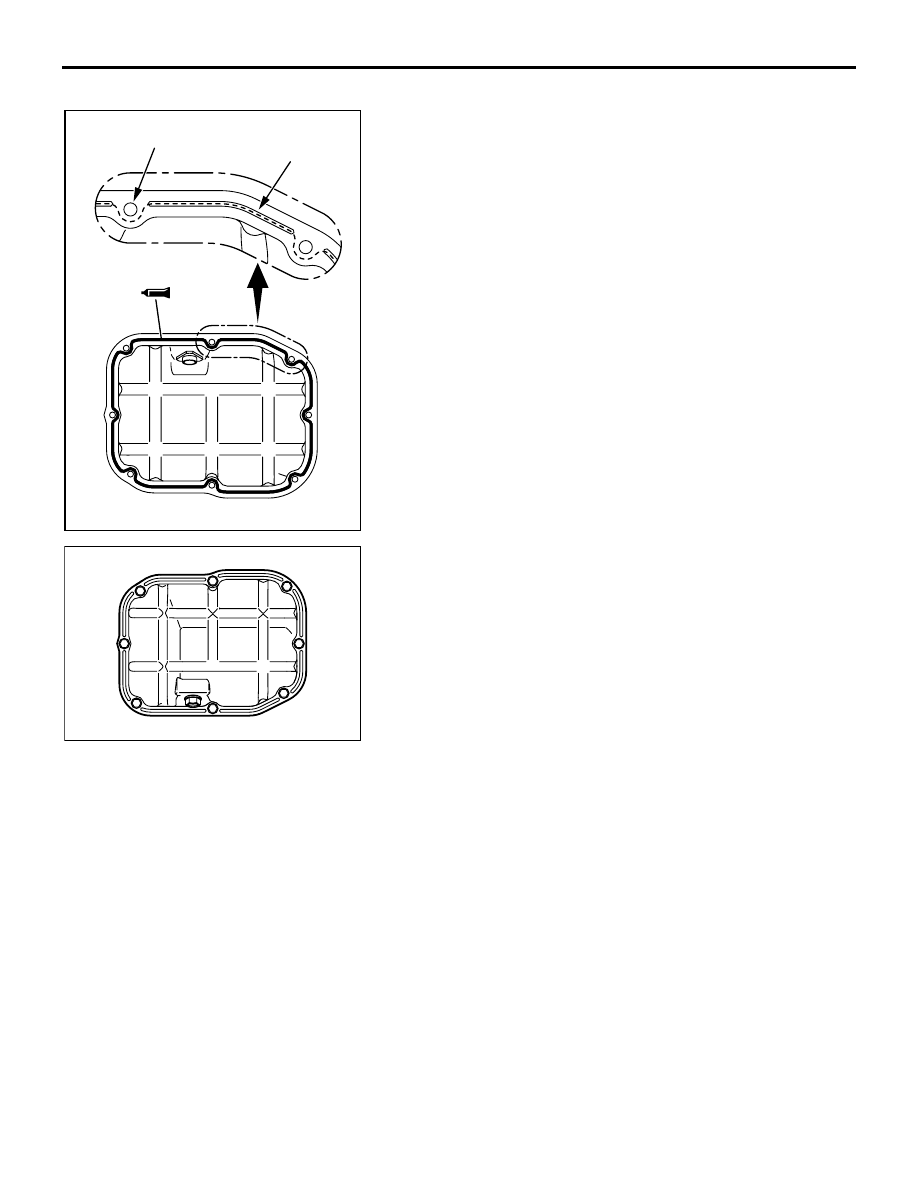

>>G<< OIL PAN, LOWER INSTALLATION

1. Clean both gasket surfaces of the upper and lower oil pans.

2. Apply a 4 mm (0.2 inch) diameter bead of sealant

(Mitsubishi Genuine Parts number MD970389 or equivalent)

to the lower oil pan.

Apply sealant as indicted by the broken line in the

illustration; the grooves must be traced and the bolt holes

must be surrounded with a bead of sealant.

3. Install the lower oil pan to the upper oil pan.

NOTE: Be sure to install the oil pan quickly while the sealant

is wet (within 15 minutes).

4. Tighten the lower oil pan bolts in the sequence shown.

Tightening torque: 11

± 1 N⋅m (95 ± 9 in-lb)

NOTE: After installation, keep the sealed area away from oil

for approximately one hour.

.

AK302911AB

GROOVE

BOLT HOLE

AK204036AB

4

7

3

1

5

8

6

2